POWER SUPPLY TROUBLESHOOTINGRemember if a voltage is missing check for proper resistance before proceedings.

Understanding the Power On Sequence when Troubleshooting a possible Power Supply Failure will simplify the process of isolating which circuit board failed to operate properly. In this Section we will investigate the Power on Sequence and examine ways to locate quickly where the failure occurred.

Check the Power On LED for Operation. A Red LED indicates a presence of 5V STB and AC-ON/DETECT. Failure of the Power ON LED to light is an indication of loss of 5V STB or AC ON/ Detect remembers the 5V STB and AC-ON/DETECT are developed on the SMPS and sent to the Main Board.

Listen for Relay Click; the click of the Relay is an indication of RL-ON going high. RL-ON is sent from the Main Board to the SMPS and when present the U701 controls the Relay Operation. RL-ON going high and no Relay is a failure of the SMPS, RL-ON staying low is a failure of the Main Board.

Relay Operation means that the SMPS if working properly will output the 16V supply to the Main Board. This voltage will allow the Tuner, Audio and Video Circuits on the Main Board to function, and if connected to an Antenna Input, Audio would be present. If the Relays closed and these supplies failed suspect a problem with the SMPS.

The next step of operation calls for the M5V_ON line from the Main Board to the SMPS to go high on P803 pin 21. A high on the M5V_ON Line activates the 5V VCC line. Loss of 5V VCC results in no “Raster”, no Display Panel Reset, and no Y, Z, Control or X Board operation. Any of these boards or failure of the SMPS could cause loss of5V VCC and M5V_ON going high. M5V_ON staying low indicates a problem on the Main Board.

VS-ON is the last step of the Power Sequence and is responsible for bringing the VS and VA Voltages up. The VS-ON signal pin 20 P803 is sent from the Main Board to the SMPS as a high, VS and VA and full operation of the Display Panel are now enabled. Loss of VS-ON results in loss of VA and VS and no Raster, no Panel Display Reset but Audio would be present. If VS-ON went high and VS and VA where missing the problem could be caused by a failure on the SMPS or a circuit using these voltages. A Resistance check should narrow the possible failures quickly.

STATIC TEST

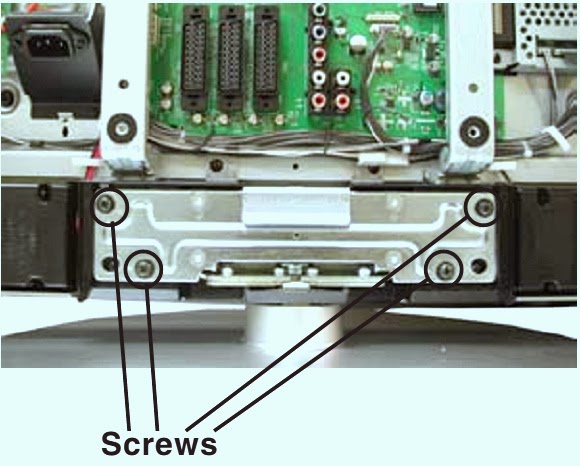

This test can confirm the proper operation of the SMPS without the need to exchange the board. This Power Supply can operate in a No Load State. This means that by applying AC power to CN101 and all other plugs disconnected, this power supply will function. Simply removing P803 (Lower Right-Hand Side of the Board), will cause the “AUTO” Pin 22 to go high from its normal low state allowing the Power Supply to go to full power on mode when AC Power is Supplied. Be careful after this test and make sure the VA and VS lines have discharged before reconnecting the supply cables.

If either Y-SUS or Z-SUS is causing the power supply to shutdown, unplug the Z-SUS. This will allow the Y-SUS to function. If you unplug the Y-SUS from the SMPS, and jump the 5V VCC line to the Y- SUS for Control Board Power the Z-SUS will function.

If the Y-SUS and Z-SUS Boards are working normal, when the SMPS comes up to full power on, “Display Panel Reset” will be visible. Shorting the Auto Pattern Gen. test points at this time should result with test patterns on the screen (if not check for 16V and VA to the X Boards).

For a “Stand-Alone” static test for the Power Supply, apply the usual 2-100Watt light Bulbs test on the Vs output line for a simulated load. If the Power Supply operates in this condition, it is assured it can maintain its output power under load.

Ground the Auto Ground (Pin 22) on P803

AC Power Applied AC Det (Pin 18) and 5V STB (Pins 9 ~ 12) are 5V.

100Ω¼ watt resistor added from 5V STB (Pins9 ~ 12) to RL ON (Pin 19) closes relay RL101 turning on the 16V Supply.

100Ω¼ watt resistor added from 5V STB (Pins 9 ~ 12) toM5V_ ON (Pin 21) brings the 5V VCC line high.

100Ω¼ watt resistor added from 5V STB (Pins 9 ~ 12) toVS _ON (Pin 20) bringsthe VA and VS Lines high.

USING BULBS AS LOAD

Unplug all connectors. Using two 100W light bulbs [filament type only], attach one end to Vs P801 pin 1 & 2 and the other end to chassis ground. Apply AC to CN101. If the light bulbs turn on, allow the SMPS to run for several minutes to be sure it will operate under load. If this test is successful and all the other voltages are generated, can be assured the power supply is OK.

Note: The light bulb test is not necessary for the SMPS to turn on and stay on. This SMPS will run without a load. But, it is necessary to test the SMPS under load.

CLICK ON THE PICTURES TO MAGNIFY