↧

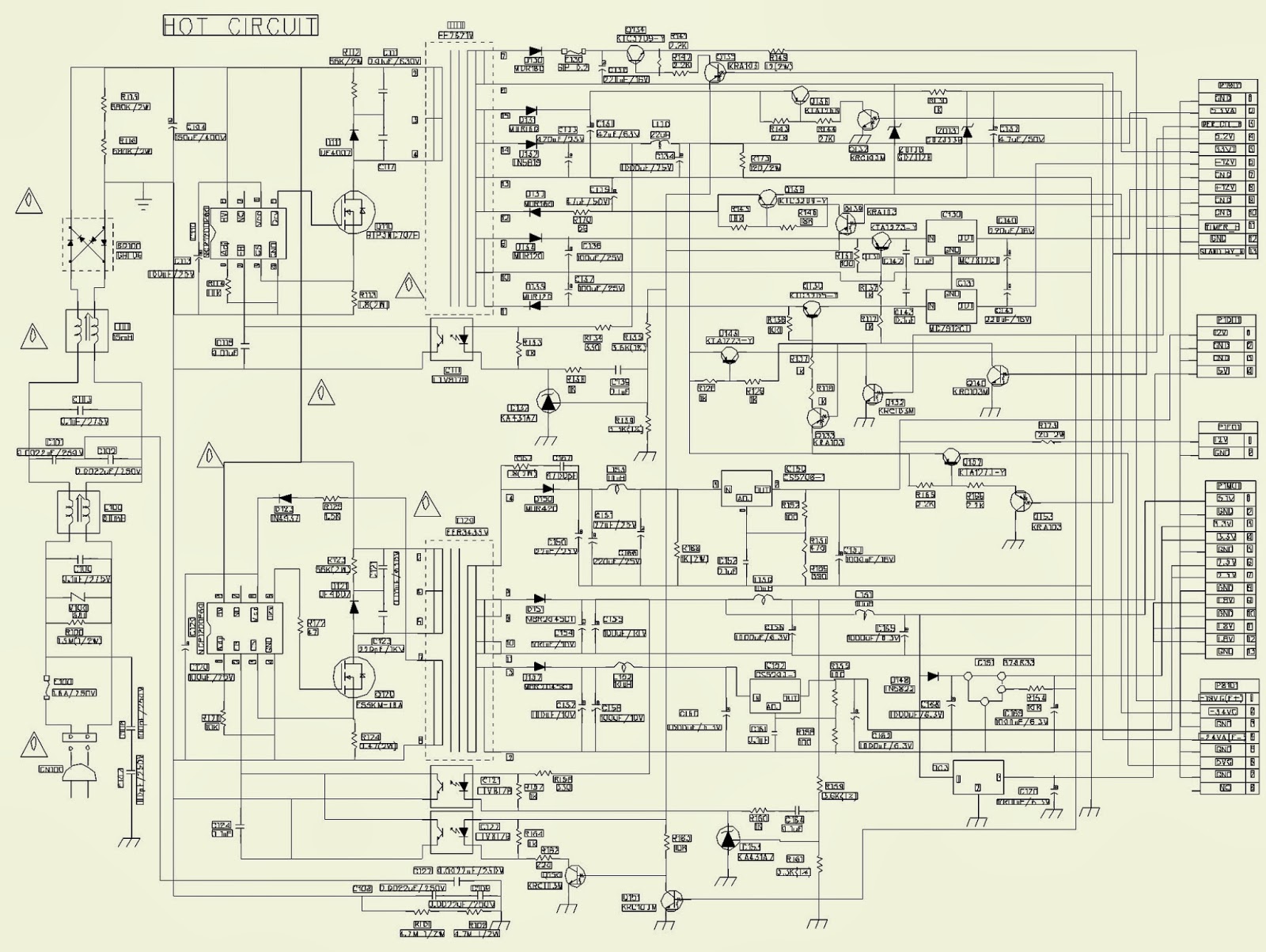

PHILIPS 14PV Series - TV-VCR COMBO - SMPS [POWER SUPPY] - SCHEMATIC

↧

PHILIPS MAGNAVOX - 20PT6245/37 - MAIN SMPS - DVD POWER - SCHEMATIC

↧

↧

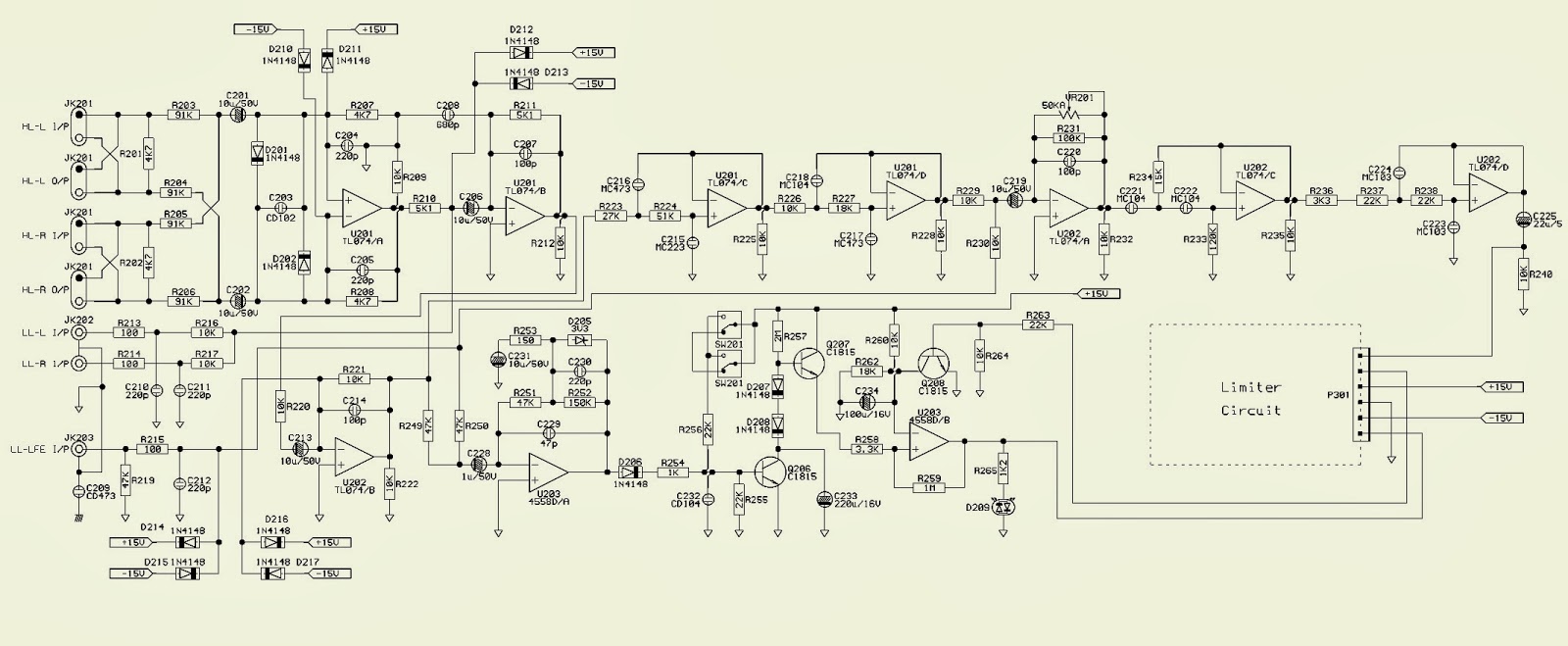

JBL JSR-400 – POWER – AMP - SCHEMATIC [STK-4192]

↧

JBL JSR-400 Dolby Pro-Logic Audio/Video Surround Receiver _ TROUBLESHOOTING

TROUBLESHOOT

If there is no sound from any of the speakers, check the following:

Make sure the receiver is plugged into an active AC wall outlet.

Push “Speakers” button on the receiver.

Make sure there is a source – for example, a VCR or television – hooked up to the VCR or tape/aux input jacks on the receiver.

Make sure that the program material is playing.

Recheck the hookup connections.

If most of the sound comes from the center-channel with little or no information from the surround channels, note the following:

Although most of today’s televisions are equipped with stereo audio output jacks, some stereo televisions have poor audio sections and are unable to provide a Dolby speaker, Pro Logic encoded signal. In the unlikely event that you experience this problem, connecting the audio outputs from your Hi-Fi VCR, laser disc player, DVD player or satellite receiver directly to one of the inputs on the receiver will provide a proper audio signal and allow you to enjoy true Dolby Pro Logic surround sound.

If there is no sound from the surround speakers or it is very low, check the following

Check all connections between amplifier and each of the speakers.

Raise the surround volume from the remote control.

Make sure the TV show or movie you are watching is recorded in Dolby Surround.

Make sure Dolby Pro Logic is engaged.

If there is no sound from the center speaker, check the Following

Make sure that the processor is in the Pro Logic, or 3 Stereo mode. If it is in Phantom or Stereo mode, the center speaker will not play.

Check the connections between the receiver and the center speaker.

If you are having trouble picking up radio stations, check the following:

Make sure the antenna is hooked up properly.

Depending on your distance from the station’s transmitter, you may need to install an FM antenna on the roof or in the attic.

Receiver inoperative

Faulty AC power cord. (FL indicator does not light) Replace.

Defective power switch. Replace.

Broken wire in the power transformer. Replace the power transformer.

Blown fuse. Replace the fuse.

Fuse blows when power is turned on.

Defective power transformer. Replace.

Short on the primary or secondary of the transformer circuitry. Repair the short.

