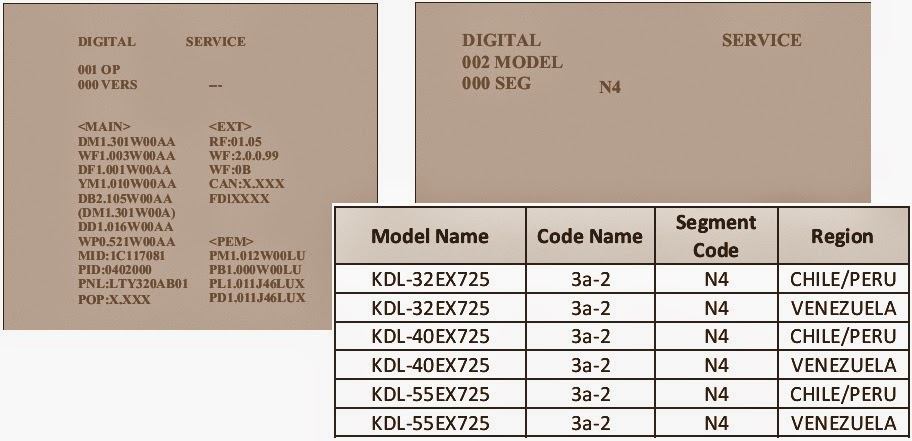

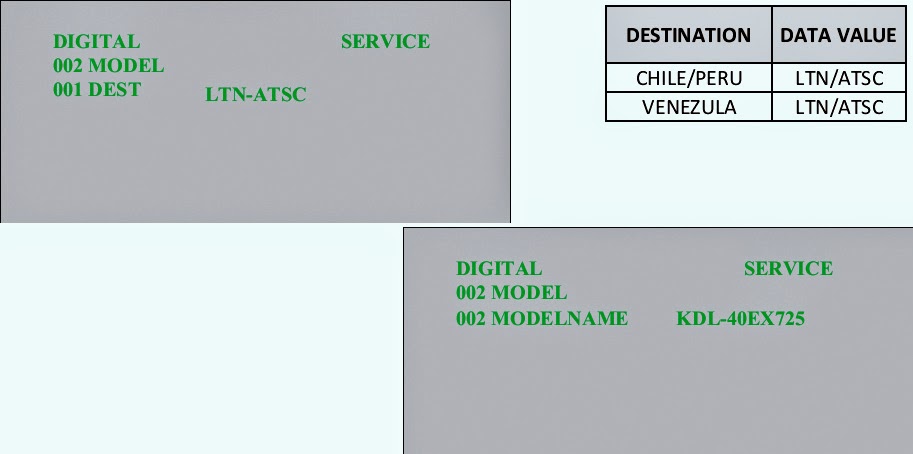

KDL-32EX725 RM-YD062 CHILE/PERU | KDL-32EX725 RM-YD062 VENEZUELA

KDL-40EX725 RM-YD062 CHILE/PERU | KDL-40EX725 RM-YD062 VENEZUELA

KDL-55EX725 RM-YD062 CHILE/PERU | KDL-55EX725 RM-YD062 VENEZUELA

LED Blinking Codes [Error Codes] & Self Check Function

If an error occurs, the standby LED will automatically begin to flash. The number of times the LED flashes translates to a probable source of the problem.

If there is more than one error, the standby LED will identify the first of the problem areas. If the Self check screen displays a “0”, no error has occurred.

2X Blink - Main Power Error: A 2X protection mode blink pattern can be activated due one of the following defects.

