It makes sense to avoid exposure to electrical shock. While some sources are expected to have a possible dangerous impact, others of quite high potential are of limited current and are sometimes held in less regard.

Always respect voltages. While some may not be dangerous in themselves, they can cause unexpected reactions that are best avoided.

BOM identification

It should be noted that on the European Service website, “Alternative BOM” is referred to as “Design variant”.

The third digit in the serial number (example: KX2B0835000001) indicates the number of the alternative B.O.M. (Bill Of Materials) that has been used for producing the specific AV set. In general, it is possible that the same AV model on the market is produced with e.g. two different types of display, coming from two different suppliers. This will then result in sets which have the same CTN (Commercial Type Number; e.g. MCM394/12) but which have a different B.O.M. number.

Also, it is possible that same model on the market is produced with two production centers, however their parts list is the same. In such case, no alternative B.O.M. will be created.

By looking at the third digit of the serial number, one can identify which B.O.M. is used for the set he is working with. If the third digit of the serial number contains the number “1” (example: KX1B033500001), then the set has been manufactured according to B.O.M. number 1. If the third digit is a “2” (example: KX2B0335000001), then the set has been produced according to B.O.M. no. 2. This is important for ordering the correct spare parts. For the third digit, the numbers 1...9 and the characters A...Z can be used, so in total: 9 plus 26= 35 different B.O.M.s can be indicated by the third digit of the serial number.

Identification:

The bottom line of a type plate gives a 14-digit serial number. Digits 1 and 2 refer to the production centre (e.g. LM is Arts), digit 3 refers to the B.O.M. code, digit 4 refers to the Service version change code, digits 5 and 6 refer to the production year, and digits 7 and 8 refer to production week (in Example below it is 2008 week 50). The 6 last digits contain the serial number.

Module Level Repair (MLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide if the board has to be exchanged or if it should be repaired on component level. If your repair procedure says the board should be exchanged completely, do not solder on the defective board. Otherwise, it cannot be returned to the O.E.M. supplier for back charging.

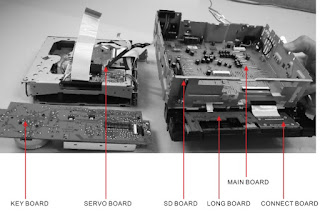

PCB locations

Disassembly procedure

Software check and upgrade

Copy the file “MCU.BIN” into a USB stick.

2. Power ON the device, and plug the USB stick into USB socket. After the device read the content in the USB, the LCD will show a upgrade menu, and enter into the upgrading status.

3. The LCD will appear a number (changed from 20 to 0), and when arrived the number 0, then appear a processing bar, which mean the device enters upgrading status.

4. in step 3, if want to enter into the upgrading status quickly, press the key OK to confirm, the processing bar will appear immediately.

6. When software upgrade is complete, the device will power off automatically.

Check servo software version

Copy the file “ROM.BIN” into USB stick (note to delete the file “MCU.BIN”)

2. Power ON the device, and plug the USB stick into USB socket. After the device read the content in the USB, the LCD will show a upgrade menu, and enter into the upgrading status.

3. The LCD will appear a number (changed from 20 to 0), and when arrived the number 0, then appear a processing bar, which means the device enters upgrading status.

4, press the key OK to confirm, the processing bar will appear immediately.

5. Disconnect the USB stick.

6. When software upgrade complete, the device will change to disc mode automatically.

When the device is power ON at the first time, in USB or SD or Disc mode, press the key in turn:

Stop > Up > Down > Left > Right

The LCD will display the service software, MCU, TFT version number.

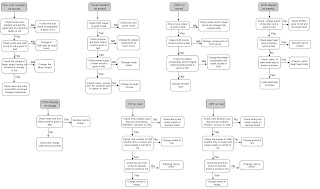

Malfunction chart

Wiring diagram

Circuit diagram