↧

PANASONIC TC14A8 - TC14A9 - TC20A8 - TC20A9 - SMPS [Power Supply Regulator] - Schematic diagram

↧

PANASONIC TC14RM15L - TC21FX32L - SCHEMATIC DIAGRAM [Circuit Diagram]

↧

↧

LCD PROJECTOR - PANASONIC PT LB60NTU - SELF CHECK MODE – FLICKER ADJUSTMENT – EXIT OPTION

EXIT OPTION

This projector has EXT OPTION in addition to standard on-screen menus. There are SELF CHECK and TEST PATTERN for service, etc.

Procedure to enter EXT OPTION

- Press "MENU" button on the main unit or remote control unit to display "MENU" screen, then select "OPTION" and press "ENTER" button.

- Select "INPUT GUIDE" on "OPTION" menu and press "ENTER" button 3 seconds or longer. MENU àOPTION àINPUT GUIDE.

EXIT OPTION MENU & FUNCTIONS

FREEZE MESSAGESwitching ON/OFF "FREEZE" on-screen display. ANGLE RESET

Switching ON/OFF "Real-time Keystone" reference level setting

Note: Normally, do not select. (Angle reset data will be rewritten.)

FAN FULL MODE

Setting the cooling fan motor rotation speed. Switching ON "FAN FULL MODE", the rotation level of the fan becomes high-speed rotation (fixed). Moreover, when "FAN FULL MODE" is ON, changing "HIGHLAND" in OPTION becomes impossible (setting "FAN FULL MODE" is given priority more than "HIGHLAND").

AUTOSETUP

Setting AUTO SETUP mode:

STANDARD: To set the normal mode (the dot clock is adjusted strictly))

SPECIAL: To set the special mode (the dot clock is adjusted roughly)

Note: Do not change the initial setting (STANDARD).

SYNC: Setting SYNC processing mode

STANDARD: To set the normal mode

SPECIAL: To set the special mode (noise reduction mode)

Note: Do not change the setting when it is possible to receive normally. Change the setting only when the image is not displayed normally because of the sync signal noise of connected equipment.

VGA60/480p: AUTO: Switching RGB of VGA60 and 480p automatically.

VGA60: Inputting signals in 59.9Hz / VGA480

480p: Inputting signals in RGB of 480p

SELF CHECK

To enter the self-check mode

TEST PATTERN

To display test patterns

FLICKER ADJUST

To enter the flicker adjustment mode

HPLL

When non-standard signal of VIDEO/S-VIDEO is inputted (VTR, VHD, etc.), horizontal synchronization might be disordered according to connected equipment. In this case, set HPLL to OFF.

CANCELLING THE 'EXIT' OPTION

Press "MENU" button on the main unit or remote control unit.

Self-Check Mode: This mode is used to narrow down the location of the failure.

Procedure to enter the self-check mode

Select "SELF CHECK" on "EXT OPTION" menu and press "ENTER" button on the main unit or remote control unit.

SELF CHECK DISPLAY AND CONTENTS

CLICK ON THE TABLES TO ZOOM

CANCELLING THE SELF CHECK MODE

Press "MENU" button on the main unit or remote control unit.

TEST PATTERN

This projector displays seven kinds of test patterns [Horizontal lines, Vertical lines, Dots, Crosshatch, White cross, Black cross and White (No pattern)] in the four colors (White, Red, Green and Blue).

Note: Because the above patterns can be displayed by each color without test equipment such as PC or SG, use it for simplified adjustments by your eyes and so on.

Procedure to display test patterns

Select "TEST PATTERN" on "EXT OPTION" menu and press "ENTER" button on the main unit or remote control unit.

Note: On the test pattern screen, pressing the up-arrow "▲ " or down-arrow "▼ " button allows the test pattern selection and the left-arrow "◄ " or right-arrow "► " button the color selection (White / Red / Green / Blue).

Canceling the test pattern display

Press "MENU" button on the main unit or remote control unit.

Flicker Adjustment Mode

If replacing the optical parts (Analysis / LCD / Lens block) of this projector and/or A-P.C.Board (assembly), enter the flicker adjustment mode and minimize the flicker.

Procedure to enter the adjustment mode

Select "FLICKER ADJUST" on "EXT OPTION" menu and press "ENTER" button on the main unit or remote control unit.

Note: "DESK setting (blue)" is displayed when entering the adjustment mode.

