↧

Electrical Schematic - NIDEK NUVO-8 - Oxygen Concentrator

↧

PANASONIC LASER FAX - DX2000 - HOW INSTALL MEMORY CARD - HOW TO INSTALL TONER CARTRIDGE

MEMORY CARD INSTALLATION

Before installing, make sure that there is no document file(s) stored in the memory. You may confirm by printing out a File List (see page 139 of the User's Guide). When the memory card is installed, the machine will initialize the document memory, all contents stored in the document memory at that time will be lost.

- Turn the Power Switch to the "O" (OFF) position located in the rear of the machine.

- Open the ADF Door.

- Remove a Screw.

- Remove the Memory Card Cover.

- Insert the Memory Card(s) gently into the card slot with the Panasonic logo facing to the rear.

- Reinstall the Memory Card Cover and the Screw to secure the Cover.

- Turn the Power Switch to the "I" (ON) position. Print out the Fax Parameter List (see page 180 of the User's Guide) and confirm that the memory size on Fax Parameter No. 099.

2. The memory size on Fax Parameter No. 099 is only shown for the Flash Memory Card.

- Unpack the Toner Cartridge and rock it back and forth as shown for 5 or 6 times to even the toner inside.

- Remove the protective seal. Note: Pull on the seal slowly and straight out.

- Push the Release Button to open the Printer Cover.

- Align the arrow and the projection on both sides as shown and insert the Toner Cartridge into the machine.

- Close the Printer Cover firmly.

↧

↧

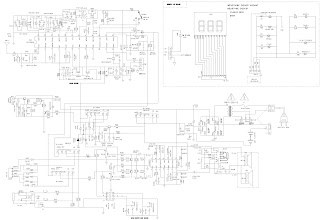

LCT 20KX01LST - AKIRA LCD TV - BACK-LIGHT INVERTER - POWER ADAPTER - SCHEMATIC [Circuit Diagram]

↧

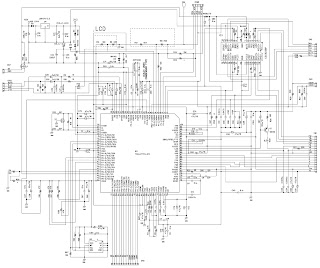

CT29FS9AN - AKIRA CRT BASED TV - SCHEMATIC [Full] - KA5Q12XRF – M52797SP – TDA93xx/N2 – TDA4863 – TDA8944 – TDA9859 – TDA9874

↧

AKIRA - CT29FS9AN – AKIRA CT21FS9 – SERVICE ADJUSTMENTS - FULL

SERVICE ADJUSTMENTS

- The main power is 90~260V/50/60Hz. Be careful when you debug and equip.

- Don’t short any two soldering points, which should not be shorted and don’t touch any component, which should not be touched.

- Pull out plug before any adjustment to chassis.

- For safety reasons, all components equipped or replaced should be identical with BOM.

- Must be warm up for 30 minutes or more and degauss CRT thoroughly with demagnetizer before alignment.

- The data of EEPROM must be stored before the adjustment for main chassis.

Small “-” screwdriver.

Screwdriver without inductance.

Pattern Generator.

DC regulator power supply.

Digital Voltmeter.

Sweep signal generator.

20MHz 2-channel Oscilloscope.

Power adjustmentConnect a 100W bulb cross C616. Then connect AC 220V power to CN601. If the bulb light, the voltage is prescriptive, and there is no unconventionality, then the power is OK, else be repaired.

FACTORY MODE [Service Mode]

Click on pictures to zoom

Vertical size and pin cushion adjustment (KEY 2)

- Receive 50HZ cross hatch pattern. Set TV standard status, adjust 5VSL to obtain half of the cross hatch, adjust 5SCL to obtain picture’s vertical pin cushion a good status, adjust 5VSH to obtain picture’s vertical center at the center of CRT screen in factory mode.

- Receive 50HZ monoscope pattern. Set TV standard status,. Adjust 5VAM to obtain picture’s vertical redisplay ratio more than 90% in factory mode.