Damaged rectifier (D20) or damaged “transistor (Q3, Q11, Q12).” Replace the defective component/s.

Short circuit in the amplifier circuit. Replace the shorted component/s in the amplifier circuit.

FL indicator lights but no sound

Defect in IC3 on the Main Board. from both channels. Replace the defective component/s.

One channel does not work when volume is at maximum with a test Signal applied to the center terminal of volume control VR1 of The dead channel.

“Defect in IC2,IC3 on the Main Board” signal applied to the center terminal volume is at maximum with a test channel. Locate and correct the defect.

Break in copper foil of printed circuit board. Repair the trace.

Short in speaker output terminal. Repair or replace.

Speaker works normally but Headphones inoperative.

Headphone plug does not mate with jack. Replace the jack.

“Defective resistor R52, R53.” Replace.

FM inoperative

Defective front-end. (PACK1) Replace.

Defective FM switch. Replace the switch.

“Defective transistors Q1,Q2,Q3,Q201,” “Q202 or IC2, IC3, IC4" Replace the defective transistor(s) or IC(s).

Defective coil T4. Replace the coil(s).

Defective lead-in. Repair or replace the lead-in.

“Ceramic filters F101, F102 defective.” Replace the defective ceramic filter(s).

Defective controller circuit component. Replace.

Poor multiplex separation

Improper adjustment. Readjust VR401.

IC4 defective. Replace.

Variable resistor VR401 defective. Replace the variable resistor.

STEREO indicator does not light.

Defective indicator in FL. Replace.

Defective IC4. Replace the defective component.

FM volume not sufficient.

If volume from both L and R channels is not loud enough: Front end section defective. “Faulty IC3, Coil T4" Defective C412 on Tuner Board. If sound of one

channel is not loud enough: “Defective Q401, Q402"

AM inoperative A) Damaged IC3 of tuner board. Replace.

“Defective T1, T2, T6 or F202 of ” Tuner Board. Replace the defective component(s).

“Resistors R301, R302 defective.” Replace the defective component(s).

“Capacitors C438, C322, C412 defective.” Replace the defective capacitor(s).

Defective AM switch. Replace.

“Defective varicap diodes VC1, VC2.” Replace varicap diode(s).

Damaged AM loop antenna. Repair or replace.

Defective controller circuit component. Replace.

Bass control has no effect.

Variable resistor BASS defective. Replace.

“Defective R60, R63, C47, C48, C52, C53" Replace the defective component(s).

Treble control has no effect.

Variable resistor TREBLE defective. Replace

“Defective R70, R73, R77, R79, ” “C58, C61, C63, C64.” Replace the defective component(s).

Auto tune inoperative. (UP/DOWN)

Poor contact on Up/Down key. Repair or replace.

Defective IC on Front Board. Replace.

Defective tuner circuit components. Replace.

“In case of FM only, improper adjustment” of FM front-end. Readjust.

Manual tune inoperative. (UP/DOWN)

Poor contact in Up/Down key. (AM or FM) Replace.

Defective IC1 on Front Board. Replace.

Memory setting (Keys 1-10) inoperative.

Poor contact on memory keys 1-10. Replace

Poor contact on memory set key. Replace.

Defective IC1 on Front Board. Replace the defective component.

FL inoperative.

FL defective. Replace.

Defective IC1 on Front Board. Replace.

Noisy volume control.

Defective volume control. Replace.

“Defective capacitors C1, C2.” Replace the defective capacitor(s).

Remote Control Unit inoperative.

Weak battery. Replace.

Defective. Replace.

Defective IC1 on Front Board. Replace.↧

JBL- SCS 140 - SCS146 _ SCHEMATIC DIAGRAM

↧

↧

JBL SUB-10 SUB-WOOFER - SCHEMATIC [CIRCUIT DIAGRAM] - AMP-SUBWOOFER

↧

harman-kardon - CITATION-16 SERIES - STEREO AMP - SCHEMATIC [Circuit Diagram]

SCHEMATICS

Click on the pictures to Zoom In

In order to operate in the Bridge mode first perform the internal modification. Once this is accomplished speaker must now be connected between the left (+) terminal RED, and the right (+) terminal RED. The negative Ground, of black terminals of each channel is not used.To accomplish this, use two banana plugs supplied, simply connect one lead of the speaker to one terminal of one banana plug, and connect other lead of the speaker to one terminal of the other banana plug. Connect the two banana plugs as shown here, making sure that each end of the banana plug with the wire attached goes into the RED receptacle.

The LED display in the bridge mode is the sum of each channels's individual display; that is; Stereo Mode 160W Chan-A, 160W Chan-B is equal to 320W total in bridge mode.

↧

HOW TO ENTER SERVICE MODE - PANASONIC - TC14A04P - TC20A04P - TC20B04

SERVICE MODE

- Set the 'OFF TIMER' to 30 minutes.