* Loss of REG12V (LVP)*

* Loss of -125V (Single Line)

* Excessive -125V Level (OVP)*

* Loss of Power-ON Signal

* Excessive PFC Voltage (OVP)

* Excessive PFC Temperature (OTP)

# Low Voltage Protection (LVP)

# Over Voltage Protection (OVP)

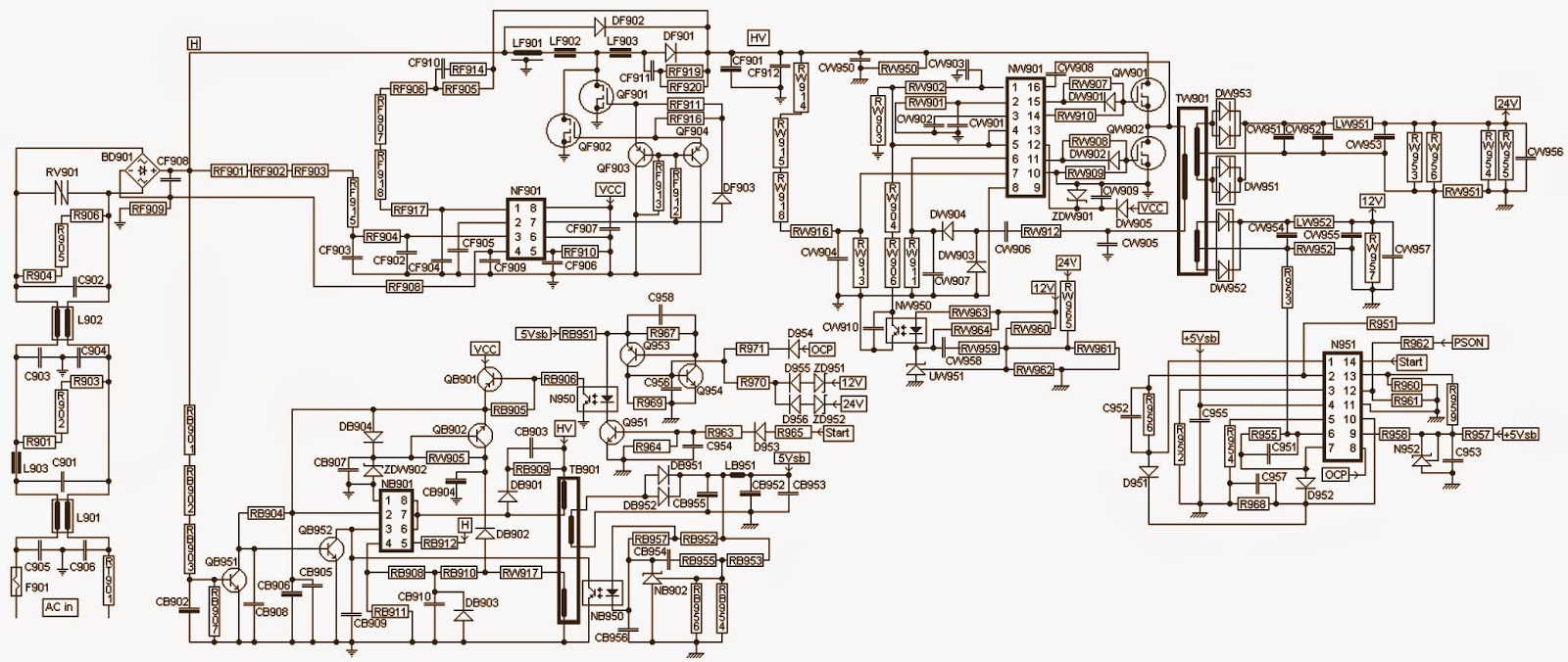

A loss or excessive condition of the REG12VDC secondary voltage from the main power supply IC6351 will cause a 2X blink pattern on the standby LED. The 12Vdc can be checked at CN6704/pin 16. If the measurement is 0V or rises above 12Vdc (approaches 15V) before the TV shuts down the Power Supply Board is defective. If approximately 12Vdc is present and remains below 12Vdc before shutdown then further troubleshooting is necessary to determine the defective component. After confirming proper REG12V levels, check the Negative LED Backlight supply levels. A loss or excessive condition of the negative supply will cause a 2X blink failure. The voltage level can be checked at CN6701/pins 1 & 3 before the TV shuts off. There will be 2 to 4 wires (Red & Blue) depending on the panel size. All individual wires should be checked for proper voltage level. In normal operation the voltage level will initially rise to approximately -175V and then should

