↧

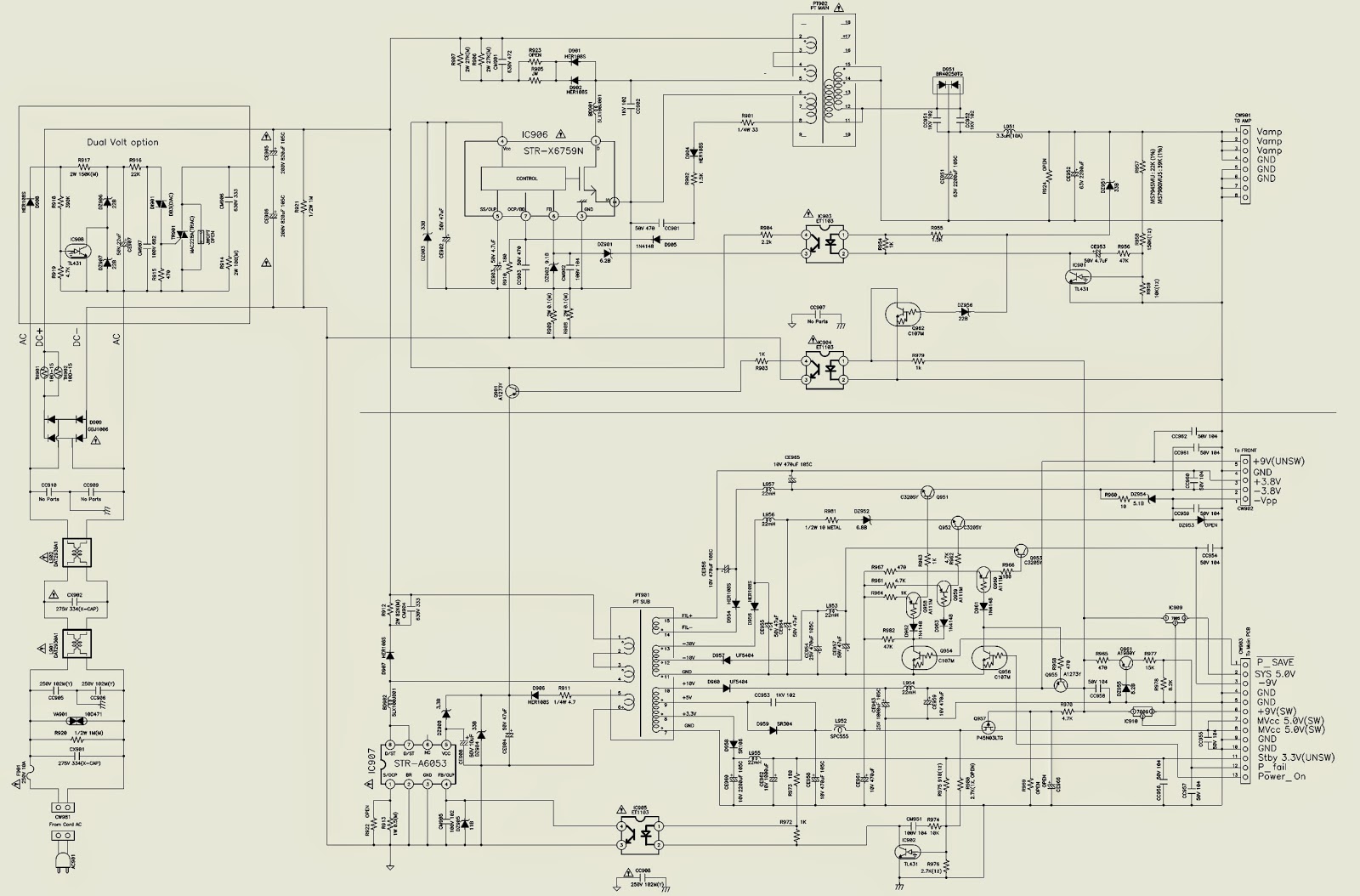

PIONEER X-HM20-K – CD RECEIVER SYSTEM – POWER and AMP CIRCUIT DIAGRAM

↧

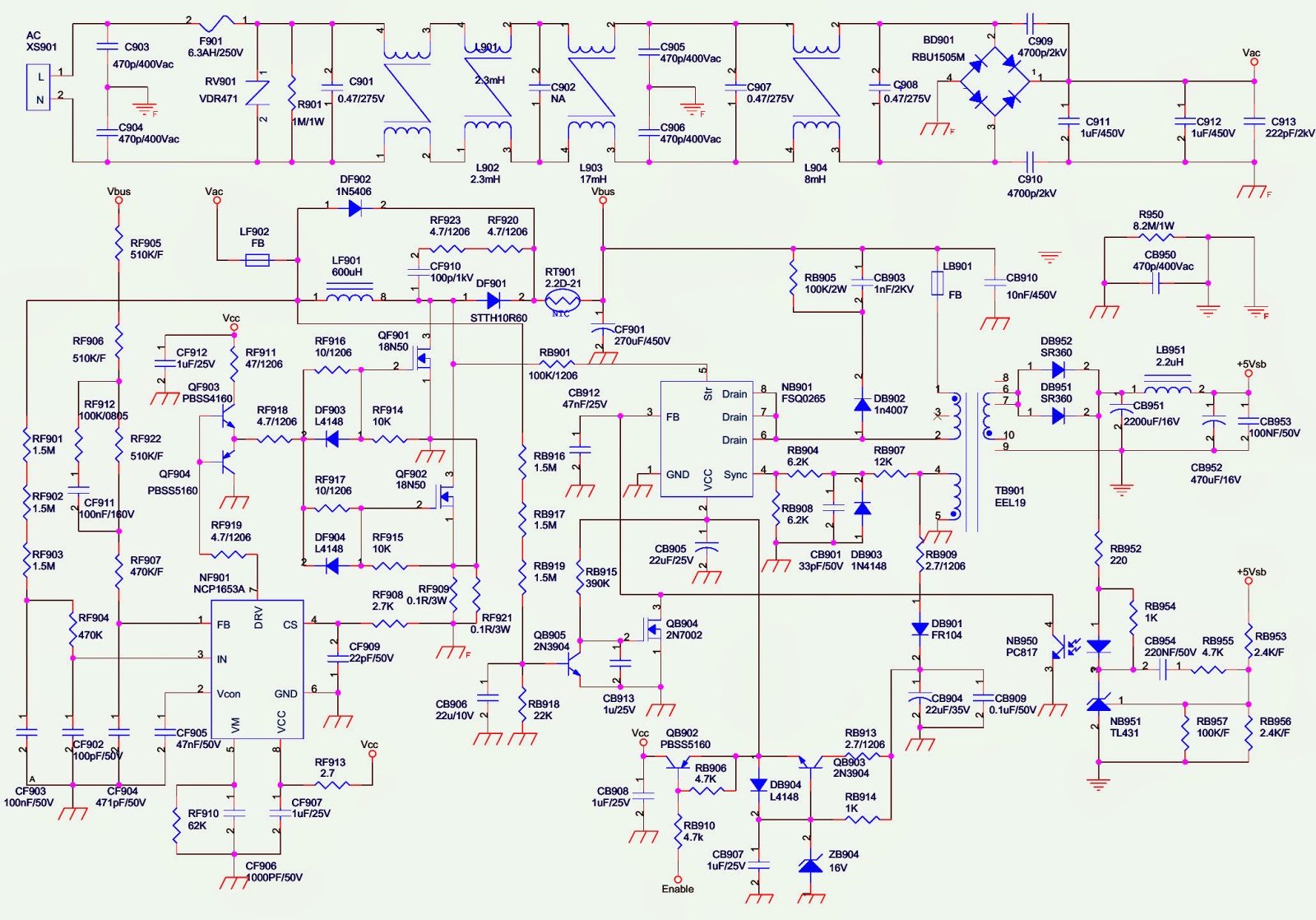

SERVICE MODE - DAYTEK LC2018NT Digital Flat Display - POWER SUPPLY SCHEMATIC

DAYTEK Digital Flat Display LC1508NT - LC1521NT - LC2018NT _ Service Mode_Power Supply Schematic_Universal Remote Control Set-up Codes

SERVICE MODE [Factory Mode]

SERVICE MODE [Factory Mode]

Enter factory mode adjustment using the remote control.

* Press Menu button once first

* Then press PRE.CH (or named RECALL) button five times, and you can see manufacture menu on the LCD panel.

* Press the Channel[ +/-] button to selection the sub menu of factory menu( including F, E, UOCⅢ, RGBTemp, Temp and press the Volume + to enter the sub menu and setting the value.

* Press the MUTE button again and again or turn off the TV, it can exit the factory menu.UNIVERSAL REMOTE CONTROL SET-UP CODES TO CHECK WITH DAYTEK TVs:

0194 0655 0658 0720

0194 0655 0658 0720

POWER SUPPLY SCHEMATIC {Click on the schematic to Zoom In}

↧

↧

LED BLINKING CODES - SERVICE MODE - SONY KP61V80 - COLOR REAR VIDEO PROJECTOR

SONY KP48V8 - KP53V80 - KP61V80 - COLOR REAR VIDEO PROJECTOR _ Self Diagnosis _ LED Blinking Codes _ Service Mode

KP48V8 _ RM-Y905 - KP53V80 _ RM-Y905 - KP61V80 _ RM-Y905

SUMMARY OF SELF-DIAGNOSIS FUNCTION

* This device includes a self-diagnosis function.

