Sanyo Multimedia ProjectorPLC-XW20, PLC-SW20

(U.S.A., Canada, Europe, Asia, Africa U.K.)

ORIGINAL VERSION Chassis No. MW6-XW2000 (PLC XW20), MZ6 SW2000 (PLC SW20)

Lamp replacement

When the life of Projection Lamp of this projector draws to an end, LAMP REPLACEMENT indicator lights yellow.

When a projected image becomes dark or the color of an image becomes unnatural, replacement of Projection Lamp is required.

Allow a projector to cool for at least 45 minutes before you open Lamp Cover.

The inside of a projector can become very hot.

The inside of a projector can become very hot.

Turn off the projector and disconnect AC plug. Allow the projector to cool for at least 45 minutes.

2. Remove a screw with a screwdriver to remove Lamp Cover.

3. Remove 2 screws with a screwdriver and pull out Lamp Assembly by grasping Handle.

4. Replace Lamp Assembly with a new one and tighten 2 screws back. Make sure that Lamp Assembly is set properly. Replace Lamp Cover and tighten a screw.

5. Connect AC Power Cord to the projector and turn it on.

6. Reset Lamp Replace Counter (refer to the section “Lamp Replace Counter” below).

2. Remove a screw with a screwdriver to remove Lamp Cover.

3. Remove 2 screws with a screwdriver and pull out Lamp Assembly by grasping Handle.

4. Replace Lamp Assembly with a new one and tighten 2 screws back. Make sure that Lamp Assembly is set properly. Replace Lamp Cover and tighten a screw.

5. Connect AC Power Cord to the projector and turn it on.

6. Reset Lamp Replace Counter (refer to the section “Lamp Replace Counter” below).

[Do not reset Lamp Replace Counter when Projection Lamp is not replaced]

LAMP REPLACE COUNTER

[Be sure to reset Lamp Replace Counter when Lamp Assembly is replaced. When Lamp Replace Counter is reset, LAMP REPLACE Indicator stops lighting.]1. Turn projector on, press MENU button and ON-SCREEN MENU will appear. Press POINT LEFT/RIGHT button(s) to move a red frame pointer to SETTING Menu icon.

2. Press POINT DOWN button to move a red frame pointer to “Lamp counter reset” and then press SET button. The message "Lamp replace counter reset?" is displayed. Move the pointer to [Yes] and then press SET button.

3. Another confirmation dialog box appears and select [Yes] to reset Lamp Replace Counter.

(Do not reset Lamp Replace Counter except after Projection Lamp is replaced.)

2. Press POINT DOWN button to move a red frame pointer to “Lamp counter reset” and then press SET button. The message "Lamp replace counter reset?" is displayed. Move the pointer to [Yes] and then press SET button.

3. Another confirmation dialog box appears and select [Yes] to reset Lamp Replace Counter.

(Do not reset Lamp Replace Counter except after Projection Lamp is replaced.)

FUSE FOR CIRCUIT PROTECTION

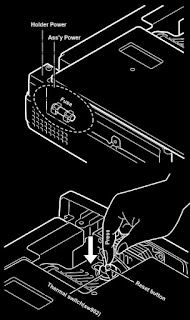

The fuse is located on the ass'y-power. When either the LAMP indicator or the READY indicator is not illuminated, fuse may be opened. Check the fuse as following steps.

Remove the ass'y-power following to “Mechanical Disassemblies”.

2. Remove the fuse from fuse holder.

3. Check the resistance of fuse by using the tester.

2. Remove the fuse from fuse holder.

3. Check the resistance of fuse by using the tester.

To install the fuse, take reversed step in the above.

The temperature monitor system.

The temperature monitor system is provided to prevent damage of component parts inside the projector from overheat. Two protection systems are provided.

Temperature monitor -1 :

When this function operates, warning-temperature-indicator flashes. And cooling fan continues operating until it becomes a normal temperature. If it continue to flush and flash does not stopped, disconnect the AC cord and investigate the cause of overheating.

When this function operates, warning-temperature-indicator flashes. And cooling fan continues operating until it becomes a normal temperature. If it continue to flush and flash does not stopped, disconnect the AC cord and investigate the cause of overheating.

Temperature monitor -2 : (thermal switch SW902)

This function (thermal switch SW902) will not operate, while the temperature monitor -1 is operating normally. If it has operated, it needs to be reset manually. Disconnect the AC cord first and investigate the cause of overheating. After servicing, reset the thermal switch (SW902) as shown.

This function (thermal switch SW902) will not operate, while the temperature monitor -1 is operating normally. If it has operated, it needs to be reset manually. Disconnect the AC cord first and investigate the cause of overheating. After servicing, reset the thermal switch (SW902) as shown.

SERVICE ADJUSTMENT

To enter service mode

To enter service mode press the "MENU" and "IMAGE" buttons on the projector simultaneously and hold for 2 seconds. As shown in a figure, a service mode display appears on a screen.

To enter service mode press the "MENU" and "IMAGE" buttons on the projector simultaneously and hold for 2 seconds. As shown in a figure, a service mode display appears on a screen.

Adjust service data using the following control buttons.

1. "POINT UP" ------- An item number increases.

2. "POINT DOWN" -- An item number decreases.

1. "POINT UP" ------- An item number increases.

2. "POINT DOWN" -- An item number decreases.

3. "POINT RIGHT" -- "VOLUME+" | An adjustment value increases. |

4. "POINT LEFT" ---- "VOLUME - " | An adjustment value decreases. |

Press the "POWER on/off" button only once on the projector or remote control unit to quit the service mode.

SERVICE MODE ADJUSTMENT MENU

[Other adjustment items are not related to service and a maintenance. Don't press the VOLUME (+) and (-) buttons at the time of those adjustment items. Otherwise it may cause loss of product safety]

Fan driving voltage adjustment1. Enter the service mode.

Set the item no. to [50] by pressing the Point up or down button.

Set the data value to [1] by pressing the Volume + or – button.

2. Set the item no. to [67]. Set the data value to [1].

3. Adjust the voltages of TP66A to 8.4 ± 0.1 V-DC by the VR5601.

4. Set the item no. to [50]. Set the data value to [0].

5. Set the item no. to [67]. Set the data value to [1].NRS adjustment

Signal center DC adjustment.

Enter the service mode.

Adjust each values of below test point to be minimum amplitude by volume + or – buttons.Contrast adjustment

Schematic