- Press 'RECALL' KEY & VOL(-) key on the remote control, simultaneously. After a couple of seconds, 'CHK' should appear on the top right side of the screen. [Service Mode]

- To change the memory data, press 'MUTE'& 'VOLUME (-)' simultaneously while the OSD is still on CHK-1 mode.

- Key '4' moves forward in the memory, and key '3' moves back in the memory.

- To alter from CHK-1 mode to CHK-2 or CHK-3 modes, press key '2' to move forward, and the key '1' to move back.

- To EXIT service mode, press 'NORMAL' on the remote control unit.

CHK-1 OPTIONS

To select an item, press '4' to move forward, and '3' to move backward. After having selected the desired option, adjust it by pressing 'VOL (-) 0r 'VOL (+) keys.

↧

PHILIPS 40PFL3606D - HOW TO REMOVE STAND - BACK COVER

STAND & BACK COVER REMOVAL

For easy servicing of a TV set, the set should be put face down on a soft flat surface, foam buffers or other specific workshop tools. Ensure that a stable situation is created to perform

Assy/Panel Removal

Instructions below apply to the 40PFL3606D/78, but will be similar for other models.

Rear Cover

Remove fixation screws [2] and [3] that secure the rear cover. It is not necessary to remove the stand first.

Lift the rear cover from the TV. Make sure that wires and flat foils are not damaged while lifting the rear cover from the set.

LCD Panel & STAND

Remove the Stand [A].

Remove the Speakers/Subwoofer [B].

Remove the PSU [C], SSB [D] and TCON (E).

Remove the IR/LED board [F].

Remove the Local Control board [G].

Remove the clamps [1].

Remove all metal subframes [2] that do not belong to the LCD display.

CLICK ON THE PICTURES TO ZOOM IN

↧

↧

PHILIPS TVs_SERVICE MODE & ADJUSTMENTS -DETAILED DESCRIPTION -SAM _ SDM

Never try to enter Service Mode, and adjust any data values stored, without proper knowledge and experience. Read carefully all these descriptions, and be confident that you can do it.

SERVICE MODE

The Service Mode feature is split into four parts:

> Service Default Mode (SDM).

> Service Alignment Mode (SAM).

> Customer Service Mode (CSM).

> Computer Aided Repair Mode (ComPair).

SDM and SAM offer features, which can be used by the Service engineer to repair/align a TV set. Some features are:

> A pre-defined situation to ensure measurements can be made under uniform conditions (SDM).

> Activates the blinking LED procedure for error identification when no picture is available (SDM).

The possibility to overrule software protections when SDM is entered via the Service pins.

Make alignments (e.g. White Tone), (de)select options, enter options codes, reset the error buffer (SAM).

> Display information (“SDM” or “SAM” indication in upper right corner of screen, error buffer, software version, operating hours, options and option codes, sub menus).The CSM is a Service Mode that can be enabled by the consumer. The CSM displays diagnosis information, which the customer can forward to the dealer or call centre. In CSM mode, “CSM”, is displayed in the top right corner of the screen.

* Increase the home repair hit rate.

* Decrease the number of nuisance calls.

* Solved customers' problem without home visit.

ComPair Mode is used for communication between a computer and a TV on I2C /UART level and can be used by a Service engineer to quickly diagnose the TV set by reading out error codes, read and write in NVMs, communicate with ICs and the uP (PWM, registers, etc.), and by making use of a fault finding database. It will also be possible to up and download the software of the TV set via I2C with help of ComPair. To do this, ComPair has to be connected to the TV set via the ComPair connector, which will be accessible through the rear of the set (without removing the rear cover).

Life Timer

During the life time cycle of the TV set, a timer is kept (called “Op. Hour”). It counts the normal operation hours (not the Stand-by hours). The actual value of the timer is displayed in SDM and SAM in a decimal value. Every two soft-resets increase the hour by +1. Stand-by hours are not counted.

Software Identification, Version, and Cluster

The software ID, version, and cluster will be shown in the main menu display of SDM, SAM, and CSM. The screen will show: “AAAAAAB-XX.YY”, where: • AAAAAAis the chassis name: L11M11. Bis the region indication: E= Europe, A= AP/China, U = NAFTA, L= LATAM. XXis the main version number: this is updated with a major change of specification (incompatible with the previous software version). Numbering will go from 01 - 99 and AA - ZZ.

> If the main version number changes, the new version number is written in the NVM.

> If the main version number changes, the default settings are loaded.

> YYis the sub version number: this is updated with a minor change (backwards compatible with the previous versions) Numbering will go from 00 - 99.

> If the sub version number changes, the new version number is written in the NVM.

> If the NVM is fresh, the software identification, version,and cluster will be written to NVM

Display Option Code Selection

When after an SSB or display exchange, the display option code is not set properly, it will result in a TV with “no display”. Therefore, it is requiredto set this display option code after such a repair. To do so, press the following key sequence on a standard RC transmitter: “062598” directly followed by MENU/HOMEand “xxx”, where “xxx” is a 3 digit decimal value ofthe panel type, see sticker on the side/bottom of the cabinet. When the value is accepted and stored in NVM, the set will switch to Stand-by to indicate that the process has been completed.