* In case of abnormalities, the TIMER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location by the number of blinks. The Instruction Manual describes blinking of the TIMER/STANDBY indicator.

* If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

* In case of abnormalities, the TIMER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location by the number of blinks. The Instruction Manual describes blinking of the TIMER/STANDBY indicator.

* If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

Diagnosis Items and Prediction of Malfunction Location

* When a malfunction occurs the TIMER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower blink count blinks first.

* The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunctions occurred.

* When a malfunction occurs the TIMER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower blink count blinks first.

* The screen display displays the results regarding all the diagnosis items listed below. The display “ 0 ” means that no malfunctions occurred.

{000 the range of values for number of operations is 000-255. For 256 or higher there is no count up and the number remains at 255.}

Blinking count display of TIMER/STANDBY indicator

[One blink is not used for self-diagnosis.]

Release of TIMER/STANDBY indicator blinking.

* The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch on the TV main unit or removing the plug from the power.

* The TIMER/STANDBY indicator blinking display is released by turning OFF the power switch on the TV main unit or removing the plug from the power.

Self-diagnosis screen displays

* In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the detection circuit operated or not) in order to allow confirmation.

* In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the detection circuit operated or not) in order to allow confirmation.

Screen Display Method

* Quickly press the remote command button in the following order from the standby state.

* Quickly press the remote command button in the following order from the standby state.

DISPLAY>CHANNEL (5)>VOL (--)>POWER.

Self-Diagnosis Screen Display

* The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure to return the results display to “ 0 ”.

* If the results display is not returned to “0 ” it will not be possible to judge a new malfunction after completing repairs.

* The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure to return the results display to “ 0 ”.

* If the results display is not returned to “0 ” it will not be possible to judge a new malfunction after completing repairs.

Method of Clearing Results Display

1. Power OFF [Set to standby state]

2. Press DISPLAY> CHANNEL (5)> VOLUME (+)> POWER{Service Mode}

3. Press CHANNEL (8) > ENTER [Test reset = Factory reset condition]

Method of Ending Self Diagnosis

When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit. Diagnosis Screen.

Self-diagnosis function operation

OCP>> Low B and +B line detect DET SHORT, and shut-down POWER ON RELAY.

Reset by turning power on/off.

In case of +B is loaded approx. 2A or more, microcomputer detects it via IC651.

OVP>> In case of +B becomes approx. 150V or more, POWER ON RELAY shuts down and microcomputer detects it via IC651.

Reset by turning power on/off just the same as OCP.

V Stop >> In case of microcomputer detects 2 seconds or more interval of V Pulse, Reference Pulse turns off by turning off the picture

signal in YC Jungle IC (IC206).

After the picture signal turns off, H Pulse is regenerated 2 seconds or more, the picture signal turns on.

AKB >> IK detection. Makes LED blinking in case of microcomputer doesn’t detect IK returns of IC206 CXA2147Q 30 seconds or more.

H Stop>> In case of HV becomes 33kV or more, IC502 detects it and shut-down H Drive Pulse.

Microcomputer receives H Stop data from IC206 and makes LED blinking.

Audio>> In case of DC component overlaps the output of Audio Amp., microcomputer detects it and makes LED blinking. Microcomputer forces to shut down the power.

OCP>> Low B and +B line detect DET SHORT, and shut-down POWER ON RELAY.

Reset by turning power on/off.

In case of +B is loaded approx. 2A or more, microcomputer detects it via IC651.

OVP>> In case of +B becomes approx. 150V or more, POWER ON RELAY shuts down and microcomputer detects it via IC651.

Reset by turning power on/off just the same as OCP.

V Stop >> In case of microcomputer detects 2 seconds or more interval of V Pulse, Reference Pulse turns off by turning off the picture

signal in YC Jungle IC (IC206).

After the picture signal turns off, H Pulse is regenerated 2 seconds or more, the picture signal turns on.

AKB >> IK detection. Makes LED blinking in case of microcomputer doesn’t detect IK returns of IC206 CXA2147Q 30 seconds or more.

H Stop>> In case of HV becomes 33kV or more, IC502 detects it and shut-down H Drive Pulse.

Microcomputer receives H Stop data from IC206 and makes LED blinking.

Audio>> In case of DC component overlaps the output of Audio Amp., microcomputer detects it and makes LED blinking. Microcomputer forces to shut down the power.

↧

FIRMWARE UPGRADE - REGION FREE - PHILCO PH-919 DVD PLAYER

How to make Region Free _ Philco PH-919 DVD Player _ Power Supply Circuit Diagram [Schematic]

Upgrading the System and Changing the Region Code

MTK upgrade:

* Name upgrade file as "MTK.BIN"(must be in big caps)

* Record it in a CD-R/W (It can be enclosed a sub-directory which size is about 30M, and the file content can be letter or non used file.) disc Format: (advise to use the tool NERO burning ROM)

Disc volume: MEDIATEK, ISO9660 LEVEL1, MODE1, not JOILET.

* Put the recorded disc into the DVD player, on the TV will show "upgrade?" after loading. Press PLAY button, the player will automatically upgrade.

* Do not shut down the player during upgrade, it will restart automatically after upgrade.

* Upgrade finish.

How to change the region code:

* Name upgrade file as "MTK.BIN"(must be in big caps)

* Record it in a CD-R/W (It can be enclosed a sub-directory which size is about 30M, and the file content can be letter or non used file.) disc Format: (advise to use the tool NERO burning ROM)

Disc volume: MEDIATEK, ISO9660 LEVEL1, MODE1, not JOILET.

* Put the recorded disc into the DVD player, on the TV will show "upgrade?" after loading. Press PLAY button, the player will automatically upgrade.

* Do not shut down the player during upgrade, it will restart automatically after upgrade.

* Upgrade finish.

How to change the region code:

This player uses NTSC/PAL color system. It cannot play discs recorded with other systems, such as SECAM.

The region code for this player is 5, which indicates the applicable. The disc with code number other than 5 cannot be player on this player and screen will indicate the unconformity.

* Power on the machine, and press OPEN button to push the tray out.

* Press SETUP button to enter the SETUP menu, and go to the PREFERENCE item by pressing left button, then press 5 buttons in turn: 4,9,5,4,0

* A edit box will be displayed, you can change the region code to 1-6 with UP/DOWN button, the num 0 means REGION FREE. And then press SETUP button to exit (FOR 1379)

* An item named VERSION will be displayed, you can change the region code to 1-6 with UP/DOWN button, the num (0) means REGION FREE. And then press SETUP button to exit (for 1369).

* Press SETUP button to enter the SETUP menu, and go to the PREFERENCE item by pressing left button, then press 5 buttons in turn: 4,9,5,4,0

* A edit box will be displayed, you can change the region code to 1-6 with UP/DOWN button, the num 0 means REGION FREE. And then press SETUP button to exit (FOR 1379)

* An item named VERSION will be displayed, you can change the region code to 1-6 with UP/DOWN button, the num (0) means REGION FREE. And then press SETUP button to exit (for 1369).

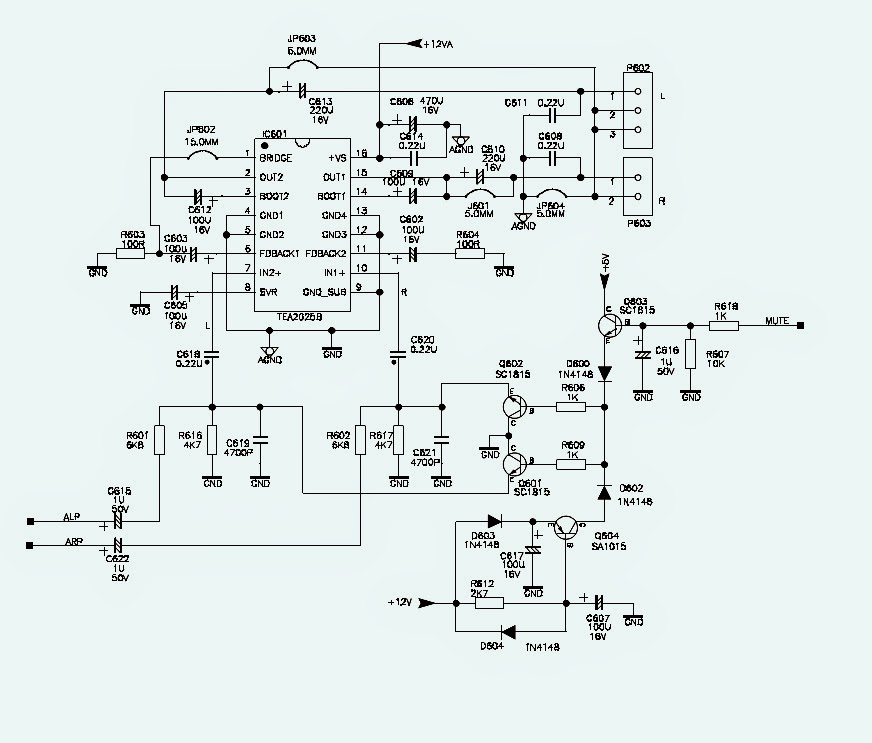

POWER SUPPLY REGULATOR [SMPS] SCHEMATIC

↧

HOW TO REPLACE OPTICAL ENGINE - WD62725 - MITSUBISHI PROJECTION TVs

MITSUBISHI WD-52525 - WD-52725 - WD-52825 - WD-62525 - WD-62725 - WD-62825

OPTICAL ENGINE REPLACEMENTOptical Engine Mounting

[The Optical Engine is mounted on the Adjuster assembly as shown below.]1. Four screws (a) secure the bottom plate and Optical Engine to the Adjuster assembly.