- Receive 60HZ cross hatch pattern. Set TV standard status. Adjust 6VSL to obtain half of the cross hatch, adjust 6SCL to obtain picture’s vertical pin cushion a good status. Adjust 6VSH to obtain picture’s vertical center at the center of CRT screen in factory mode.

- Receive 60HZ monoscope pattern. Set TV standard status. Adjust 6VAM to obtain picture’s vertical redisplay ratio more than 90% in factory mode.

- If necessary, adjust Horizontal Center and EW again.

- Receive 50HZ RGB or YUV cross hatch pattern. Set TV standard status. Adjust 5RGH to obtain picture’s vertical center at the center of CRT screen in factory mode. (OPTION).

- Receive 60HZ RGB or YUV cross hatch pattern. Set TV standard status. Adjust 6RGH to obtain picture’s vertical center at the center of CRT screen in factory. (OPTION).

- Receive 50HZ monoscope PATTERN. Set TV standard status. Adjust 5HSH to obtain horizontal center at the center of CRT screen.

- Receive 50HZ cross hatch pattern. Set TV standard status. Adjust 5EWW, 5PWW, 5UCR, 5LCR, 5PAR, 5BOW, 5EWT to obtain picture’s Horizontal redisplay ratio more than 90% in factory mode.

- Receive 60HZ monoscope PATTERN. Set TV standard status. Adjust 6HSH to obtain horizontal center at the center of CRT screen.

- Receive 60HZ cross hatch pattern. Set TV standard status. Adjust 6EWW, 6PWW, 6URC, 6LCR, 6BOW, 6EWT to obtain picture’s Horizontal redisplay ratio more than 90% in factory mode.

- Menu OSD position adjustment. Received 50/60Hz cross hatch pattern. Set TV standard status. Press KEY 2 in factory mode, adjust 5VOF /6VOF and HOF item, to obtain menu OSD at the center of CRT screen.

- LOGO position adjustment. Receive 50/60Hz cross hatch pattern. Set TV standard status. Press KEY 7 in factory mode, adjust XMIN, XMAX, YMIN, and YMAX item, to obtain LAGO at the center up to 1/3 of CRT screen.

- TELETEXT OSD position adjust. Received 50/60HZ TELETEXT signal. Set TV standard status. Press KEY 7 in factory in factory mode, adjust TXMI and 5TYM/6TYM item, to obtain INDEX at the center of CRT screen.

- Normally, 5P60 can auto adjust white balance, but for some CRT need to adjust white balance carefully by hand. Set BRIGHTNESS and

- CONTRAST at normal status, receive GREY SCAL and entering factory mode press KEY 3, set WPR at 31, adjust WPG and WPR to obtain white balance.

When in repairing, we can replace E2PROM by other empty or not empty E2PROM, but you must initialize E2PROM to avoid unknown things.

- Press remote control KEY CLOCK, P.M. in turn to entering factory mode.

- Press remote control KEY 8 to entering INIT menu, then press key PROG +, you can see “INIT BUSY” waiting for about 5 seconds till “BUSY” disappeared, then POWER OFF and ON by main power E2PROM initialization in completed.

- Setting the data in E2PROM. When in manufacturing, first you read the data from an good E2PROM 24C08, then WRITE to other E2PROM 24C08.

This appendix shows information about service items that are available. The table list all possible available service items with its.

↧

↧

LG RE39NZ43 – LG RL39NZ43 RPTV - POWER SUPPLY SCHEMATIC [Circuit Diagram] - STR 6351 – STR F6658B

↧

RPTV - LG RE39NZ43 – LG RL39NZ43 – Convergence – R G B Output - Power - Schematic Diagram [Circuit Diagram] - (STK 392-120 – TDA6111Q)

↧

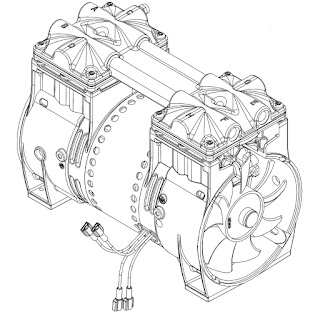

RIETSCHLE THOMAS - 2660CE37-807 & 2660CGHI42-807 - Compressor - TROUBLESHOOTING - SERVICING

EXPLODED VIEW

CLICK ON THE PICTURES TO ZOOM

TROUBLESHOOTING CHART

How to Service the Head, Valve Plate Assembly and Connecting Rod and Bearing Assembly.