Adjustment Display and Contents

Setting value is increased and decreased with the right-arrow and left-arrow buttons. " ◄": Decrease, "► ": Increase

Adjust the setting value to minimize the flicker on the screen.

Execute the adjustment by 6 patterns below.

The pattern (adjustment display) is switched with the up-arrow "▲ " and down-arrow " ▼" buttons. "▲ ": Forward direction, "▼": Reverse direction

There are 6 patterns of "DESK setting (blue)", "DESK setting (red)", "DESK setting (green)", "CEILING setting (blue)","CEILING setting (red)" and "CEILING setting (green)".

The setting value is saved into this projector when the pattern is switched.

Canceling the flicker adjustment mode

Press "MENU" button on the main unit or remote control unit.

Note: When "MENU" button is pressed, the setting value at that time is saved into this projector and the adjustment mode is canceled.

↧

HOW TO REMOVE LAMP UNIT – LENS & HOW TO REPLACE LCD PANEL - PANASONIC LCD PROJECTOR - PT-LB60NTU / PT-LB60NTE / PT-LB60NTEA / PT-LB60U / PT-LB60EA / PT-LB55NTE / PT-LB55NTEA / PT-LB55EA

LAMP UNIT REMOVAL

- Turn the projector upside down.

- Loosen the 2 screws until they idle, remove the lamp unit cover.

- Loosen the 2 screws until they idle, remove the lamp unit with the handle.

When installing the lamp unit (or a new one) in the main unit, place it in a specified position and press the connector side and the opposite side of the lamp unit (arrow positions shown in the figure below), and confirm the lamp unit is inserted securely. Then, tighten the 2 screws fixing the lamp unit, and attach the lamp unit cover.

REMOVAL OF ANALYSIS BLOCK AND THE LENS

- Remove the lamp unit.

- Remove the A-P.C.Board block.

- Unscrew the 3 screws and remove the analysis block, LCD block and lens.

- Unscrew the 4 screws A and remove the lens.

- Unscrew the 2 screws B and remove the LCD block (the analysis block remains).

REMOVAL & REPLACEMENT OF LCD BLOCK

- Remove the A-P.C.Board block.

- Unscrew the 2 screws and remove the LCD block.

- Note: Be careful not to touch the surface of prism and LCD panel.

CLICK ON THE PICTURES TO ZOOM. Click ßat the top left of the browser, to come back.

- Remove the LCD block.

- Cut the 4 LCD panel installation spindles at the position A and remove the LCD panel.

- Cut the 4 LCD panel installation spindles at the position B and remove them.

Work carefully not to apply external force around the spindle part by using a cutter, cutting nipper or the like for cutting the spindle.

Adjust the height after the spindle is cut to 1 mm or less.

- Attach the base plate with 4 screws.

- Tighten the 2 screws temporarily just until new LCD panel (with the panel attachment and panel adjuster) can be shifted by your fingers.

- Reassemble the projector in the reverse order of disassembling, but leave the upper case and the screws fixing the A-P.C.Board block as they are removed.

- Adjust the convergence according to the "Convergence Adjustment".

- After the adjustment, while paying attention not to vary the adjusting result, tighten the 2 screws fixing the panel attachment with a hexagon head wrench.

- Reassemble the projector as it was.

↧

PANASONIC TX25MD1 - POWER SUPPLY [SMPS] - VIDEO OUTPUT - SCHEMATIC [Circuit Diagram] - TDA 4601 – TDA 6103Q

↧

↧

POWER SUPPLY SCHEMATIC - PANASONIC - TX-21JT2P - TX-21JT2P/B - 2SK2647-01MR

↧

HOW TO ENTER SERVICE MODE - PANASONIC - TX17LA1 – TX20LA1 - LCD TV

SERVICE MODE

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be adjusted by remote control in Service Mode.

SERVICE - 1

- In sound menu, set BASS to MAXIMUM, and set TREBLE to MINIMUM.

- Simultaneously press INDEXbutton on remote control and DOWNbutton on the TV set.

- Set the channel to CH99.

- Press HOLD button on remote control.

- To exit to Service mode, press NorPower button on remote control.

SERVICE 1, 2 - AND KEY COMMANDS

Click on tables to Zoom. Click ß at the top left of the browser, to come back.

Option Code Setting (17 inch model)If the memory IC (IC1004) or DG Board is replaced, option code should be re-memorized.

Spare part of IC1004 is already memorized all Data for TX-17LA1M.