2. The bottom plate tab (1) slides into slot (1) on the Adjuster.

3. The Optical Engine is secured to the bottom plate by 4 screws (b).

4. The Black Bracket is secured to the bottom plate and the Lamp Box with 4 screws (c).

5. To replace the Optical Engine, the Optical Engine, bottom plate and black bracket need to be removed together as an assembly.

2. The bottom plate tab (1) slides into slot (1) on the Adjuster.

3. The Optical Engine is secured to the bottom plate by 4 screws (b).

4. The Black Bracket is secured to the bottom plate and the Lamp Box with 4 screws (c).

5. To replace the Optical Engine, the Optical Engine, bottom plate and black bracket need to be removed together as an assembly.

Removing the Optical Engine

1. Remove the Cabinet Back (refer to disassembly instructions).

2. Disconnect all connectors from the Optical Engine, Lamp Cartridge Housing and the PCB-DMD.

3. From the rear of the TV, remove the 4 screws (c), to remove the COVER-DUCT and DMD Fan cover.

4. From the rear of the TV, remove the 4 brass coloured screws (a), shown below, securing the bottom plate to the Adjuster assembly.

5. Slide the Optical Engine/Lamp Cartridge Housing towards the rear to remove from the TV.

1. Remove the Cabinet Back (refer to disassembly instructions).

2. Disconnect all connectors from the Optical Engine, Lamp Cartridge Housing and the PCB-DMD.

3. From the rear of the TV, remove the 4 screws (c), to remove the COVER-DUCT and DMD Fan cover.

4. From the rear of the TV, remove the 4 brass coloured screws (a), shown below, securing the bottom plate to the Adjuster assembly.

5. Slide the Optical Engine/Lamp Cartridge Housing towards the rear to remove from the TV.

Remove the following parts from the Optical Engine

* DMD Heat Sensor

* The Optical Engine bottom plate and black bracket

DMD Heat Sensor & Bottom Plate & Black Bracket Removal

1. Remove screw (a) on the top of the DMD Fan.

2. Set the Heat Sensor aside to install on the replacement Optical Engine.

* DMD Heat Sensor

* The Optical Engine bottom plate and black bracket

DMD Heat Sensor & Bottom Plate & Black Bracket Removal

1. Remove screw (a) on the top of the DMD Fan.

2. Set the Heat Sensor aside to install on the replacement Optical Engine.

Remove the 4 screws (B) from the Bottom Plate.

Remove the two screws (C), holding the Black Bracket to the Lamp Box.

Installing the Optical Engine

1. Install the Bottom Plate, Black Support Bracket and the Heat Sensor, removed from the original Optical

Engine, on the replacement Engine

2. Reverse the removal procedure to install the replacement Optical Engine in the cabinet.

3. The following adjustments may have to be performed after the installation.

* Horizontal and Vertical Electrical Centering Adjustment.

* Optical Unit Rotation Adjustment

* Optical Unit Keystone Distortion Adjustments.

4. IMPORTANT: After Optical Engine replacement, perform the Data Copy Procedure.

1. Install the Bottom Plate, Black Support Bracket and the Heat Sensor, removed from the original Optical

Engine, on the replacement Engine

2. Reverse the removal procedure to install the replacement Optical Engine in the cabinet.

3. The following adjustments may have to be performed after the installation.

* Horizontal and Vertical Electrical Centering Adjustment.

* Optical Unit Rotation Adjustment

* Optical Unit Keystone Distortion Adjustments.

4. IMPORTANT: After Optical Engine replacement, perform the Data Copy Procedure.

Data Copy Procedure

This procedure must be performed after replacing either the Electrical Chassis or Optical Engine.

1. To display the data copy menu press [TV MENU] [2-4-5-7] [0]

2. Use the cursor keys to yellow highlight “Copy Light Engine EEPROM to DM”

3. Press [ENTER]

4. After the copy procedure has been completed, exit the menu by pressing [HOME]

This procedure must be performed after replacing either the Electrical Chassis or Optical Engine.

1. To display the data copy menu press [TV MENU] [2-4-5-7] [0]

2. Use the cursor keys to yellow highlight “Copy Light Engine EEPROM to DM”

3. Press [ENTER]

4. After the copy procedure has been completed, exit the menu by pressing [HOME]

↧

↧

PHILCO [PHILIPS] - DVD PH-148 – RIPPING – POWER SUPPLY [SMPS] SCHEMATIC (Circuit Diagram)

↧

ERROR CODES - FRONT LED BLINKING CODES - ADJUSTMENTS - MITSUBISHI WD-52525 DLP TVs

WD-52525 _ WD-52725 _ WD-52825 _ WD-62525 _ WD-62725 _ WD-62825 DIGITAL LIGHT PROCESSING™ PROJECTION TVs

Universal Remote Control Set-up Codes

Universal Remote Control Set-up Codes

FRONT LED INDICATOR DIAGNOSIS

The front panel LEDs provide an indication of the sets operation, and the possible cause of a malfunction. There are three front panel LEDs, “Power”, “Status” and “Lamp”. Which LED is lit, the colour, and whether it is blinking or steady indicate the current status, or a possible malfunction.

Error Code Operational Check

Note: The TV must be in “Shut Down” and not manually switched Off, to perform the Error Code Operational Check. When the TV is switched Off, the code automatically resets to “12” No Error.

Press the front panel “DEVICE” and “MENU” buttons at the same time, and hold for 5 seconds to activate the Error Code Operational Check. The LED will then flash denoting a two digit Code.

Note: The front panel buttons must be used, NOT those on the Remote Control. • The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

Note: The TV must be in “Shut Down” and not manually switched Off, to perform the Error Code Operational Check. When the TV is switched Off, the code automatically resets to “12” No Error.

Press the front panel “DEVICE” and “MENU” buttons at the same time, and hold for 5 seconds to activate the Error Code Operational Check. The LED will then flash denoting a two digit Code.

Note: The front panel buttons must be used, NOT those on the Remote Control. • The number of flashes indicates the value of the MSD (tens digit) of the Error Code.

* The flashing then pauses for approximately 1/2 second.

* The LED then flashes indicating the value of the LSD (ones digit) of the Error Code.

Example: If the Error Code is “32”, the LED will flash three times, pause, and then flash two times.

Example: If the Error Code is “32”, the LED will flash three times, pause, and then flash two times.

The Error Code is repeated a total of 5 times.The Error Code designations are:

SERVICE ADJUSTMENTS

There are only 5 Service Adjustments required:

Two Electrical Adjustments

1. Horizontal Centering

2. Vertical Centering

Three Mechanical Adjustments

1. Picture Rotation

2. Horizontal Keystone Distortion

3. Vertical Keyst

Two Electrical Adjustments

1. Horizontal Centering

2. Vertical Centering

Three Mechanical Adjustments

1. Picture Rotation

2. Horizontal Keystone Distortion

3. Vertical Keyst

Circuit Adjustment Mode

On these models, the Circuit Adjustment Mode is used only for:

* Test Signal activation

* Horizontal Cantering

* Vertical Cantering one Distortion.

On these models, the Circuit Adjustment Mode is used only for:

* Test Signal activation

* Horizontal Cantering

* Vertical Cantering one Distortion.

Activating the Circuit Adjustment mode

1) Press the “TV MENU” button on the remote control. (The Customer Menu will appear.)

2) Press the buttons “2”, “4”, “5” and “7” in that order. (The screen will change to the adjustment mode.)

If unsuccessful, repeat steps 1 and 2.

2) Press the buttons “2”, “4”, “5” and “7” in that order. (The screen will change to the adjustment mode.)

If unsuccessful, repeat steps 1 and 2.

Test Signal Activation

When in the Circuit Adjustment mode, press “REWIND” once on the remote control to activate the test pattern. This pattern is used for both electrical and mechanical adjustments.

When in the Circuit Adjustment mode, press “REWIND” once on the remote control to activate the test pattern. This pattern is used for both electrical and mechanical adjustments.