Service Default Mode (SDM)

Purpose: Set the TV in SDM mode in order to be able to create a predefined setting for measurements to be made. In this platform a simplified SDM is introduced (without protection override and without tuning to a predefined frequency).

Specifications

> Set linear video and audio settings to 50%, but volume to 25%. Stored user settings are not affected.

> Set Smart Picture to “Game”.

> Set Smart Sound to “Standard”.

> Tune channel to:

> for analogue SDM: channel 3 (61.25 MHz)

> for digital SDM: channel 26 (545.143 MHz).

> For digital SDM: set PID default from the stream.

> All service-unfriendly modes (if present) are disabled, since they interfere with diagnosing/repairing a set. These service unfriendly modes are:

> (Sleep) timer.

> Blue mute/Wall paper.

> Auto switch “off” (when there is no “ident” signal).

> Hotel or hospital mode.

> Child lock or parental lock (manual or via V-chip).

> Skipping, blanking of “Not favourite”, “Skipped” or “Locked” presets/channels.

> Automatic storing of Personal Preset or Last Status settings.

> Automatic user menu time-out (menu switches back/OFF automatically.

How to Activate

To activate analogueSDM, use oneof the following methods:

> Press the following key sequence on the RC transmitter: “062596” directly followed by the MENU button.

> Short one of the “Service” pads on the TV board during cold start Then press the mains button (remove the short after start-up).

Caution: When doing this, the service-technician must know exactly what he is doing, as it could damage the television set.

To activate digitalSDM:

> Press the following sequence on the RC transmitter: “062593” directly followed by the MENU button.

On Screen Menu

After activating SDM, the following items are displayed, with “SDM” in the upper right corner of the screen to indicate that the television is in Service Default Mode.

Menu items and explanation:

> xxxxx: Operating hours (in decimal).

> AAAAAAB-XX.YY: See paragraph Software

Identification, Version, and Clusterfor the SW name definition.

> ERR: Shows all errors detected since the last time the buffer was erased in format <xxx> <xxx> <xxx> <xxx> <xxx> (five errors possible).

> OP: Used to read-out the option bytes. Ten codes (in two rows) are possible.

How to Navigate

As this mode is read only, there is not much to navigate. To switch to other modes, use one of the following methods:

> Command MENU from the user remote will enter the normal user menu (brightness, contrast, color, etc...) with “SDM” OSD remaining, and pressing MENU key again will return to the last status of SDM again.

> To prevent the OSD from interfering with measurements in SDM, command “OSD” or “i+” (“STATUS” or “INFO” for NAFTA and LATAM) from the user remote will toggle the OSD “on/off” with “SDM” OSD remaining always “on”.

# Press the following key sequence on the remote control transmitter: “062596” directly followed by the INFO[i+]/OK button to switch to SAM (do not allow the display to time out between entries while keying the sequence).

How to Exit

Switch the set to Stand-by by

> pressing the standby button on the remote control transmitter or on the television set, or

> via a standard RC-transmitter by keying the “00” sequence. If you switch the television set “off” by removing the mains (i.e., unplugging the television), the television set will remain in SDM when mains is re-applied, and the error buffer is not cleared. The error buffer will only be cleared when the “clear” command is used in the SAM menu.

Note: If the TV is switched “off” by a power interrupt while in SDM, the TV will show up in the last status of SDM menu as soon as the power is supplied again. The error buffer will not be cleared.

In case the set is accidentally in Factory mode (with an “F” displayed on the screen), pressing and holding “VOL-“ button for 5 seconds and then followed by pressing and holding the “CH-” button for another 5 seconds should exit the Factory mode.

Service Alignment Mode (SAM)

Purpose

> To change option settings.

> To display / clear the error code buffer.

> To perform alignments.

Specifications

> Operation hours counter (maximum five digits displayed).

> Software version, error codes, and option settings display.

> Error buffer clearing.

> Option settings.

> Software alignments (White Tone).

> NVM Editor.

> Set screen mode to full screen (all content is visible).

> Set Smart Picture to “Game”.

How to Activate

To activate SAM, use one of the following methods:

> Press the following key sequence on the remote control transmitter: “062596” directly followed by the INFO[i+] /OK button. Do not allow the display to time out between entries while keying the sequence.

> Or via ComPair.

After entering SAM, the following items are displayed, with “SAM” in the upper right corner of the screen to indicate that the television is in Service Alignment Mode.

System Information.

> Op Hour:This represents the life timer. The timer counts normal operation hours, but does not count Stand-by hours.

>MAIN SW ID

> ERR:Shows all errors detected since the last time the buffer was erased. Five errors possible.