If you use for other model, you should re-memorized the different option code in SERVICE 2 mode.Option Code Setting (20 inch model)

If the memory IC (IC1004) or DG Board is replaced, option code should be re-memorized.

Spare part of IC1004 is already memorized all Data for TX-20LA1M.

If you use for other model, you should re-memorized the different option code in SERVICE 2 mode.

OPTION DESCRIPTION

TX-17LA1M

↧

HOW TO DISASSEMBLE - PIONEER PDP-4280X - PLASMA DISPLAY

Function button panel.

Remove the two screws.

Remove the function button panel.

Side input cover

Remove the two screws.

Remove the side input cover.

Power button holder

Remove the two screws.

Remove the power button holder.

REAR CASE REMOVAL

Remove the two protect sheets C.

Remove the 23 screws. (AMZ30P060FTB)

Remove the nine screws. (TBZ40P080FTB)

Remove the four screws. (ABA1332)

Remove the four screws. (BBZ40P160FTB)

Remove the one screw. (ABA1341)

Remove the rear case (428).

When assembling the Rear Case (428), tighten the screws in the following sequence:

Tighten the screw (3-1).

Tighten the two screws (3-2).

Tighten other screws.

PCB ASS'Ys

Side I/O Assy

Remove the four screws.

Remove the two screws.

Remove the three screws.

Remove the side input panel.

42X Drve Assy.

Remove the two screws.

Remove the side input shield with PCB.

Diagnose the 42 X DRIVE Assy.

42Y Drive Assy

Remove the two screws

Remove the function button shield with PCB

Diagnose the 42 Y DRIVE Assy.

CLICK ON THE PICTURES TO ZOOM

How to remove the bridge connector connecting between the MAIN and TANSHI Assy’s

Grip the two short edges of the connector with long nose pliers.

Insert a finger between the long nose pliers and the board to protect the board and the mounted parts on the board from accidental damage by the pliers then, using your finger as a fulcrum and the pliers as a lever, pry the connector upward to remove it.

TERMINAL PANEL-B

Remove the 12 screws.

Remove the 10 screws.

Remove the three screws.

Remove the terminal panel B.

The wiring shown in the photo is different from the actual wiring, because the product in the photo is a prototype. Upon servicing, be sure to restore the original wiring of the unit after repair work.

FRONT CASE ASS'Y

Remove the one screw.

Remove the two screws.

Pull the lower part of the Front case Assy toward you and out.

Remove the Front case Assy, by pulling it upward.

ACCESS TO DIGITAL ASSY

Remove the six screws.

Remove the four screws.

Lift the Multi base section to the direction of the arrow.

SPEAKER BOX ASS'Y LEFT & RIGHT

LEFT

Remove the six screws.

Remove the four screws.

Lift the Multi base section to the direction of the arrow.

RIGHT

Remove the one screw.

Remove the switch holder (428).

Disconnect cables, connectors, as required.

Remove the two screws.

Remove the one screw.

Remove the one screw.

Remove the speaker box Assy R.

EXCHANGE OF SCAN IC

Loosen the jumper wire.

Remove the 42RLS&IR Assy by removing the one nylon rivet.

Remove the two screws.

Remove the locking wire saddle.

Unhook the six hooks.

Remove the panel holders V1 (427) and V2 (427).

Remove the three screws.

Remove the two screws.

Remove the front chassis VL (427)

↧

PIONEER PLASMA DISPLAY - PDP 4280X - How to replace a secondhand DIGITAL Assy that had been mounted in another product

When a second hand digital ass'y that had been mounted in other product is to be re-used.

As adjustment data for another product are already stored in the secondhand DIGITAL Assy, first delete those data then copy the backup data stored in the EEPROM on the SENSOR Assy.

Copying, using the Factory menu

- Plug in the AC cord, press the Power switch on the unit to set it to ON, then enter Standby mode.

- Turn on the power, using the remote control unit, then enter Panel Factory mode. Copy the backup data, as shown in the figure below:

CLICK ON PICTURE TO ZOOM

- Turn the power off.

Copying, using the RS-232C commands

- Turn on the unit, using the remote control unit or by issuing the PON command. Then issue the FAY command.

- Issue the UAJ command to delete data stored in the EEPROM on the DIGITAL Assy.

- Issue the BCP command to transfer the data stored in the EEPROM for backup.

- Turn the power off.