Adjustment Function Selection

Use the “AUDIO” button to select a specific Adjustment Function.

Use the “AUDIO” button to select a specific Adjustment Function.

Adjusting Data

After selecting an adjustment item, use the UP and DOWN cursor buttons to change adjustment data.

* If the UP button is pressed, the adjustment data increases.

* If the DOWN button is pressed, the adjustment data decreases.

After selecting an adjustment item, use the UP and DOWN cursor buttons to change adjustment data.

* If the UP button is pressed, the adjustment data increases.

* If the DOWN button is pressed, the adjustment data decreases.

Saving data

* Press “ENTER” to save the adjustment data in memory. The display characters go red for about one second in this step. [If the circuit adjustment mode is terminated without pressing

“ENTER”, changes in adjustment data are not saved.]

* Press “ENTER” to save the adjustment data in memory. The display characters go red for about one second in this step. [If the circuit adjustment mode is terminated without pressing

“ENTER”, changes in adjustment data are not saved.]

Terminating the circuit adjustment mode

Press the “HOME button or the “MENU” button twice on the remote to terminate the adjustment mode. [The adjustment mode can be also terminated by turning the power off.]

Press the “HOME button or the “MENU” button twice on the remote to terminate the adjustment mode. [The adjustment mode can be also terminated by turning the power off.]

Resetting Data to Factory Values

1. Enter the Service Adjustment Mode ... Press “TV MENU” “2-4-5-7”

2. Press “0” when in the Service Mode ... Three choices appear at the top of the screen.

1. Enter the Service Adjustment Mode ... Press “TV MENU” “2-4-5-7”

2. Press “0” when in the Service Mode ... Three choices appear at the top of the screen.

Use UP & DOWN keys to highlight the desired choice, then Press “ENTER”

* Copy Light Engine EEPROM to DM ... required after replacing the Light Engine or Electrical Chassis.

* Restore Back Up ... resets Service Mode data back to factory values. Use this feature if service adjustment data has been corrupted or improper adjustments have been performed.

* Copy Light Engine EEPROM to DM ... required after replacing the Light Engine or Electrical Chassis.

* Restore Back Up ... resets Service Mode data back to factory values. Use this feature if service adjustment data has been corrupted or improper adjustments have been performed.

* Up Load Terminal Board Data ... uploads White Balance data from PWB-SIGNAL. (Do Not Select. This option is for depot level service only.)

Universal Remote Control Set-up codes to Mitsubishi brand TVs

Universal Remote Control Set-up codes to Mitsubishi brand TVs

0007 0013 0018 0049 0065 0101 0105 0119 0131 0152 0154 0161 0190 0209 0221 0247 0324 0454

CLICK ON THE PICTURES TO MAGNIFY

↧

HOW TO REPLACE LAMP BALLAST - DEFAULT SETTING VALUES - MITSUBISHI DLP PROJECTION TVs

Lamp ballast Removal – Lenticular screen & Fresnel lens – Initial set-up _ Default data values.

MITSUBISHI WD-52525 - WD-52725 - WD-52825 - WD-62525 - WD-62725 - WD-62825 -DIGITAL LIGHT PROCESSING [DLP] PROJECTION TV

To remove the chassis, the two connectors to the Lamp Ballast must be disconnected at the Lamp Ballast.

Accessing & Disconnecting the Lamp Ballast

Removing the Right Support

Remove the 3 screws shown.

Removing the Right Support

Remove the 3 screws shown.

SERVICING THE LENTICULAR SCREEN AND FRESNEL LENS

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens. This prevents cuts and finger prints. Do not place Fresnel Lens in the sun. This may cause fire and heat related injuries.

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens. This prevents cuts and finger prints. Do not place Fresnel Lens in the sun. This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1) Remove the screen assembly shown in the Cabinet Disassembly procedure.

2) Remove the four screws (a) to remove the bottom of the SCREEN-FRAME-BOTTOM .

3) Carefully slide the Lenticular Screen and Fresnel Lens combination from the Screen Frame assembly

Note:When separating the Lenticular Screen from the Fresnel Lens, use caution while prying the Screen and Lens apart. Use a slot type screw driver, and remove the pressure sensitive double sided tape.

1) Remove the screen assembly shown in the Cabinet Disassembly procedure.

2) Remove the four screws (a) to remove the bottom of the SCREEN-FRAME-BOTTOM .

3) Carefully slide the Lenticular Screen and Fresnel Lens combination from the Screen Frame assembly

Note:When separating the Lenticular Screen from the Fresnel Lens, use caution while prying the Screen and Lens apart. Use a slot type screw driver, and remove the pressure sensitive double sided tape.

Lenticular Screen and Fresnel Lens Installation

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High heat and humidity may deform the Lenticular Screen and Fresnel Lens.

1) Apply double coated tape (Part #LENS-TAPE) along the top rear edge of the Lenticular Screen, as shown.

2) Place the Fresnel Lens on top of the Lenticular Screen and apply pressure at the top edge to bond them together.

3) Reverse the Screen Removal procedure to insert the screens in the Screen Frame

Note: Store the Lenticular Screen and Fresnel Lens in a cool dry place. High heat and humidity may deform the Lenticular Screen and Fresnel Lens.

1) Apply double coated tape (Part #LENS-TAPE) along the top rear edge of the Lenticular Screen, as shown.

2) Place the Fresnel Lens on top of the Lenticular Screen and apply pressure at the top edge to bond them together.

3) Reverse the Screen Removal procedure to insert the screens in the Screen Frame

Assembly.

INITIAL SETUP: OPTION MENU

* Press the “MENU” button on the remote hand unit.

* Press the buttons “2”, “4”, “7” and “0” in order. (The screen will change to the option menu.)

* Press the buttons “2”, “4”, “7” and “0” in order. (The screen will change to the option menu.)

A/V Memory

Each of the external inputs has its own Audio/Video Memory. A change in an A/V setting at a specific input is stored in memory for that specific input.

A/V Reset

The AV Memory Reset in the user’s menu initializes the selected input’s A/V Memory.

Remote Control Operational Modes

There are two Remote Hand Unit Operational Modes, “Standard” and “Net Command”. The Remote is initially in the “Standard” mode. The “Net Command” mode is used when controlling Home theater devices using Net Command.

Each of the external inputs has its own Audio/Video Memory. A change in an A/V setting at a specific input is stored in memory for that specific input.

A/V Reset

The AV Memory Reset in the user’s menu initializes the selected input’s A/V Memory.

Remote Control Operational Modes

There are two Remote Hand Unit Operational Modes, “Standard” and “Net Command”. The Remote is initially in the “Standard” mode. The “Net Command” mode is used when controlling Home theater devices using Net Command.

To change the Remote Operational Mode

* Set the Remote to the TV Layer • Point the Remote away from the TV. • To change to “Netcommand” ... Hold the “Power” button and press “9-3-5” in sequence.

* Set the Remote to the TV Layer • Point the Remote away from the TV. • To change to “Netcommand” ... Hold the “Power” button and press “9-3-5” in sequence.

* To change to “Standard” ... Hold the “Power” button and press “0-0-0” in sequence.

CLICK ON THE PICTURES TO ZOOM IN

↧

SONY KDS-R50XBR1- KDS-R60XBR1 - LED BLINKING CODES - LAMP REPLACEMENT

SONY - KDS-R50XBR1- KDS-R60XBR1 [RM-Y914 USA & Canada] - SXRD PROJECTION TV

Lamp Replacement_lamp time reset_LED blinking codes_Self Diagnosis

Universal Remote Control Set-up Codes

LAMP REPLACEMENT* Turn off the power on the main unit. Wait several minutes, then unplug the power cord. (The cooling fan will continue to operate for about two minutes after turning the power off.)

* Wait at least 30 minutes after unplugging the power cord to allow the lamp to cool down before replacing it. To avoid being burned, do not touch the lamp receptacle once the lamp has been removed.

* Take the new lamp out of its package. Turn the screw with a screwdriver ccounter-clockwiseand remove the outside lamp cover. Pull out the lamp. Place your index finger through the hoop of the lamp handle and pull it upwards, while placing your thumb on the dent on the top. Then pull the lamp out.

* Wait at least 30 minutes after unplugging the power cord to allow the lamp to cool down before replacing it. To avoid being burned, do not touch the lamp receptacle once the lamp has been removed.

* Take the new lamp out of its package. Turn the screw with a screwdriver ccounter-clockwiseand remove the outside lamp cover. Pull out the lamp. Place your index finger through the hoop of the lamp handle and pull it upwards, while placing your thumb on the dent on the top. Then pull the lamp out.

* Place the lamp halfway in. Follow the gutter in the compartment to mount the new lamp securely.

Slide it in slowly by pressing the [PUSH] part of the front corners of the lamp until it stops with a firm clicking sound to lock.

* Place the outside lamp cover back in its place. Turn the screw with a screwdriver clockwise and secure the cover. [This product contains mercury. Disposal of this product may be regulated if sold in the United States. Do not leave the used lamp near flammable materials or within the reach of children. Do not pour water onto the used lamp or put any object inside the lamp. Doing so may cause the lamp to burst.]

