SERVICE [FACTORY MODE]

- Enter the factory menu (can use the IR) and press the remote key [◄V-] to “0’, press mute remote key, then press 9,7,3,5 remote key.

- Press [►] key to enter the sub-menu and press MENU key to return the main-menu.

ADJUSTMENTS

Adjust the temperature in CMP, VGA, AV.Make sure the picture mode is set to “Stand”, the “Picture àBlack expand” on the user Menu is set to “OFF”. “Other àFlesh Tone & Adaptive Luma Control ” on

the factory Menu is set to “OFF”. After Alignment, the entire item will change to “ON”

ADC ADJUST

- For CMP input, the test signal is 576i/50Hz,100%, 8 steps colour bar. Select the “Balance àRGB Calibrate” on the factory Menu, then press “à”, ADC adjust is finished after “OK” is displayed

- For VGA input, the test signal is 1024×768/60Hz white/black grid. Select the “Balance à RGB Calibrate” on the factory Menu, then press “à”, ADC adjust is finished after “OK” is displayed.

VGA ADJUST

- For VGA input, the test signal is 1024×768/60Hz 16 steps gray bar. Set the “Balance àTone” on factory menu to “Normal”:

- For the third step form the white bar, Adjust the value of White R,White G,White B, until the color temperature is x=280±5, y=290±5 Y > 220nit

- For the second step form the black bar, Adjust the value of GrayR, Gray G, Gray B, until the color temperature is x=280±5, y=290±5 Y < 25nit

- Repeat, until all is ok

- Adjust the value of Black level.

AV ADJUST

- For AV3 input, the test signal is PAL - 8 steps gray bar. Set the “Balance àTone” on factory menu to “Normal”:

- For the third step form the white bar, Adjust the value of White R, White G, White B, until the color temperature is x=280±5 y=290±5 Y > 220nit

- For the second step form the black bar, Adjust the value of GrayR, Gray G, Gray B, until the color temperature is x=280±5 y=290±5 Y < 25nit R

- Repeat A&B, until all is ok

- Adjust the value of Black level.

CMP ADJUST

- For CMP input, the test signal is 576i/50Hz-16 steps gray bar. Set the “Balance à Tone” on factory menu to “Normal”:

- For the third step form the white bar, Adjust the value of White R, White G, White B, until the color temperature is x=280±5 y=290±5 Y > 220nit

- For the second step form the black bar, Adjust the value of GrayR, Gray G, Gray B, until the color temperature is x=280±5 y=290±5 Y < 25nit

- Repeat until all is ok

- Adjust the value of Black level

Prepare MTKTOOL UPDATE, update board, serial line.

- Connect PC, update board, and J3 on the main board with serial line

- Provide the STB +5V for main board

- Open “MtkTool.exe” in MTK TOOL program, and set the parameter as below picture.

- Press “Browse” for selecting the SW.

- Press “Upgrade” to download the SW. It will be OK when it shows “100%”

- After downloading SW, it will be long time for Initializing EEPROM.

Preparative is same with above.

- Set SYSTEM > Factory Key on factory MENU to OFF. Connect the device as below picture.

- Update the SW follow solution- (3), (4), (5), (6)

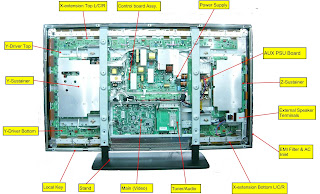

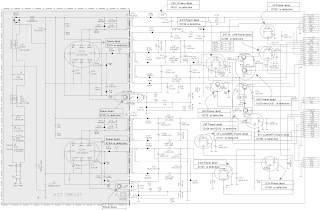

MAIN POWER SUPPLY SCHEMATIC {Click on Pictures to Zoom In}