- Disconnect the power.

- Disconnect all air lines and remove compressor from the enclosure.

- Remove all screws (1) that fasten the head (2) to the compressor housing.

- Carefully separate the head from the compressor body.

- Carefully separate the valve plate assemblies (4) from the heads.

- Remove the head gasket O-rings (3) and replace.

- Turn the valve plates over and replace the valve plate gasket O-rings (5).

Removing the Flapper Valves.

- If you are replacing a flapper valve on the top side of the valve plate (side facing the head), remove the flapper valve screw (1) with a 1/4" hex socket, lift off the valve keeper strip (2), lift off the valve restraint (3), and lift off the flapper valve (4).

- Remove any debris from the valve plate with a damp, lint free cloth. (Soaps and detergents should not be used due to the potential for corrosion from soap residue.)

- Place the valve plate on the compressor housing and orient it as illustrated. Note the orientation of the valve ports.

- Orient a new flapper valve (1) over Port 1. Observe the location of the notches (2) at the end of the flapper valve.

- Place a valve restraint (3) over the flapper valve.

- Place a valve keeper strip (4) over the valve restraint observing that the word “UP” is facing you and oriented as shown in the illustration.

- Line up the screw holes in all of the valve components and insert the flapper valve screw (5) into the valve plate.

- Make sure the flapper valve is centered over the port and that all of the other components line up with the flapper valve.

- Do not over tighten the flapper valve screw or it will shear off in the valve plate.

- Tighten the flapper valve screw to 18 inch pounds, using a torque wrench with a 1/4" hex socket attachment.

Contd by next post:

↧

FLAPPER VALVE REPLACEMENT - RIETSCHLE THOMAS 2660CE37 - COMPRESSOR

CONTN:

If you are replacing a flapper valve on the bottom side of the valve plate (side facing the compressor housing), remove the flapper valve screw (1) with a 1/4" hex socket, lift off the valve keeper strip (2), clean any debris with a soft, damp cloth. Turn the compressor head upside down and place the valve plate on the compressor head and orient it as illustrated. Note the position of the valve ports and the location of the power leads on the compressor housing.

Orient a flapper valve (1) over Port 2. Observe the location of the notches (2) at the end of the flapper valve.

- Place a valve keeper strip (3) over the flapper valve, observing that the word “UP” is facing you, not the valve plate, and oriented as shown in the illustration.

- Line up the screw holes in all of the valve components and insert the flapper valve screw (4) into the valve plate.

- Make sure the flapper valve is centered over the Port and that the valve keeper strip lines up with the flapper valve.

- Do not over tighten the flapper valve screw or it will shear off in the valve plate.

- Tighten the flapper valve screw to 18 inch pounds, using a torque wrench with a 1/4" hex socket attachment.

- Carefully remove the fan by pulling it straight off the motor shaft. Do not pull the fan blades.

- Turn the motor shaft to align the eccentric set screw with its access hole and use an Allen wrench to loosen the eccentric set screw (see illustration for location of access hole).

- Make sure the connecting rod is at "Top Dead Center". Slide the connecting rod assembly straight off the shaft through the opening in the Housing.

Rebuilding Connecting Rod Assemblies. If you are rebuilding the connecting rod assembly using component parts, follow this procedure:

When replacing the piston cup (4), be sure to replace the sleeve (1) at the same time. Place the con rod shaft in a fixture before attempting to remove the retainer screw. Heat will help to dissolve the lactate bond.

- Remove the retainer screw (2) from the cup retainer.

- Remove the retainer (3) from the connecting rod.

- Remove the cup (4) and discard.

- Place the new piston cup (4) on the connecting rod.

- Place a piston cup retainer (3) on the cup/connecting rod making sure the boss of the retainer is seated in the pilot of the rod.

- Insert the retainer screw (2) into the connecting rod (5) and tighten to 95-105 inch-pounds.