To read Lamp and Panel time

The lamp and panel time of the set are displayed as follows.

The lamp and panel time of the set are displayed as follows.

Enter the service mode

* Press the keys of the remote commander in rapid sequence as follows, when the set is in standby mode.

* Press the keys of the remote commander in rapid sequence as follows, when the set is in standby mode.

DISPLAY> CHANNEL (5)> VOLUME (+)> POWER

* Press the “JUMP” key [3 times]. You’ll get into DE-micro service menu .* Press “2” key [9 times] to show the following display.

PANEL NVM OK 9 OPTION_E

0 LAMP 0 Diff 1

LampTM 14 LampCT 71

0 LAMP 0 Diff 1

LampTM 14 LampCT 71

This screen reads

“Total lamp time is 14 hours” and “Total lamp ON/OFF cycle is 71 times”

>> To reset lamp time, press “3”,“MUTE” and “ENTER” keys in sequence. WRI-EXE (Red Character) is momentarily displayed and LampTM will be reset to “0 ”

* Press “1” key [7 times].

“Total lamp time is 14 hours” and “Total lamp ON/OFF cycle is 71 times”

>> To reset lamp time, press “3”,“MUTE” and “ENTER” keys in sequence. WRI-EXE (Red Character) is momentarily displayed and LampTM will be reset to “0 ”

* Press “1” key [7 times].

PANEL NVM OK 9 OPTION_E

7 SH SFT1 10 Diff 1

PanelTM 14h

7 SH SFT1 10 Diff 1

PanelTM 14h

This screen reads

"Total Panel time is 14 hours”

{You can’t reset the Panel time with the Service menu.}

{You can’t reset the Panel time with the Service menu.}

To get out of the Service menu

The Service menu is cleared by turning off the set with a remote commander or the power switch.

The Service menu is cleared by turning off the set with a remote commander or the power switch.

Test Reset

The user settings can be reset to the factory default condition as follows.

Press “TEST “ and “RESET “ key in sequence when the set is ON . The LAMP, TIMER and POWER/STANDBY LED light and the picture is muted. After about 5 seconds the LAMP and TIMER LED go off, and the colour of POWER/STANDBY LED changes from amber to green.After another 10 seconds the reset is completed and the initial set-up display appears.

The user settings can be reset to the factory default condition as follows.

Press “TEST “ and “RESET “ key in sequence when the set is ON . The LAMP, TIMER and POWER/STANDBY LED light and the picture is muted. After about 5 seconds the LAMP and TIMER LED go off, and the colour of POWER/STANDBY LED changes from amber to green.After another 10 seconds the reset is completed and the initial set-up display appears.

Self-Diagnosis Function

This device includes a self-diagnosis function.

In case of abnormalities, the POWER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location by the number of blinks. The Instruction Manual describes blinking of the POWER/STANDBY indicator.

If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

This device includes a self-diagnosis function.

In case of abnormalities, the POWER/STANDBY indicator automatically blinks. It is possible to predict the abnormality location by the number of blinks. The Instruction Manual describes blinking of the POWER/STANDBY indicator.

If the symptom is not reproduced sometimes in case of a malfunction, there is recording of whether a malfunction was generated or not. Operate the remote command to confirm the matter on the screen and to predict the location of the abnormality.

Diagnosis Items and Prediction of Malfunction Location

When a malfunction occurs the POWER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower blink count blinks first. The screen display displays the results regarding all the diagnosis items listed below. The display "0" means that no malfunctions occurred.

When a malfunction occurs the POWER/STANDBY indicator only blinks for one of the following diagnosis items. In case of two or more malfunctions, the item which first occurred blinks. If the malfunctions occurred simultaneously, the item with the lower blink count blinks first. The screen display displays the results regarding all the diagnosis items listed below. The display "0" means that no malfunctions occurred.

To Release of POWER/STANDBY indicator blinking

The POWER/STANDBY indicator blinking display is released by removing the plug from the power or leaving for 2 minutes.

The POWER/STANDBY indicator blinking display is released by removing the plug from the power or leaving for 2 minutes.

Self-diagnosis screen displays

In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the detection circuit operated or not) in order to allow confirmation.

In cases of malfunctions where it is not possible to determine the symptom such as when the power goes off occasionally or when the screen disappears occasionally, there is a screen display on whether the malfunction occurred or not in the past (and whether the detection circuit operated or not) in order to allow confirmation.

Screen Display Method

Quickly press the remote command button in the following order from the standby state.

Quickly press the remote command button in the following order from the standby state.

DISPLAY>CHANNEL (5) >VOLUME (--)>POWER

# Numeral "1" means a fault was detected one time.

# Numeral "0" means that no fault was detected.

# Numeral "0" means that no fault was detected.

The results display is not automatically cleared. In case of repairs and after repairs, check the self-diagnosis screen and be sure to return the results display to "0".

If the results display is not returned to "0" it will not be possible to judge a new malfunction after completing repairs.

If the results display is not returned to "0" it will not be possible to judge a new malfunction after completing repairs.

Method of Ending the Self-Diagnosis Screen

When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

When ending the self-diagnosis screen completely, turn the power switch OFF on the remote commander or the main unit.

Self-Diagnosis function operation

2) Temp >> When the temperature sensor (for Ambient) on the S1 board detects high temperature or the temperature sensor (for Lamp) on the S2 board detects high temperature or the temperature sensor (for Panel) on the C board detects high temperature, the DE-micro (IC5) turns off the lamp.

3) Lamp cover >> The rib at the back of the lamp cover closes the SW on the T1 board. The lamp closes the SW on the T2 board. It is monitored by DE-micro (pin63 of IC5) and turned off the lamp when it is opened.

4) Fan >> Fan rotation is detected by ‘‘FAN-PROT” and the DE-micro (pin92 of IC5) turns off the lamp when it is ‘‘high”.

5) Lamp Driver >> When the ‘‘LAMP-PROT” (pin83 of IC5) is high, the lamp is not turned on. If the ‘‘LAMP-HV-DET” (pin94 of IC5) is low at the same time, it classified as no high voltage of the lamp driver.

6) Low B error >> When no ‘‘D5V (SW_5V)” is detected, pin 129 of TV-micro (IC7002) is low and it turns off the main power. (for example, blowout of thermal fuse).

7) Audio >> When DC voltage is detected at the speaker output, ‘‘SP-PROT” (pin102 of IC5) is low and it turns off the main power.

8) D-OVP >> Be not in use.

9) Panel error >> When there is no track from the temperature sensor on the S1, S2 and C board or IIC line connector (CN2303: ASU board, CN7956: DSU board, CN6901: C board) is not seated securely. It is monitored by DE-micro.

10) ATSC-OVP >> Be not in use.

(LAMP) - Lamp >> When the ‘‘LAMP-PROT” (pin83 of IC5) is high, the lamp is not turned on. If the ‘‘LAMP-HV-DET” (pin94 of IC5) is high at the same time, it classified as no lamp or a dead lamp.

Universal remote control set-up codes to Sony Brand TVs.

0018 0045 0101 0131 0154 0177 0211 0301 0302 0357 0358 0609 0785

↧

↧

LG 32LW5700 - 32" LED LCD TV - VIDEO FAULTS - TROUBLESHOOTING

Video Errors & Troubleshooting procedure _ LG 32LW5700 { 32" LED LCD TV} North/Latin America _ Europe/Africa _ Asia/Oceania

Universal Remote Control Set--up Code list

VIDEO ERROR_VIDEO LAG / STOPUniversal Remote Control Set--up Code list

Checking part: TUNER

Checking method:* Check the signal strength or check whether the screen is normal when the external device is connected.

* After measuring each voltage from power supply, finally replace the MAIN BOARD.

PSU [Power Supply Unit] _Voltage Details

* After measuring each voltage from power supply, finally replace the MAIN BOARD.

PSU [Power Supply Unit] _Voltage Details

COLOUR ERROR

Adjustment Test pattern - ADJ Key (You should have a Service Remote Control to adjust all the service adjustments. Service remote control can be bought from the authorized service centre.)

You can view 6 types of patterns using the ADJ Key

Checking item :

Checking item :

1) Defective pixel

2) Residual image

3) MODULE error (ADD-BAR,SCAN BAR..)

4) Video error (Classification of MODULE or Main-B/D)

4) Video error (Classification of MODULE or Main-B/D)

PSU (LED driver) Faults [In these cases; exchange the PSU (Power Supply Unit)]

Exchange the Module { Un-repairable Cases. In these cases, module should be exchanged.}

CLICK ON THE PICTURES TO MAGNIFY

Universal Remote Control Set-up Codes

LG(GOLDSTAR)_ 0011 0025 0049 0050 0054 0055 0101 0107 0110 0119 0152 0165 0166 0168 0181 0182 0195 0235 0250 0303 0379 0380 0414 0421 0433 0460 0465 0611 0613 0658

↧

HOW TO DISASSEMBLE SONY KDS-R50XBR - SONY KDS-R60XBR - PROJECTION TVs

Disassemble Procedure to Sony KDS-R50XBR1_Sony KDS-R60XBR1_Projection TVs.