↧

↧

PIONEER PDP-4280X - How to copy Bck-Up Data - HOW TO CLEAR HISTORY DATA

TO COPY BACKUP DATA

Adjustment data are stored in the EEPROM (IC3156/4K) on the DIGITAL Ass’y in the production process. Those adjustment data are also automatically stored in the EEPROM (for backup: IC3652) on the SENSOR Assy. If the DIGITAL Ass’y is replaced, those adjustment data for backup can be copied from the EEPROM on the SENSOR Ass’y to a new DIGITAL Assy.

Backed up data

- Drive voltage adjustment value

- Hour-meter count

- Pulse-meter count

- Panel white balance adjustment value

- Serial No.

- Drive waveform adjustment value

- P-ON counter value

- PD/SD histories.

When the DIGITAL Assy is replaced with one for service (usual service). Copying the data backed up in the SENSOR Assy to the EEPROM on a new DIGITAL Assy can restore adjustment data. The EEPROM on the new DIGITAL Assy has no adjustment data, and the EEPROM for backup in the SENSOR Assy has adjustment data. After replacing the DIGITAL Assy, enter PANEL FACT. Mode, displays the PANEL INFORMATION page, then check if "NO DATA!" is set for "DIG. EEP" and "ADJUSTED" is set for "BACKUP". Then, proceed in the following steps:

Copying, using the Factory menu

- Plug in the AC cord, press the Power switch on the unit to set it to ON, then enter Standby mode.

- Turn on the power, using the remote control unit, then enter Panel Factory mode. Copy the backup data, as shown in the figure below.

- Turn the power off.

- After the DIGITAL Assy is replaced with one for service, be sure to check if "NO DATA!" is set for "DIG. EEP" on the PANEL INFORMATION page of the PANEL FACT. mode.

- If copying of the backup data fails in the above procedure, the red LED lights, and the blue LED flashes, as a warning that no backup data were copied.

- If both the DIGITAL and SENSOR Assys are to be replaced, first replace the SENSOR Assy, turn the unit on and back off again, then replace the DIGITAL Assy.

- Turn on the unit, using the remote control unit or by issuing the PON command. Then issue the FAY command.

- Issue the BCP command to transfer the data stored in the EEPROM for backup.

- Turn the power off.

It is assumed that settings for various items have been completed, using Factory menu or RS-232C commands.

Method using the Factory menu

- Set various setting/adjustment values.

- Proceed in the following steps.

- Turn the power off.

TO CLEAR HISTORY DATA

Clearance of various logs after the Assys are replaced.

Besides adjustment data, data on accumulated power-on time and logs on defective parts of the product are backed up. Some of those data must be cleared after the Assys are replaced for service.

Clearance of logs, using the RS-232C commandsCLICK ON THE CHART TO ZOOM

Notes: As the pulse-meter count is used for each correction function, it must be cleared when an Assy relevant to correction functions is replaced.

When clearing logs, using the RS-232C commands, first enter Factory mode (by issuing FAY or PFY), then issue the corresponding command. (2) Clearance of logs, using the Factory menu

- Plug in the AC cord, press the Power switch on the unit to set it to ON, then enter Standby mode.

- Turn on the power, using the remote control unit, then enter Panel Factory mode.

↧

WHAT ARE THE ADJUSTMENT WHEN THE SERVICE PANEL ASSY IS REPLACED - PIONEER PDP 4280X _ Plasma Display

ADJUSTMENTS AFTER PANEL REPLACEMENT

In the "PANEL-1ADJ" layer, the Panel White Balance value is reset to default, Panel Gamma is set to Straight, and Noise is

After the panel is replaced with one for service, voltage margin adjustment is required.

Basically, voltage margin adjustment is performed using the Panel Factory menu.

After the panel is replaced and the unit is turned on, clear the pulse meter first.For details on how to clear the pulse meter check previous posts here:

- As various corrections are made referring to the pulse-meter count to calculate how long the panel has been used, if adjustment of the panel for service is performed without clearing the pulse-meter count, proper adjustments will not be performed.

- The drive sequence for 60-Hz video is used for adjustment. When adjustment is made using the Panel Factory menu, the current drive sequence is displayed on the screen, as shown in the figure below. Make sure that 60VS is always indicated during adjustment.

Example of the On-Screen display during Panel Factory mode

CLICK ON THE PICTURES TO ZOOM

set to OFF.

In this case, *-- - - - -/****" (**** represents the current drive sequence) is displayed on the third line of the On-Screen display during Panel Factory mode.