Assembly of the Connecting Rod to the Compressor.

- Line up eccentric set screw with flat on shaft. Slide connecting rod assembly over shaft through front of housing with eccentric toward end of shaft. Push connecting rod assembly tight against housing bearing.

- Rotate eccentric to line up setscrew with access hole in bottom of housing. Tighten screw to 125 in. lbs. Make sure the eccentric set screw is seated perpendicular on the shaft flat.

After the connecting rod assembly and eccentric are correctly assembled, you can assemble the valve plates and head to the compressor.

To prevent damage to the compressor, never apply any sealant or lubrication to the O-rings.

- Insert a new head gasket O-ring into the groove located on the top of the valve plate.

- Insert the valve plate gasket O-ring into the O ring groove located on the bottom of the valve plate.

- Position the compressor housing as shown in the illustration. Notice the orientation of the power leads.

- Observe the orientation of the valve plate assemblies. The tabs on the valve plate indicate exhaust side. Place them on the compressor housing as shown.

Ensure that O-Rings are fully assembled in grooves and not pinched.

Make sure that the connecting rod sleeves are seated against the compressor housing.

- Place the head on the valve plate assemblies observing the position of the air intake and exhaust ports.

- Insert the head screws and finger tighten each screw until it is snug. Use a Torx® T-25 driver to tighten each head screw to 55 inchpounds, in the sequence shown.

Servicing the Fan

If one or both of the fans break, use the following procedure:

- Carefully remove the fan by pulling it straight off the motor shaft.

- Align the flat on the motor shaft with the flat on the fan and slide the fan back onto the motor shaft, making sure the fan clip (1) faces as shown.

↧

↧

PHILCO PCA 230 - AUTO RADIO - SCHEMATIC DIAGRAM [Circuit Diagram] - TDA 8264 – KIA 4558 – TDA 7313

↧

UN32D5500 - UN40D5500 - SAMSUNG LED LCD TV - HOW TO ENTER SERVICE MODE - HOW TO UPGRADE SOFTWARE

TO ENTER SERVICE MODE

SOFTWARE & MICOM UPGRADE

- If you do not have Factory remote – control; [Power OFF àMUTE à 1 à 8 à 2 à Power ON]

- If you do not have Factory remote – control; [INFO à factory]

SOFTWARE UPGRADE

- Downloading the latest firmware from samsung.com to a USB memory device can perform software Upgrade.

- Current Version - the software already installed in the TV.

- Software is represented as ‘Year/Month/Day_Version’.

TO CHECK SOFTWARE VERSION

- Use the main menu

- Click the “menu” key in remote controller.

- Select Support menu.

- Locate the menu cursor “Software Upgrade” menu.

- Click the “info” key.

- Check the Main SW and Micom version.

Access the factory mode.

CLICK ON THE PICTURES TO ZOOM. Clickßat the top of the browser, to come back.

SOFTWARE & MICOM UPGRADE

Insert a USB drive containing the firmware upgrade downloaded from samsung.com into the TV. Be careful to not disconnect the power or remove the USB drive while upgrades are being applied. The TV will turn off and turn on automatically after completing the firmware upgrade. Please check the firmware version after the upgrades are complete (the new version will have a higher number than the older version). When software is upgraded, video and audio settings you have When software is upgraded, video and audio settings you have you write down your settings so that you can easily reset them after the upgrade.

MAIN SOFTWARE UPGRADE

- Store the sw program named “T-MST5IBRC” in USB memory stick.

- Connect the USB.

- Connect TV and online line.

- Select. Support menu.

- Locate the menu cursor “Software Upgrade menu.”

- Click the “ENTER” key.

- You can upgrade by USB or Online.

- Click the “ENTER” key.

- Wait for upgrade complete and check the SW version.

SUB-MICOM UPGRADE

You can upgrade sub micom in factory mode without DDC program. But it takes long time about 5 minutes.- Access the Factory mode.

- Select the “SVC” menu and locate the cursor “MICOM UPGRADE” menu.

- Click the “ENTER” key.

- Click the “right” key.

- Wait for upgrade complete and check the Micom version.