REAR COVER REMOVAL

REAR COVER REMOVAL

CLICK ON THE PICTURES TO MAGNIFY

TERMIANAL BRACKET & SERVICE POSITION

POD BLOCK ASSEMBLEY & ANTENNA SWITCH

DC MOTOR SFF21C /C-NP & POWER SUPPLY PACK

UNIT COVER ASSEMBLY; LAMP (R) GUIDE ASSEMBLEY & DC MOTOR SFF22A/C-NP

OPTIC BLOCK ASSEMBLY & SCREEN FRAME BLOCK ASSEMBLY

MIRROR COVER BLOCK ASSEMBLY

↧

TOSHIBA MS 7945 – MS7960 - MINI SYSTEM AM/FM STEREO - SCHEMATIC (Circuit Diagram)

Toshiba MS 7945 – MS7960 - MINI SYSTEM AM/FM STEREO, BLUETOOTH, CD, MP3, USB - CD RIP – SUBWOOFER

SMPS_Amp_CD Servo _ CD-DSP - Circuit Diagrams

SMPS_Amp_CD Servo _ CD-DSP - Circuit Diagrams

Used ICs STA517B_BU9543KV_SA5888_A3V64S40ETP_BU4094BCF_MBL0402F25K16PA-100PAG_M74HC157TTR_HT1381_MLC3895

POWER SUPPLY [SMPS]

POWER SUPPLY [SMPS]

AMPLIFIER

CD-SERVO

CD-DSP

CLICK ON THE SCHEMATICS TO MAGNIFY

↧

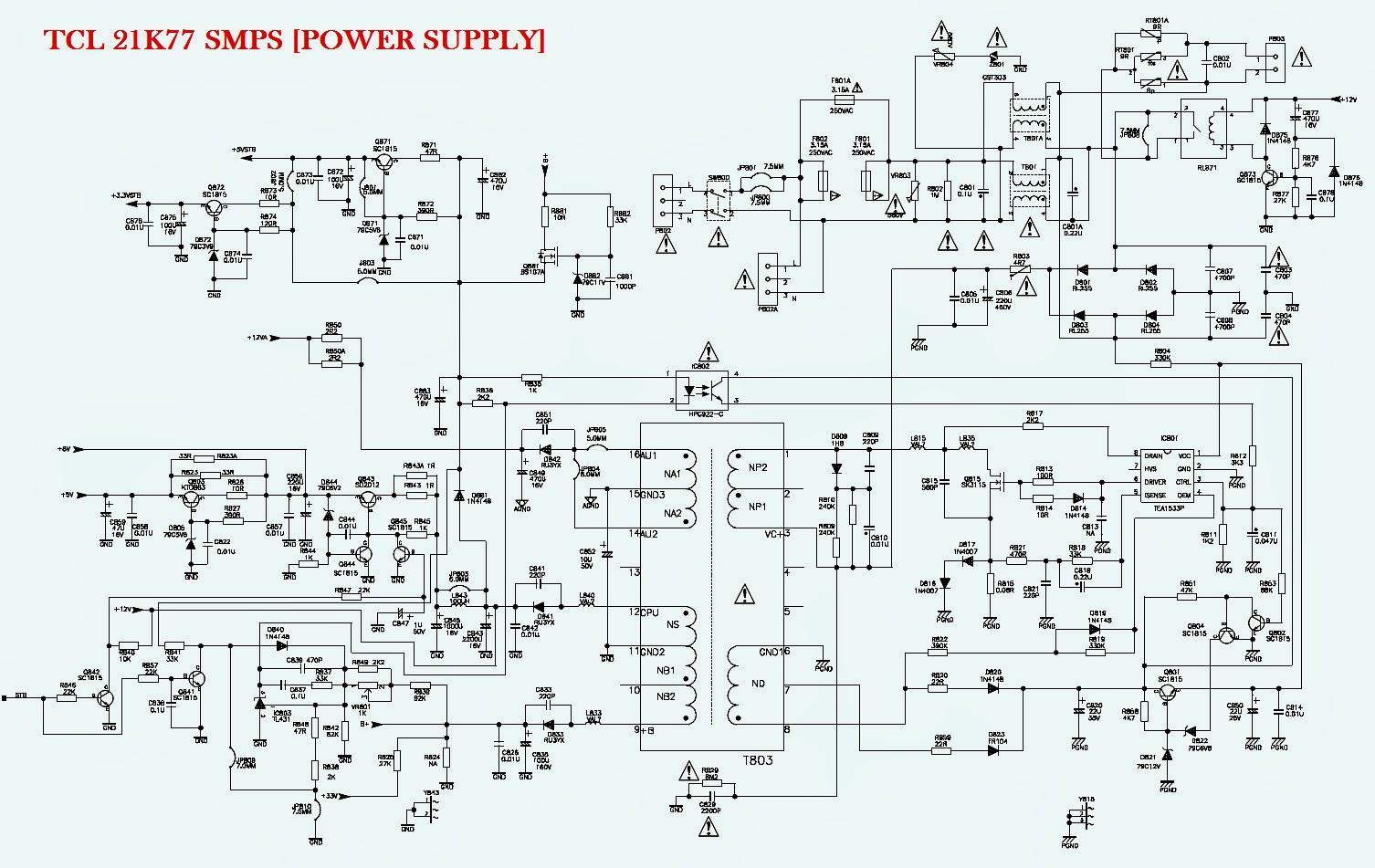

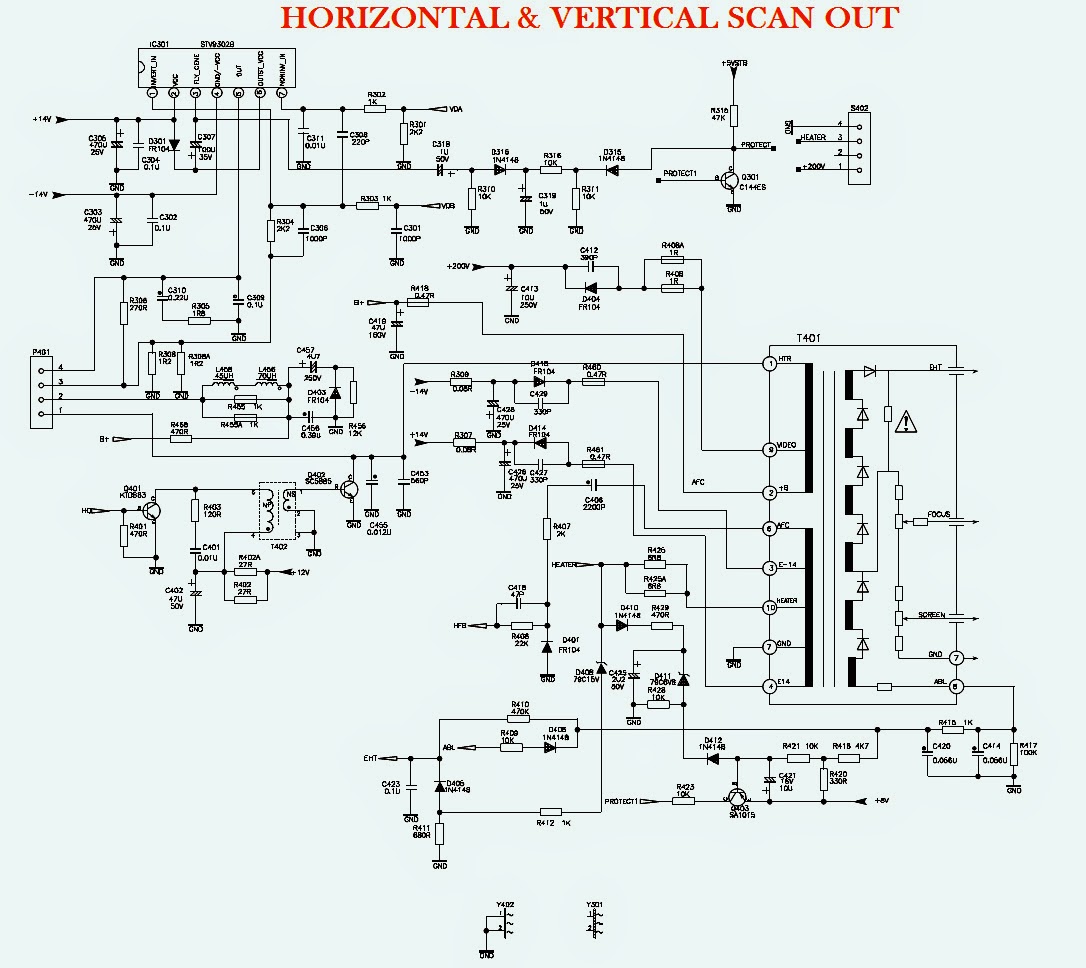

21K77 - TCL CRT TV - SCHEMATIC [Circuit Diagram)

↧

↧

KONKA KIPL072U04C2-01 – KPS300-1 _ SCHEMATIC [CIRCUIT DIAGRAM]