Regulate down to between 89V and 125V depending on the Back light adjustment in the User Menu. If one of the negative supplies is 0V or rises above -175V before shut-off then the Power Supply Board is defective, replace it to fix the problem. A defective X-Reality processor on the Main Board or Switch circuit on the Power Supply Board will cause a loss of the Power-ON signal (2X). To determine which component is defective check the Power-ON voltage level at CN6704/pin 1. In normal operation 3V should be measured. If the 3V is present before shut-off then the Power Supply Board is defective. If 0V is measured before shut-off then the Main Board is defective. Finally, there are PFC protection circuits on the Power Supply Board that when activated will cause a 2X blink protection mode. The PFC circuit is monitored for both over-voltage and over-temperature. Therefore, if all the previously discussed circuits checkout okay, there could still be a problem on the Power Supply Board in the PFC circuit causing the 2X blink. Replacing the Power Supply Board will fix the TV.

3X Blink- DC Regulator/Audio Error: The Audio error can occur due on of the following error conditions.

Defective DC Regulator on Main Board

Shorted or Damaged Speaker Connections

Defective Audio Amplifier (Main Board)

Loss of AU12V (Open F4200 on Main Board)

Loss of AU12V (Open Fuse on Power Supply Board)

The first thing to check when a 3X blink protection mode occurs is the physical condition of the speakers and speaker connections. The speakers should measure 8 ohms. Shorted speakers or connections can cause a 3X blink protection mode. If the speakers and connections check okay, then the defective component is on the Main Board. An open F4200, defective DC Regulator, or defective Audio amplifier will cause a 3X blink protection mode. In any of these cases, replace the Main Board to fix this condition. A defect on the Power Supply Board can cause a 3X blink protection mode and shut-off. Check the AU12V level at CN6704/pin 14. If 0V is measure before 4X Blink – Balancer Error.

The 4X error code is only used on models incorporating local dimming LED back-lighting. If a failure occurs on the LD board the TV will shut down and display this diagnostic code. Models using conventional non-local dimming LED back-lighting do not utilize this error code.re shut-off the Power Supply Board is defective.

5X Blink - T-CON Error

The 5X blink protection mode indicates a communications error between the T-CON Board and the X-Reality microprocessor on the Main Board. If the T-CON is available for replacement, replace the T-CON. If the T-CON is not available, the LCD panel must be replaced since the T-CON circuit is part of the LCD panel assembly. In rare cases a loose or defective LVDS cable could also be the cause.

6X Blink - Back-light System Failure

NOTE: All models will make two attempts to power up before a 6X is activated. The SONY logo (Back-light) may or may not display on the screen. However, the splash tones will be heard two times. After the second attempt the TV will turn off and the standby LED will blink a 6X protection mode. (Note: The splash tone may not be heard if it is turned off or the volume is set to minimum.) If a 6X blink pattern is activated then a defect has occurred in one of the following areas.

* Defective Panel LED(s)

* Defective Power Supply

When troubleshooting a 6X back-light system failure it is key to notice if the back-lights illuminate before the TV shuts off. The following list shows the possible back-light status and blink pattern and the possible failed components.

1. Momentary Back-light and 6X: Defective LED(s) (LCD Panel Assy.)

2. No Backlight and 6X: Replace Power Supply

In most cases, if the Sony logo (Back-light) momentarily illuminates and the TV shuts off and a 6X is activated than one or more of the back-light LEDs are defective. The LCD Panel assembly panel must be replaced for a defective LED. However, before replacing the LCD panel assembly checks for a complete loss of the Negative Back-light (-89V to -125V) power supply. The -89V to -125V power supply can be checked at CN6702/pins 1 & 3.

If there is no back-light before the TV shuts off and activates a 6X, than check the “Back-light ON” signals from the TV microprocessor and the Positive (+145V) Back-light power supply from the Power Supply Board. The BL-ON signal can be checked at CN6704/pin 5 and the +145V at CN6701/pins 1 & 3. If the “Back-light-ON” signal is okay and the Positive Power supply is missing then the Power Supply Board is defective. However, if the Back-light-ON is missing then the X-Reality Microprocessor is defective and the Main Board must be replaced to repair the problem.