↧

HOW TO DISASSEMBELE - SAMSUNG UN-32D5500 - UN40D5500 - LED LCD TV

DISASSEMBLY PROCEDURE

Remove 4 screws from the stand. Remove stand.

Remove the screws of Rear-cover.

Lift up the Rear-cover.

Remove the Left and Right Speaker.

Remove the 6 screws of Main Board and 5 screws of IP Board.

Remove the 2 screws of Stand Link Cover.

Remove the 4 screws of Stand Link.

Lift up the Stand Link.

Detach the Front Hook.

Lift up the Panel

CLICK ON THE PICTURES TO ZOOM. Click ß at the top of the browser to come back

How to disassembly Function & IR ASSY

Check the 2 Function Clips.

Remove the 2 Function Clips.

Heat the Function Assy by Heat Gun and Lift up the Function Assy.

↧

PHILCO PH91 - SCHEMATIC DIAGRAM [Circuit Diagram] - ICs used - CSC2308FN - UTC8227 – CSC9258P - TC94A77FG-612

↧

↧

LG LM U1060 – LMS U1060 – 3-CD CHANGER - SMPS POWER SUPPLY SCHEMATIC [Circuit Diagram] - STR X6759N / STR W6754 - STR A6252

↧

POWER AMP SCHEMATIC - LG LM U1060 – LMS U1060 – 3-CD CHANGER - [HT 1000x4]

↧

SONY - HCD D670AV – HCD N555AV - DISASSEMBLY PROCEDURE

↧

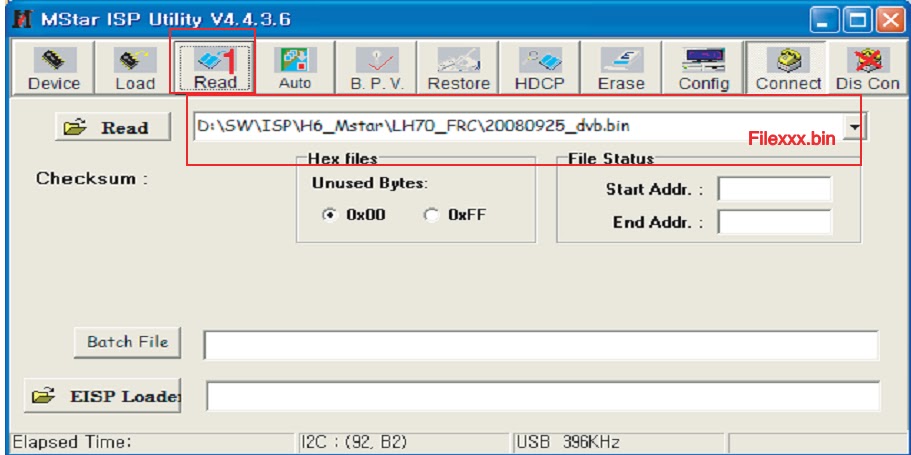

LG 26LD330 - LCD TV - PCB Ass'y Adjustment - Software (Firmware) Update Procedure.

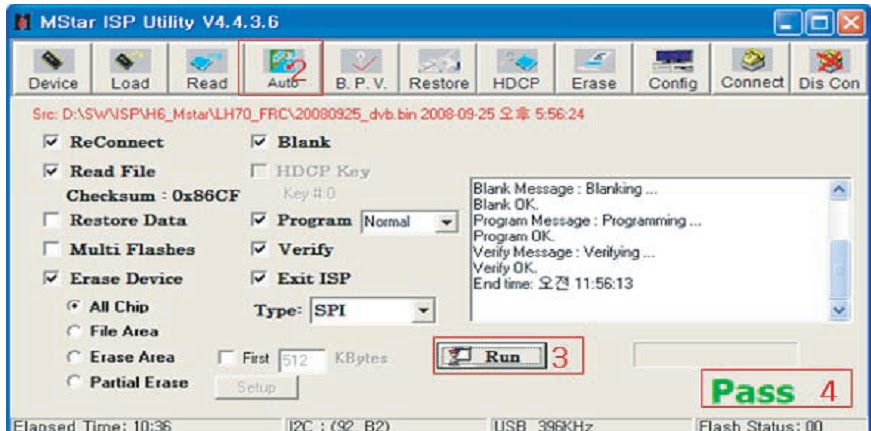

Mstar Main S/W Program Download

- Connect the download jig to D-sub(RGB) jack.