KONKA LCD KIPL072U04C2-01 SMPS & Back-light Inverter &KONKA- KPS300 SMPS Schematics

USED SEMICONDUCTORS - NCP1653A_FSQ0265_18N50(FET)_FSQ0765_UBA2702(Back-light Inverter Controller)

USED SEMICONDUCTORS - NCP1653A_FSQ0265_18N50(FET)_FSQ0765_UBA2702(Back-light Inverter Controller)

{Universal Remote Control Set-up Codes}

KIPL072U04C2-01 Back-light Inverter

CLICK ON THE SCHEMATICS TO MAGNIFY

Universal Remote Control Set-up codes to check with Konka Brand TVs [for both CRT & LCD types]0049 0101 0123 0152 0163 0214 0225 0252 0460 0637 0647 0674 0679

↧

HOW TO ENTER SERVICE MODE - HYUNDAI H-TV2910 - V-CHIP UNLOCK - MASTER PASSWORD

Service Mode [Factory Mode]_V-Chip unlock_Universal Remote Control Set-up Codes_Circuit Diagram-Full

Used ICs: LA72700_LA76933_LA78041_AT24C08 TC4053BP_LV116N__LA76938_LM2052

Universal Remote Control Set-up Codes

TO CHANGE THE PASSWORDFollow the same steps as the setting up new password. It must be in OFF mode of the V-CHIP function.

MASTER PASSWORD

If you turn on the V-Chip function but failed to remember the password, you can enter the Master Password 1980 to enter into the V-Chip menu.

MPAA RATING

The MPAA film rating system is a system used in the United States and territories and instituted by the Motion Picture Association of America to rate a movie based on its content, being used to decide which movies may be appropriate for children and/or adolescents.

The current MPAA move ratings consist of:

Rated G General Audiences

* Rated PG Parental guidance suggested

* Rated PG-13 Parents strongly cautioned

* Rated R Restricted. Under 17 requires accompanying parent or legal guardian.

* Rated NC-17 & X No 17 and under admitted. Also called Youth Restricted Viewing.

Rated G General Audiences

* Rated PG Parental guidance suggested

* Rated PG-13 Parents strongly cautioned

* Rated R Restricted. Under 17 requires accompanying parent or legal guardian.

* Rated NC-17 & X No 17 and under admitted. Also called Youth Restricted Viewing.

# Press the V-Chip button to go to the MPAA Rating menu.

# Press . +/- and Menu buttons to select.

# Press the V-Chip button again to return.

# Press the V-Chip button again to return.

CAN.ENG-RATING(Option)

For Canadian English language Rating System, the following seven

Ratings are available.

E : Exempt

For Canadian English language Rating System, the following seven

Ratings are available.

E : Exempt

C : Children

C8 : Children eight years and older

G : General programming, suitable for all audiences

PG : Parental Guidance

14 : Viewers 14 years and older

18 : Adult Programming

Select each item by the PROG.+/- buttons, confirm each item the MENU Buttons.

C8 : Children eight years and older

G : General programming, suitable for all audiences

PG : Parental Guidance

14 : Viewers 14 years and older

18 : Adult Programming

Select each item by the PROG.+/- buttons, confirm each item the MENU Buttons.

CAN.FRN-RATING (Optional)

EG:Exempt

G: General

8A:General -Not recommended for youngchildren

13A: Thisissuancemay not be suitablefor children under13 years

16A: Thisissuanceis not suitable forunder 16

18A: Thisissuanceisreserved foradults

EG:Exempt

G: General

8A:General -Not recommended for youngchildren

13A: Thisissuancemay not be suitablefor children under13 years

16A: Thisissuanceis not suitable forunder 16

18A: Thisissuanceisreserved foradults

Factory mode [Service Mode]

>> Press “Prod” key to enter the factory menu.

>> Select item by [Prog +] & “Prog [ – ] keys.

>> Adjust the data values by [Vol + ] & [Vol --] keys.

>> Press the “Prod” key to Exit the factory mode.

SCHEMATIC DIAGRAM

CLICK ON THE SCHEMATICS TO ZOOM IN

Universal Remote Control Set-up Cods to Hyundai TVs

0025 0031 0101 0194 0658 0673 0680 0697 0758 0777 0791 0798

↧

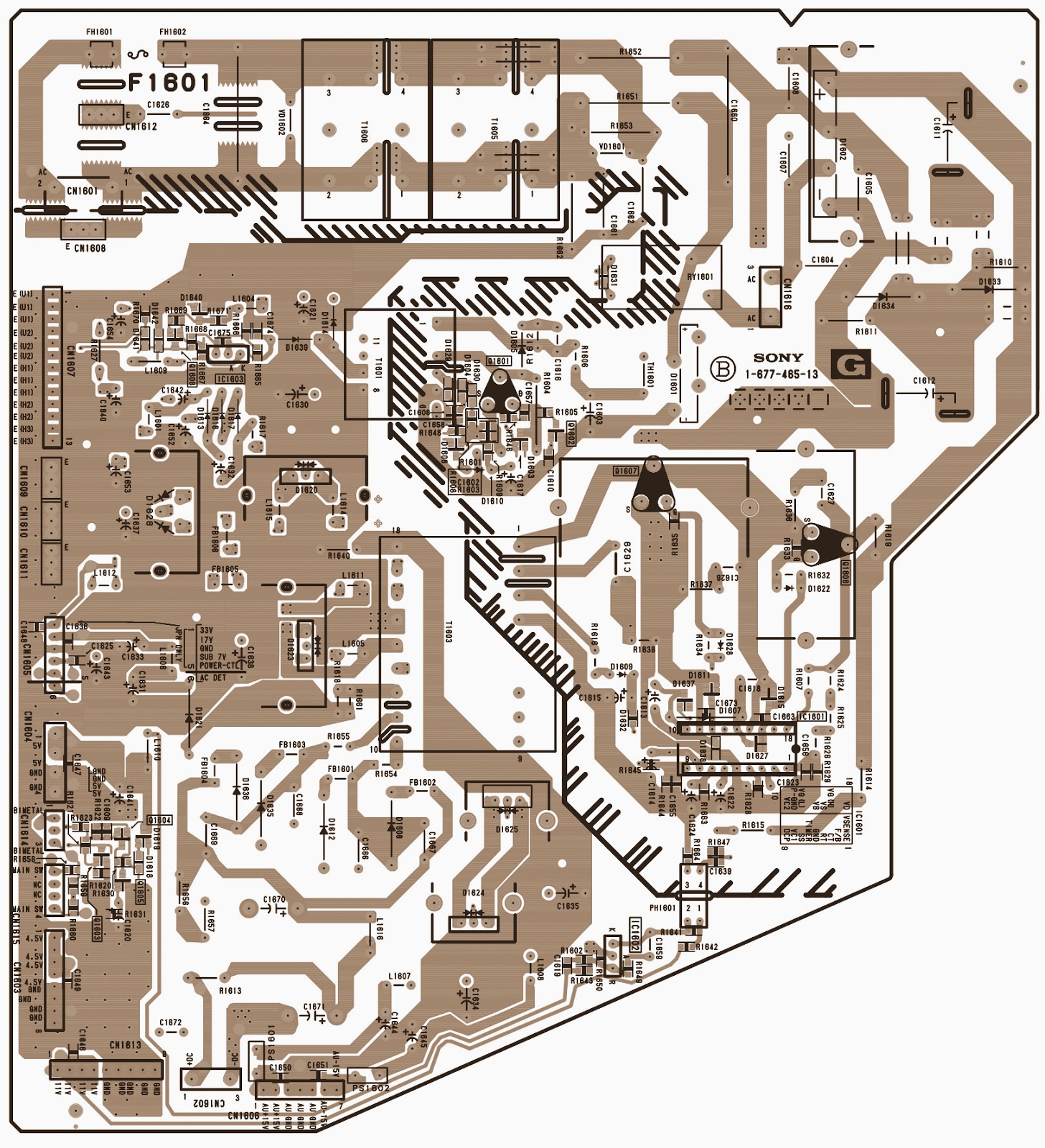

HYUNDAI H-LCD2601 _ SERVICE MODE - POWER SCHEMATIC

H-LCD2601_HYUNDAI LCD TV_FACTORY MODE_KEY COMPONENTS_Fault Symptoms & corrections_Power Supply [SMPS] Schematic (Circuit Diagram)

KEY COMPONENTS AND PART NUMBERSCHD-W320F8

Built-in power supply module > FSP179-4F01

Electronic tuner > TMI4-C22P2RW or TAD5-C2IP1RW

Electric speaker > Y2929-01-5W-8Ω or Y50138-01-8W-8Ω

Remote controller > KLC5B

Main board assembly - LG screen > JUJ6.690.035 _ PCB JUJ7.820.088

Main board assembly - SAMSUNG screen > JUJ6.690.035-4 _ PCB JUJ7.820.088

Built-in power supply module > LC320W01 - LG screen

LCD display screen > LTA320W02-L01 - SAMSUNG screen

Electronic tuner > TMI4-C22P2RW/ TAD5-C2IP1RW

Electric speaker > Y2929-01-5W-8Ω/ Y50138-01-8W-8Ω

Remote controller > KLC5BCHD-W370F8

Main board assembly > JUJ6.690.035-9 - PCB JUJ7.820.088

LCD display screen > LC370W01

Suspending screen > TMI4-C22P2RW

Electronic tuner > TMI4-C22P2RW | TAD5-C2IP1RW

Electric speaker > Y3297-R-10W-8Ω | Y3939-01-5W-8Ω

Remote controller > KLC5BSymptoms and Correction

The display boards of PC no image in DVI.