> OP1/OP2:Used to read-out the option bytes. Ten codes are possible.

Tuner.

> AGC Adjustment:

Store:To store the data.

# Clear. Erases the contents of the error buffer. Select this menu item and press the MENU RIGHT key on the remote control. The content of the error buffer is cleared.

#Options.To set the option bits.

# RGB Align.To align the White Tone.

# NVM Editor.To change the NVM data in the television set.

# Upload to USB.

# Download from USB.

# Initialise NVM.To initialize a (corrupted) NVM. Be careful, this will erase all settings!

# Auto ADC.

# EDID Write Enable.Enables EDID writing (not applicable to Berlinale sets).

# Service Data.Virtual Key board for character input entry.

How to Navigate

> In the SAM menu, select menu items with the UP/DOWN keys on the remote control transmitter. The selected item will be indicated. When not all menu items fit on the screen, use the UP/DOWN keys to display the next / previous menu items.

> With the LEFT/RIGHT keys, it is possible to: – Activate the selected menu item. – Change the value of the selected menu item. – Activate the selected sub menu.

> When you press the MENU button twice while in top level SAM, the set will switch to the normal user menu (with the SAM mode still active in the background). To return to the SAM menu press the MENU button.

> The “INFO[i+]/OK” key from the user remote will toggle the OSD “on/off” with “SAM” OSD remaining always “on”.

> Press the following key sequence on the remote control transmitter: “062596” directly followed by the MENU button to switch to SDM (do not allow the display to time out between entries while keying the sequence).

How to Store SAM Settings

To store the settings changed in SAM mode (except the OPTIONS and RGB ALIGN settings), leave the top level SAM menu by using the POWER button on the remote control transmitter or the television set. The mentioned exceptions must be stored separately via the STORE button.

How to Exit

Switch the set to STANDBY by pressing the mains button on the remote control transmitter or the television set, or by keying-in the “00” sequence on a standard RC-transmitter.

Note: When the TV is switched “off” by a power interrupt while in SAM, the TV will show up in “normal operation mode” as soon as the power is supplied again. The error buffer will not be cleared.

> In case the set is in Factory mode by accident (with “F” displayed on screen), pressing and holding “VOL-“ button for 5 seconds and then followed by pressing and holding the “CH-” button for another 5 seconds should exit the Factory mode.

Error Codes

Error codes are required to indicate failures in the TV set. In principle a unique error code is available for every:

> Activated (SW) protection.

> Failing I2C device.

> General I2C error. The last five errors, stored in the NVM, are shown in the Service menu’s. This is called the error buffer. The error code buffer contains all errors detected since the last time the buffer was erased. The buffer is written from left to right. When an error occurs that is not yet in the error code buffer, it is displayed at the left side and all other errors shift one position to the right. An error will be added to the buffer if this error differs from any error in the buffer. The last found error is displayed on the left. An error with a designated error code neverleads to a deadlock situation. It must always be diagnosable (e.g. error buffer via OSD or blinking LED or via ComPair).In case a failure identified by an error code automatically results in other error codes (cause and effect), only the error code of the MAIN failure is displayed.

ERROR CODE TABLE

How to Read the Error Buffer

You can read the error buffer in three ways:

> On screen via the SAM/SDM/CSM (if you have a picture).

Example:

#– ERROR: 0 0 0 0 0: No errors detected

# ERROR: 6 0 0 0 0: Error code 6 is the last and only detected error

# ERROR: 9 6 0 0 0: Error code 6 was detected first and error code 9 is the last detected (newest) error

# Via the blinking LED procedure (when you have no picture).

Error codes

The “layer 1” error codes are pointing to the defective board. They are triggered by LED blinking when CSM is activated. In the LC10 platform, only two boards are present: the SSB and the PSU/IPB, meaning only the following layer 1 errors are defined:

> 2: SSB

> 3: IPB/PSU

> 4: Display

How to Clear the Error Buffer

The error code buffer is cleared in the following cases:

> By using the CLEAR command in the SAM menu:

> By using the following key sequence on the remote control transmitter: “062599” directly followed by the OK button.

> If the contents of the error buffer have not changed for 50 hours, the error buffer resets automatically.

Note: If you exit SAM by disconnecting the mains from the television set, the error buffer is not reset..ERROR CODE TABLE

The Blinking LED Procedure

The software is capable of identifying different kinds of errors. Because it is possible that more than one error can occur over time, an error buffer is available, which is capable of storing the last five errors that occurred. This is useful if the OSD is not working properly. Errors can also be displayed by the blinking LED procedure. The method is to repeatedly let the front LED pulse with as many pulses as the error code number, followed by a period of 1.5 seconds in which the LED is “off”. Then this sequence is repeated.

Example (1): error code 4 will result in four times the sequence LED “on” for 0.25 seconds / LED “off” for 0.25 seconds. After this sequence, the LED will be “off” for 1.5 Sconds. Any RC command terminates the sequence. Error code LED blinking is in red color.

