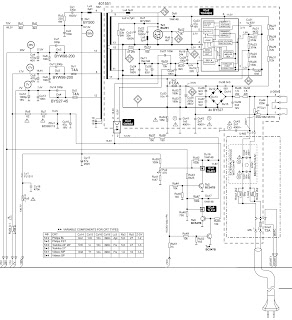

Power Supply Schematic [STRF6654LF57]

Video Output Schematic [TDA 6103Q/N3]

CLICK ON SCHEMATICS TO ZOOM IN

FACTORY SETTINGS- Self-check is used to automatically check the bus lines and hexadecimal code of the TV set.

- To enter Self-Check mode. Press the down (-/v) button on the customer controls at the front of the TV set, at the same time pressing the STATUS button on the remote control.

- To exit Self Check, switch off the TV set at the power button.

Self-Check should only be used when refurbishing the TV set and not during normal repair work.