If adjustment is performed using RS-232C commands, the following commands must be transmitted for preparation:

[PAV S00]: To set panel drive mode to Factory

[VFQ S03]: To set Drive Sequence to Video 60 Hz

[WBI S01]: To temporarily reset the Panel WB adjustment value to default (WBI S00 cancels this setting.)

[PGR S00]: To set the gamma R value to that for Factory mode

[PGG S00]: To set the gamma G value to that for Factory mode

[PGB S00]: To set the gamma B value to that for Factory mode

[DIZ S03]:Dither ON,L dither ON, noise OFF

If the unit is shut down during the above adjustment flow, resend the above commands from the beginning.

Replacement with the panel for service is completed. [Procedures for resetting corrections for change over time]

Procedures for stabilizing the panel before adjustment

If you perform the adjustment by RS-232C commands, the following commands must be added before going to the main flowchart (1):

[PAV S00]: To set panel drive mode to Factory

[WBI S01]: To temporarily reset the Panel WB adjustment value to default (WBI S00 cancels this setting.)

[PGR S00]: To set the gamma R value to that for Factory mode

[PGG S00]: To set the gamma G value to that for Factory mode

[PGB S00]: To set the gamma B value to that for Factory mode

[DIZ S03]:Dither ON,L dither ON, noise OFF

Main flowchart (2) - Checking VOL YNOFS3

Make sure that the values for VOL SUS(*1), VOL OFFSET, VOL RST P(*1), VOL XPOFS1,2(*1) and VOL YNOFS1, 3, 4 are the final setting values.

The tentative setting value becomes the final value.

↧

PIONEER _ PDP 4280XA – 4280XD – 428XD - TROUBLESHOOTING CHART [Whole Unit _ Power Supply]

↧

SHUTDOWN DIAGNOSIS - LED BLINKINGS - PIONEER PDP _ 4280XA – 4280XD – 428XD - Troubleshooting Chart

↧

↧

HOW TO ENTER SERVICE MODE - PROTECTIONS - PIONEER PDP _ 4280XD – 4280XA – 428XD

SERVICE MODE / FACTORY MODE

- By using a PDP service remote control)

- By issuing RS-232C commands )

During normal operation mode : Issue [FAY].

- How to exit Service Factory Mode

PDP service remote control : press [FACTORY] key.

# Supplied remote control unit : press [HOME MENU] key.

By issuing RS-232C commands)

Issue [FAN].REMOTE CONTROL CODE IN SERVICE FACTORY MODE

When ten seconds have passed since the [DRIVE OFF] key was pressed at the standby, it becomes invalid.

Press [POWER] key from the [DRIVE OFF] key pressing within ten seconds when you do power supply ON while driven OFF.

CLICK ON THE TABLE TO ZOOM

SERVICE FACTORY MODE TRANSITION CHART

FUNCTIONS WHEN ENTERING THE SERVICE FACTORY MODE

The settings for the following functions are set to OFF when Service Factory mode is entered (including when the “FAY” command is received) :

User data will be treated as follows:

- User data on picture-quality and audio-quality adjustments are not reflected, and factory-preset data are output (user data will be retained in memory). When the unit enters Service Factory mode, the current audio-quality adjustment data will be still be retained in memory.

- User-setting data will be applied to the various settings (items on the menus), signal formats, and the items that are associated with path change (HDMI settings, etc.).

- Data on screen (i.e., screen position; meaning clock dividers, and not including data on screen size). Are reset to the default values (data stored in memory will be retained). Screen size will be retained.

The keys labeled with the same names on the service remote control unit have the same functions as those of the supplied remote control unit.

For the keys not provided on the supplied remote control unit, see the explanations below:PROTECTION FUNCTIONS

HIGH-TEMPERATURE PROTECTION FUNCTION - 1

The panel temperature (TEMP1) reaches 70 °C, the limit for the maximum count of plasma discharge will be gradually decreased to lower the temperature of the panel.

- This function is activated based on the TEMP1 temperature.

- The limit for the maximum count of plasma discharge will be decreased 8 per 5 seconds.

- The lowest limit for the maximum count of plasma discharge is about 700.

- The maximum count of plasma discharge will begin to increase gradually if the panel temperature falls to the specified temperature.

HIGH-TEMPERATURE PROTECTION FUNCTION - 2

If the panel temperature (TEMP1) reaches 65 °C, the plasma-discharge count that is determined based on the input APL will be decreased. In actual operation, the ABL adjustment value will be offset.- This function is activated based on the TEMP1 temperature.