Example (2): the content of the error buffer is “129600”

After entering SDM, the following occurs:

> 1 long blink of 5 seconds to start the sequence,

> 12 short blinks followed by a pause of 1.5 seconds,

> 9 short blinks followed by a pause of 1.5 seconds,

> 6 short blinks followed by a pause of 1.5 seconds,

> 1 long blink of 1.5 seconds to finish the sequence,

> The sequence starts again with 12 short blinks.

Displaying the Entire Error Buffer

Additionally, the entire error buffer is displayed when Service Mode “SDM” is entered.↧

SONY DVP NS51P - HOW TO TAKE OUT DISC IN EMERGENCY - [POWER OFF]

TAKE OUT DISC AT POWER OFF - Applicable to - DVP-NS15/NS51P/NS43P/NS53P/K56P

- Open dust cover to access to a hole insert a tapering driver into the aperture of the unit bottom, and move the lever of chuck can in the direction of the arrow A. (See Fig)

- Draw out the tray in the direction of the arrow B, and remove a disc. (See Fig)

- After removing the disc, push in the direction of arrow C until the tray fully in.

- Move the lever of chuck cam in the direction of arrow D

CLICK ON THE PICTURES TO ZOOM IN

↧

DVP SONY NS15/NS51P/NS43P/NS53P/K56P - POWER SUPPLY [SMPS] - SCHEMATIC

↧

OPTICAL PICK-UP REPLACEMENT - SONY - DVP-NS15/NS51P/NS43P/NS53P/K56P

DISASSEMBLE PROCEDURE

LOADING ASSEMBLY

CLICK ON THE PICTURES TO MAGNIFY

OPTICAL PICK-UPNote:

Solder short land before remove the FMO-009 Flat Flexible Cable from 24 pin BU connector.

Laser Diode in the optical Device is very sensitive to Surge Current or ElectroStatic Discharge (ESD). After take-out FMO-009 Flat Flexible Cable from CN101 of MV-47/MV-48 board immediately ground FMO-009 Flat Flexible Cable pattern using short clip. Metal paper clip can be used as short clip.

↧

↧

SONY KLV 32L500A - POWER SUPPLY SCHEMATIC [Circuit Diagram] _ FA5501AN-D1-TE1_2SK2158_2SK4096

↧

LG 60PG60 - TROUBLESHOOTING - PLASMA TELEVISION [PU 82C CHASSIS]

↧

Va & Vs VOLTAGE ADJUSTMENT - LG 60 Inch - 50 Inch & 42 Inch PLASMA TVs

ADJUSTMENTS

Each PCB assembly must be checked by check JIG set. (Because power PCB Assembly damages to PDP Module. So be careful)

PSU(Power Supply Unit) Voltage Adjustment (Va, Vs Voltage Adjustment).

Adjust the voltages Va and Vs supplied from the PSU to the module within the specified range of each module to supply the stable power.

Adjustment (60”). Va Voltage Adjustment

- Connect + terminal of D.M.M to Va pin of P812 and connect –terminal to GND pin of P812.

- Adjust VR901 voltage to match that of the label on the Top/Right of the panel. (Deviation : ±0.5V)

- Connect + terminal of D.M.M to Vs pin of P812 and connect –terminal to GND pin of P812.

- Adjust VR951 voltage to match that of the label on the Top/Right of the panel. (Deviation : ±0.5V)

Adjustment (50”). Va Adjustment

- Connect + terminal of D.M.M to Va pin of P12 and connect –terminal to GND pin of P12.

- Adjust VR951 voltage to match that of the label on the Top/Right of the panel. (Deviation : ±0.5V)

- Connect + terminal of D.M.M to Vs pin of P12 and connect –terminal to GND pin of P12.

- Adjust VR901 voltage to match that of the label on the Top/Right of the panel. (Deviation : ±0.5V)

Adjustment(42”). Va Voltage Adjustment

- Connect + terminal of D.M.M to Va pin of P812 and connect –terminal to GND pin of P812.

- Adjust VR901 voltage to match that of the label on the Top/Right of the panel. (Deviation : ±0.5V)

- Connect + terminal of D.M.M to Vs pin of P812 and connect –terminal to GND pin of P812.

- Adjust VR951 voltage to match that of the label on the Top/Right of the panel. (Deviation : ±0.5V)

↧

PANASONIC KX-MB783-BR _ SERVICE CODES - TROUBLESHOOTING - INITIALIZATION

TO ENTER THE REMOTE PROGRAMMING MODE & CHANGING SERVICE CODES

If, after the call is connected, the customer describes the situation and it is determined that the problem can be corrected by making parameter changes, this function makes it possible to change parameters such as the user code and service code from another fax (using DTMF tones). Therefore, travel to the customer's location isn't required. However, it is not possible to change all the parameters remotely (PROGRAM MODE TABLE(P.98)). The function used to accomplish this is remote programming.