Reason and Resolve: If some display board of DVI cannot receive the data when turning on the TV, there is no output; if pull out the DVI line abruptly, there is also no DVI output; Before starting PC, connect the DVI line with LCD TV steadily, So DVI can receive the correct date from DDC Display

Data Channel when turning on the TV,DDC is in chassis 24LC21.

Reason and Resolve: If some display board of DVI cannot receive the data when turning on the TV, there is no output; if pull out the DVI line abruptly, there is also no DVI output; Before starting PC, connect the DVI line with LCD TV steadily, So DVI can receive the correct date from DDC Display

Data Channel when turning on the TV,DDC is in chassis 24LC21.

No picture but sound, on LOGO when turning on the TV, poor light is bright.

Reason and Resolve: Check the connect line in up screen, and connect the line

Reason and Resolve: Check the connect line in up screen, and connect the line

No picture no sound ,no snowflake in TV condition, but AV is normal.

Reason and Resolve: Check the outside of RF(also bus and power supply), there is no problem ,but no output from RF, so the RF is disabled.

Reason and Resolve: Check the outside of RF(also bus and power supply), there is no problem ,but no output from RF, so the RF is disabled.

LCD TV cannot be controlled.(inc red lamp is no but the TV is off, remote control and key press in TV cannot control the TV etc.)

Reason and Resolve: The LCD TV cannot work abruptly, power off and turning it on again.

Reason and Resolve: The LCD TV cannot work abruptly, power off and turning it on again.

Enter into factory menu

* Enter into child lock of main menu in TV mode, press “OK, the password input box will appear

* Use remote control to input the follows in order: (7 | red key | 9 | blue key) then you can enter into factory mode menu. After entering into factory mode menu, sign of the factory menu M will appear.

* Enter into child lock of main menu in TV mode, press “OK, the password input box will appear

* Use remote control to input the follows in order: (7 | red key | 9 | blue key) then you can enter into factory mode menu. After entering into factory mode menu, sign of the factory menu M will appear.

Factory menu display.

M

M

Index: 1

HWUC_BRI 0x1F

The M denotes entering into factory mode now, the figures of index denotes the index number now, the HWUC_BRI denotes the name of adjusting item now, the 0X1F denotes the numerical value.

HWUC_BRI 0x1F

The M denotes entering into factory mode now, the figures of index denotes the index number now, the HWUC_BRI denotes the name of adjusting item now, the 0X1F denotes the numerical value.

Each adjusting item have only one index number, the operator press the numeric key or press P+/P- directly.

Adjustment methods for factory menu

Select the adjusting item.

Select the adjusting item.

You can skip to the adjusting items by pressing the number key, also can select the adjusting item in the order of P+/P-.

When pressing the number key, if the adjusting item is 1~9,input the corresponding number keys and press down “OK”.

If the adjusting items tens digit, input a tens digit. (For example ,press number key 8 when adjusting the volume, you can see the colour which become green, then press down “OK”, the colour of index number turns red, So you already selected corresponding volume adjusting item. If adjust DVD pre-set, first input 1,then input 3,you can adjust DVD pre-set.)

Adjustment methods

Adjust it according to the operating key in above list. For one acting operation, press OK/V+. [Example Auto Colour, for some variable add/reduce, Example Volume, press V+/V- .]

Adjust it according to the operating key in above list. For one acting operation, press OK/V+. [Example Auto Colour, for some variable add/reduce, Example Volume, press V+/V- .]

The illuminate of white balance and Auto Color adjustment method

Press “OK” or “V+”,appear corresponding three variable, press “P+/P-”to select, press “V+/V-”,press down menu key to exit.

The index of Auto Colour is 12,press “OK” or “V+” to do colour revise, then the adjusted value will display.

Press “OK” or “V+”,appear corresponding three variable, press “P+/P-”to select, press “V+/V-”,press down menu key to exit.

The index of Auto Colour is 12,press “OK” or “V+” to do colour revise, then the adjusted value will display.

SMPS SCHEMATIC[Click on the Schematic to Magnify]

↧

PHILIPS AZ1134 – MP3 – CD Sound machine _ Schematic [Circuit diagram]

↧

↧

SONY 50SX100U LCD PROJECTION TV - ERROR CODES - LED BLINKING CODES

SONY KF-50SX100- KF50SX100K - KF/50SX100U LCD PROJECTION TV

SELF DIAGNOSTIC – BLINKING CODES – ERROR CODES

SPECS:

The identification of errors is triggered in one of two ways.

TV System B / G / H,D / K,I,L

Colour System

PAL, SECAM \NTSC3.58, 4.43 (Video IN only)

Channel Coverage

VHF > E2 ~ E12

UHF > E21~E69

CATV >S1~S20

HYPER > S21~S41

D /K > R-1~R12, R11~R69

I > UHF B21~B69

L > F2~F10, B-Q, F21~F69The identification of errors is triggered in one of two ways.

1) Busy or

2) Device failure to respond to IIC. In the event of one of these situations arising the software will first try to release the bus if busy (Failure to do so will report with continuous flashing LED) and then communicate with each device in turn to establish if a device is faulty. If a device is found to be faulty the relevant device number will be displayed through the LED (Series of flashes which must be counted) , non fatal errors are reported using this method.

BLINKING CODES

ERROR DETECTION MONITOR

Device acknowledges is used to check IIC errors. Each device is checked three times, if there is no acknowledge after every attempt, it will be regarded as an error. There are three step to check errors.

IIC line 0: If all devices except the NVM have errors, IIC line 0 errors are displayed.

Each device check: if IIC line error and board error are not detected then the device with an error is displayed.

Each device check: if IIC line error and board error are not detected then the device with an error is displayed.

The detected errors can be displayed as follows:

1) Error Monitor Menu

2) Error Reader

1) Error Monitor Menu

2) Error Reader

Error Monitor Menu

The error monitor menu is displayed by selecting Service mode : Monitoring. The following menu will be displayed.

The error monitor menu is displayed by selecting Service mode : Monitoring. The following menu will be displayed.

Error Reader Display

The error reader display is connected to the service connector to read actual error codes. The part number for the error reader display is S-188-900-10. Once an error has been detected it will then be displayed on the two digit error reader. The errors displayed refer to the following table

The error reader display is connected to the service connector to read actual error codes. The part number for the error reader display is S-188-900-10. Once an error has been detected it will then be displayed on the two digit error reader. The errors displayed refer to the following table

CLICK ON THE TABLES TO ZOOM IN

↧

POWER SUPPLY - G-BOARD - SCHEMATIC (Circuit Diagram) – SONY KF-50SX100 - 50SX100K - 50SX100U LCD PROJECTION TV

↧

HOW TO ENTER SERVICE MODE - SONY KF-50SX100/50SX100K/50SX100U

SONY KF-50SX100 - SONY KF50SX100K - SONY KF50SX100U - SERVICE MODE & DEFAULT DATA VALUES.

To enter service mode; you have to first enter its "TT' mode; and then enter the "Service mode". The proceedings are:To Enter TT Mode

1) Turn on the main power switch to place this set in standby mode. (LED will light in red.)

2) Press the buttons on commander as follows, and the TT mode will be selected.

[+ 1 (On screen Display)] > [5 (Digit-5)] > [Vol --] > [TV Mode] > Enter the TT mode. {“TT - -” will appear in the top right corner of the screen. Other status information will also be displayed.}

3) Press “0” + “0” on the commander. If “ (TV MODE)” button is pressed, the set exits from the TT mode and returns to normal TV mode.

How to Enter Service Menu

1] Select TT mode.

2] Press “MENU” button on the commander once, and normal menu screen will appear, or press it once more, and the following service menu screen will appear.

Service AE5(A)

Initialising

Reset Devices

Monitoring

Device Register Setting

Special Adjustment

Select : ▲/▼ Next menu : ►

3] Following the screen, press ▲/▼ on the joystick to select the desired item, and press ► key to enter the selected item.

4] Press▲/▼ key on the joystick to change data of each item, and press “ (OK)” button to write changed data. (Except Projector Engine mode)

5] To return from each item, press◄ key on the joystick. Or, to return to the TT mode, press the “MENU” button. (Except Projector Engine mode)

Screen Display for Service Menu

If each item of service menu is selected, the following screen is displayed.

Initialising

Model Setting

Destination Setting

Basic Setting

Feature Setting

Select : ▲/▼ Next menu : ►

CLICK ON THE TABLES TO MAGNIFY

↧