- The ABL adjustment value will be decreased by one step per 30 seconds.

- The ABL adjustment value will begin to increase gradually if the panel temperature falls to the specified temperature.

PANEL PROTECTION FUNCTION-1 [Protection against still picture]

If a still picture is displayed for 3 minutes or more, the limit for the maximum count of plasma discharge will be gradually decreased to minimize the effects of phosphor burn.- This function is activated after detection if the displayed picture is still (the picture will be considered to be still if only the mouse cursor is moved).

- The limit for the maximum count of plasma discharge will be decreased 8 per 5 seconds.

- The lowest limit for the maximum count of plasma discharge is about 700 (it takes about 15 minutes to reach the lowest limit, although the required time varies depending on the displayed picture).

- The maximum count of plasma discharge will begin to increase gradually if the displayed picture is changed to animated picture.

PANEL PROTECTION FUNCTION-2 [SCAN IC Protection]

If a particular load is applied to the SCAN IC, the limit for the maximum count of plasma discharge will be gradually decreased.

Note: How to decrease the brightness level in this function is the same as in high-temperature protection function 1

PANEL PROTECTION-3 [Protection against panel cracking]

A bright window, as shown in the figure on the right, on the screen increases the heat of the panel. If such a pattern is recognized on the screen, the limit for the maximum count of plasma discharge will be gradually decreased.

Note: How to decrease the brightness level in this function is the same as in high-temperature protection function 1

↧

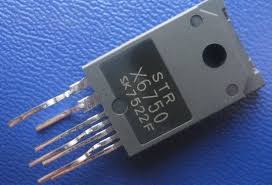

STR X6750F - SMPS POWER SUPPLY SCHEMATIC [Circuit diagram] - Horizontal & Vertical Scan Output Schematic - Samsung CL29Z50M CTV

↧

SAMSUNG CL29Z50M - CTV - TROUBLESHOOTING & ERROR MODES - Diagnosis

ERROR MODES

NO POWER

NO SOUND

NO POWER

CLICK ON PICTURES TO ZOOM. Click ß at the top left of the browser, to come back.

NO VIDEONO SOUND

Tuner Diagnosis

The RF / CTV signal is transmitted to the Tuner of the Main Board. If the signal is not received, check the following items.

- Power supply: 5V, 33V

- Check for RF defects: Check the IF output

- Check for AUDIO defect: Check the SIF Signal output

Micom Diagnosis

VSP/MSP/DRX Block ETC

- Power supply: 3.3V, 5V, 8V

- Check for input defects: Y/C(CVBS, S-VHS), 480i Y/Pb/Pr signal

This receives the signal from the Audio Processor (VCTI) and outputs the signal in7W+7W / 10W + 10W sound.

- Power supply : 14V

- Check for input defects : AMP-R,AMP-L

- Check for output defects : L+, L-, R+,R-

Troubleshooting Deflection Block

Countermeasures by Deflection Types

The screen is blank and only the relay repeats close and open when turning the power on. This happens when the vertical voltage or vertical signal is not supplied, and because the Micom operates for 5 to 10 seconds and then turns the power off by force as it cannot detect the vertical signal.

CHECK POINT

Check that the vertical output voltage is measured in the FBT terminal.

VCC (+) : +16.5V

VCC (-) : -16.5V

If you cannot measure the output voltage, check that the collector voltage of the horizontal TR is 1360V. If the voltage is measured, the problem is a defect in the FBT unit. (When you don't have an oscilloscope, and you can hear the high-voltage sound, you can determine that the horizontal TR is normal.)

Is the vertical input waveform output from the VCTI VDP Pin.

↧

SONY KV -21FA310 - KV-29FV210 - HORIZONTAL OUTPUT – VERTICAL OUTPUT & SMPS - Circuit Diagram - [2SK3568 – MCZ30001DB – ON3171R]

↧

↧

T'CON BOARD FAULTS - LED LCD - LG 47M6700 – 47M6710 – 47LM671Y - [Exchange T-Con Board - Part 1.]

↧

LG LED LCD TV - 47M6700 – 47M6710 – 47LM671Y - T'Con Board faults - Screen-shots - Part-2

↧

POWER SUPPLY UNIT [LED DRIVER] & MODULE FAULTS - LG 47M6700 – 47M6710 – 47LM671Y - LED LCD TV

↧