First, in order to check the current status of the service code parameter, print out the setup list (code: 991) and the service list (code: 999) from the customer's fax machine.

Based on this, the parameters for the desired codes can be changed.

The procedure for changing and listing parameters is described on ENTERING THE REMOTE PROGRAMMING MODE AND CHANGING SERVICE CODES. Also, before exiting the remote programming-mode, it is advisable to obtain a new list to confirm that the changes were made correctly.

Hint: Since the connected telephone is in use during the remote programming mode, it may be helpful to ask the customer to switch to the speaker phone. This frees the customer from the need to remain right next to the fax while you are making parameter settings. When finished, inform the customer. Also note that in very noisy locations where the DTMF tones are not audible, the remote programming function will not work.ENTERING THE REMOTE PROGRAMMING MODE AND CHANGING SERVICE CODES.

CLICK ON THE TABLES TO ZOOM IN

TROUBLESHOOTING

Troubleshooting is for recovering quality and reliability by determining the broken component and replacing, adjusting or cleaning it as required. First, determine the problem then decide the troubleshooting method. If you have difficulty finding the broken part, determine which board is broken. (For example: the Main PCB, Sensor PCB, etc.) The claim tag from a customer or dealer may use different expressions for the same problem, as they are not a technician or engineer. Using your experience, test the problem area corresponding to the claim. Also, returns from a customer or dealer often have a claim tag. For these cases as well, you need to determine the problem. Test the unit using the simple check list on SIMPLE CHECK LIST(P.104). Difficult problems may be hard to determine, so repeated testing is necessary.

Determine the symptom and the troubleshooting method.

INITIALIZATION

There are two types of initialization, one is the short initialization (about 3 seconds) and the other is the long initialization (about 10 seconds). The short initialization makes the unit enter the standby mode. The long initialization makes the unit enter the standby mode after cleaning or detecting the rest of toner.

↧

↧

Personal Facsimile MS KX FT932BR - PANASONIC _ SMPS SCHEMATIC _ SERVICE MODE

SERVICE MODE

The programming functions are used to program the various features and functions of the machine, and to test the machine. This facilitates communication between the user and the service man while programming the unit.

There are 2 basic categories of programming functions, the User Mode and the Service Mode.

The Service Mode is further broken down into the normal and special programs. The normal programs are those listed in the Operating Instructions and are available to the user. The special programs are only those listed here and not displayed to the user.

In both the User and Service Modes, there are Set Functions and Test Functions. The Set Functions are used to program various features and functions, and the Test Functions are used to test the various functions. The Set Functions are accessed by entering their code, changing the appropriate value, then pressing the SET key. The Test Functions are accessed by entering their code and pressing the key listed on the menu. While programming, to cancel any entry, press the STOP key.

SMPS SCHEMATIC

CLICK ON THE PICTURES TO ZOOM IN

↧

MS_KX - FT932-BR-B - PANASONIC Personal Facsimile _ TROUBLESHOOTING

TROUBLESHOOT

Defective ITS (Integrated Telephone System) Section. No handset and monitor transmission / reception:

Following the ITS section or NCU section, search for the route between the microphone and the telephone line (sending) or between the telephone line and the speaker (receiving) where the signal disappears. Check the components at that point.

NO PULSE DIALLING

NO RINGTONE / NO BELL

NO TONE DIALLING

Power Supply Board Section. Key components for troubleshooting

Check the following parts first: F1, D10-D13, C5, and Q1. This comes from our experience with experimental tests. For example: power supply and lightning surge voltage test, withstanding voltage test, intentional short circuit test, etc.

Caution: If you find a melted fuse in the unit, donot turn on the power until you locate and repair the faulty parts (except for the fuse); otherwise the fuse will melt again and you cannot pinpoint the faulty point. In most cases, the symptom is that nothing is output. It is more likely that the fault is in the primary side rather than the secondary side. Check the primary side first.

TROUBLESHOOTING FLOWCHART

Broken Parts Repair Details

(D10, D11, D12, D13).

Check for a short-circuit in terminal 4. If D10, D11,D12 and D13 are short-circuits, F1 will melt (open). In this case, replace all of the parts (D10, D11, D12, D13, F1).

(Q1)

The worst case of Q1 is a short-circuit between the Drain and Gate because damage expands to the peripheral circuit of Q1. This is due to a very high voltage through the Gate circuit which is composed of R19, Q2, and Q21 etc. You should change all of the parts listed as follows. F1, Q1, R19, Q2, Q21

(D101, D104)

If D101 and D104 are broken, the oscillation circuit in the power supply cannot operate. Check it with an electric tester.

↧

ZENITH DVR-313 - POWER SUPPLY [SMPS] - Schematic (Circuit Diagram) - DVD RECORDER

↧

.jpg)