- Execute ‘ISP Tool’ program, the main window (Mstar ISP utility Vx.x.x) will be opened.

- Click the “Connect” button and confirm “Dialog Box”

- Click the “Config.” button and Change speed I2C Speed setting : 350 Khz ~ 400 Khz.

- Read and write bin file. Click “(1)Read” tab, and then load download file (XXXX.bin) by clicking “Read”.

- Click “(2) Auto” tab and set as below.

- Click “(3) Run”.

- After downloading, you can see the “(4) Pass” message.

USING MEMORY STICK

- Insert the USB memory stick to the USB port.

- Automatically detect the SW Version. à S/W download process is executed automatically.

- Show the message “Copy the file from the Memory.

- After Finished the Download, Automatically DC Off àOn.

- Check the update SW Version.

↧

↧

TDA 7495 - AUDIO OUTPUT SCHEMATIC [Circuit Diagram] - Audiovox FPE 3000 LCD TV

↧

AUDIOVOX FPE 3000 LCD TV - TROUBLESHOOTING - Troubleshooting Guide

COMMON FAULTS AND CHECKS

Picture is out of focus or jumping | * Bad status in signal receiving * Maybe broadcast signal itself is not good * Check if the outdoor antenna is disconnected. * Check if the antenna is correctly oriented. |

Fringe in picture | * Check if the antenna is correctly oriented. * Maybe there is electric wave reflected from hilltop or building. |

Picture is interfered by stripe shaped bright spots | * Possibly due to interference from automobile, train, high voltage transmission line, neon lamp etc. * Maybe there is interference between antenna and power supply line. Please try to separate them in a longer distance. |

Appear streaks or light color on the screen | * Check if interfered by other equipment and if interfered possibly by the equipment like transmitting antenna, non Professional radio station and cellular phone. |

Unable to switch the power on | * Check to see if the power plug has been inserted properly into the socket |

No picture and sound | * Check to see if the power supply of liquid crystal TV has been switched on. (as can be indicated by the red LED at the front of the TV set) * See if it’s receiving the signal that is transmitted from other source than the station * Check if it’s connected to the wrong terminal or if the input mode is correct. * Check if the signal cable connection between video frequency source and the liquid crystal TV set is correct. |

Deterioration of color phase or color tone | Check if all the picture setups have been corrected. |

Screen position or size is not proper | Check is the screen position and size is correctly set up |

Picture color changed or colorless | Check the “Component” or”RGB”settings of the liquid crystal TV set and make proper adjustment according to the signal types. |

Picture too bright and there is distortion in the brightest area | * Check if the contrast setting is too high. * Possibly the output quality of DVD broadcaster is set too high. * It maybe also due to improper terminal connection of the video frequency signal in a certain position of the system. |

Picture is whitish or too bright in the darkest area of the picture | * Check if the setting for the brightness is too high * Possibly the brightness grade of DVD player (broadcaster) is set too high. |

No picture or signal produced from the displayer if “XXX in search” appears. | * Check if the cable is disconnected. * Check if it’s connected to the proper terminal or if the input mode is correct. |

Appears an indication “outside the receivable scope” | Check if the TV set can receive input signal. The signal is not correctly identified and VGA format is beyond the specified scope. |

Remote control cannot work properly | * Check if the batteries are installed in the reverse order. * Check if the battery is effective. * Check the distance or angle from the monitor. * Check if there is any obstruct between the remote control and the TV set. * Check if the remote control signal- receiving window is exposed to strong fluorescence. |

No picture and sound, but only hash. | Check if the antenna cable is correctly connected, or if it has received the video signal correctly. |

Blur picture | * Check if the antenna cable is correctly connected. * Of if it has received the right video signal. |

No sound | * Check if the “mute” audio frequency setting is selected. * Check if the sound volume is set to minimum. * Make sure the earphone is not connected. * Check if the cable connection is loose. |

When playing VHS picture search tape, there are lines at the top or bottom of the picture. | When being played or in pause VHS picture search tape sometimes can’t provide stable picture, which may lead to incorrect display of the liquid crystal TVIn this case please press “auto” key on the remote control so as to enable the liquid crystal TV set to recheck the signal and then to display correct picture signal |

CLICK ON PICTURES TO ZOOM. Click ß] at top left of the browser, to come back.