7X Blink - Temperature Failure

These models do not display a temperature warning OSD dialogue box before shutting off and going into a 7X standby LED blink pattern. The main objective when a 7X blink pattern occurs is to determine which of the following possible defects is causing the excessive temperature condition indication.

Excessive Ambient Room Temperature

Dust or Debris Blocking the TV Ventilation Apertures

Defective Temperature Sensor or X-Reality Microprocessor (Main Board) The first step is to notice how long it takes the TV to shut off and trigger a 7X blink protection mode. If the TV has an actual excessive temperature condition it will take a considerable period of time to shut off and indicate a 7X blink protection mode. This is because it will take time for the TV components to heat up and for the temperature sensor to detect the excessive temperature and shut the TV off.

If the TV takes a considerable period of time to shut-off check the following items:

* The TV should not be located too close to any heating devices.

* The TV should have at least 4 inches of clearance around the sides & rear, and 11 inches of clearance over the top to ensure adequate ventilation.

* Check that all vented areas on the TV are clear of all dust and debris.

* If the TV shuts off immediately after Power-ON then one of the following components has failed (Not an Actual Excessive Temperature Condition).

# X-Reality Microprocessor (Main Board)

# Temperature Sensor (Main Board)

In either case the Main Board must be replaced to fix the problem.

The Diagnostic Table provides an overview of the number of times the standby LED blinks and the possible location.

VIEWING THE SELF CHECK DIAGNOSTIC HISTORY

It is possible to bring up past occurrences of a failure for confirmation on the Self Check diagnostic history screen. This feature is useful for failures which are intermittent or when the customer is not sure what is causing the television to shut down.

* TV must be in standby mode. (Power off).

* Press the following buttons on the Remote Commander within a second of each other:

DISPLAY > CHANNEL-5 > VOLUME-[--] > POWER

* NOTE: This differs from accessing Service Adjustments Mode (Volume +)

CLEARING THE SELF CHECK DIAGNOSTIC LIST

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen after you have completed the repairs to be sure you have cleared the result display to “0”.

To clear the Error history and Error count press { 8 > 0 }.

RESETTING THE LCD PANEL OPERATING HOURS

The 3 sets of numbers displayed on the lower left corner of the screen indicates the total accumulated operating hours of the television and the operating hours of the LCD panel. Total operating hours is on the left, boot count in the centre and panel hours in the right group (The centre numbers are not used.)

To clear the LCD Panel operating hours of the LCD Panel after replacing the panel, press {7 > 0}

EXITING THE SELF CHECK DIAGNOSTIC SCREEN

To exit the Self Diagnostic screen, turn off the power to the TV by pressing the POWER button on the remote or the POWER button on the TV.

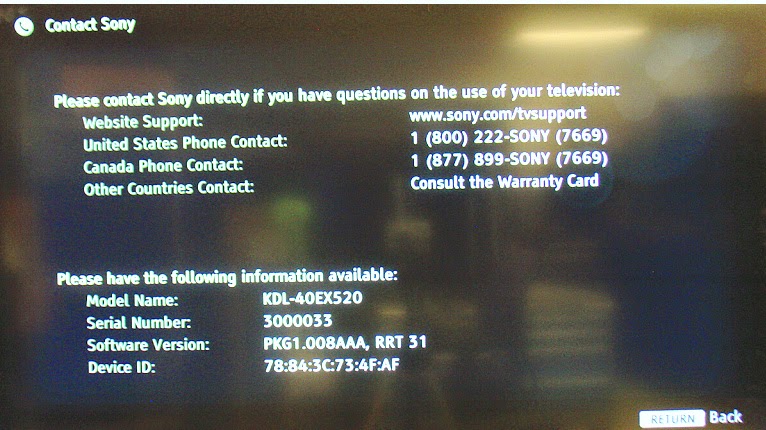

SELF CHECK SCREEN DISPLAY

CLICK ON THE PICTURES TO MAGNIFY