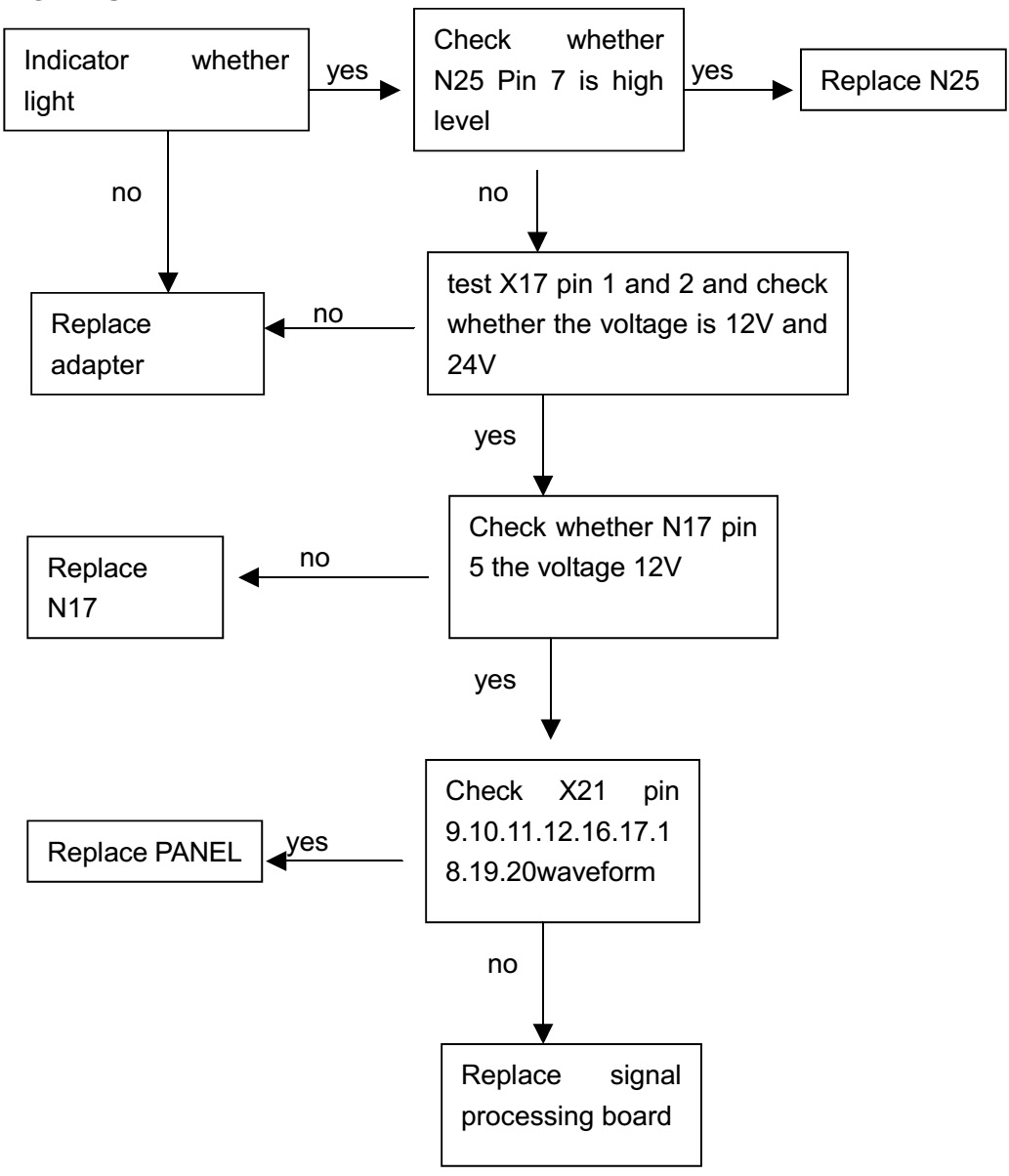

NO PICTURE [HAVE RASTER]

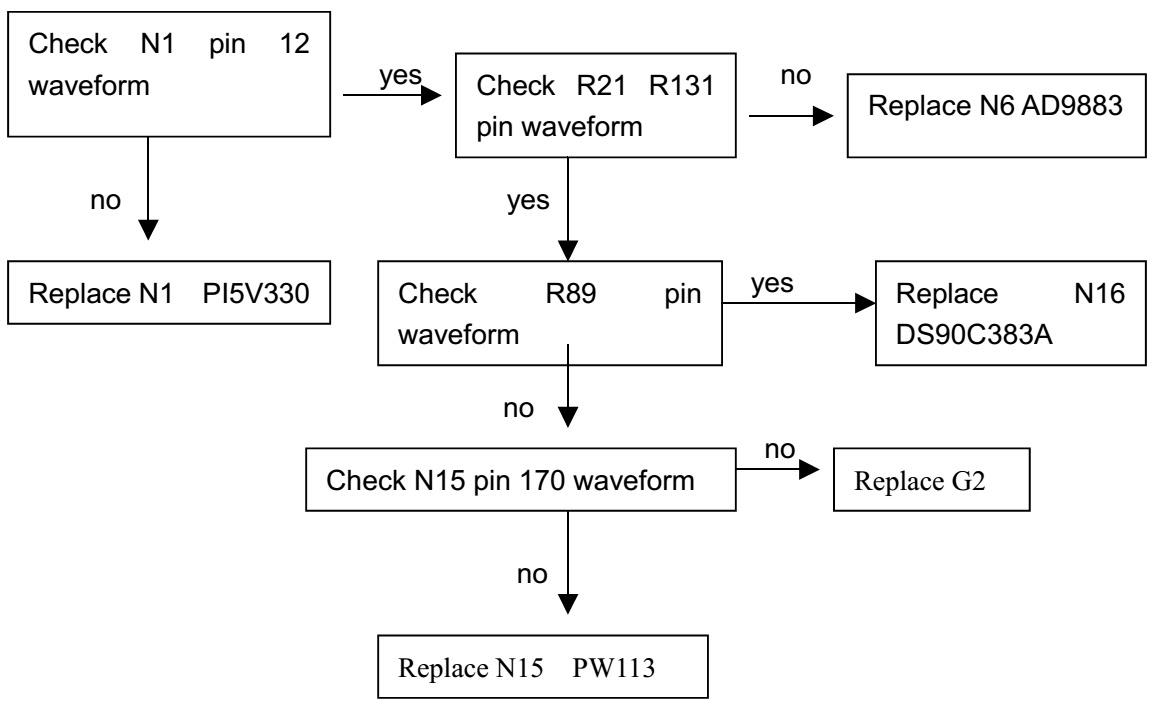

S-VIDEO & YCBCR - NO PICTURE

NO PICTURE - TV

NO SOUND

↧

HOW TO UPGRADE SOFTWARE [Firmware] - AUDIOVOX FPE3000 LCD TV

FIRMWARE UPDATE PROCEDURE

- Select a serial connection wire and a VGA connection wire and then connect them by means of a patch panel;

- Use a serial wire to connect the PC to the patch panel and set TV set to off state;

- Open the software upgrade file holder and double click.

The following interfaces will show up after running the program:

Based on the computer features, setup the serial port (COM Port). Select corresponding serial port (if it’s unable to FLASH WRITE, change to another port). Baud is selected to be 115200. Then select Reset Target After Download. Click FLASH pushbutton, it’s ready to run. For other settings.

Switch on TV set the FLASH write program begins to run;

After FLASH write is over, push button “cancel” will become flash. Then shut the main power supply and it’s OK just switch it on again.

Note:Do not shut the power off or turn the TV set on during the FLASH write. Otherwise it may lead to no way for flash to rewrite.

↧