Gaggenau_Siemens_Theremador & Bosch dishwashers_ how to replace Heater & NTC _ Error codes.

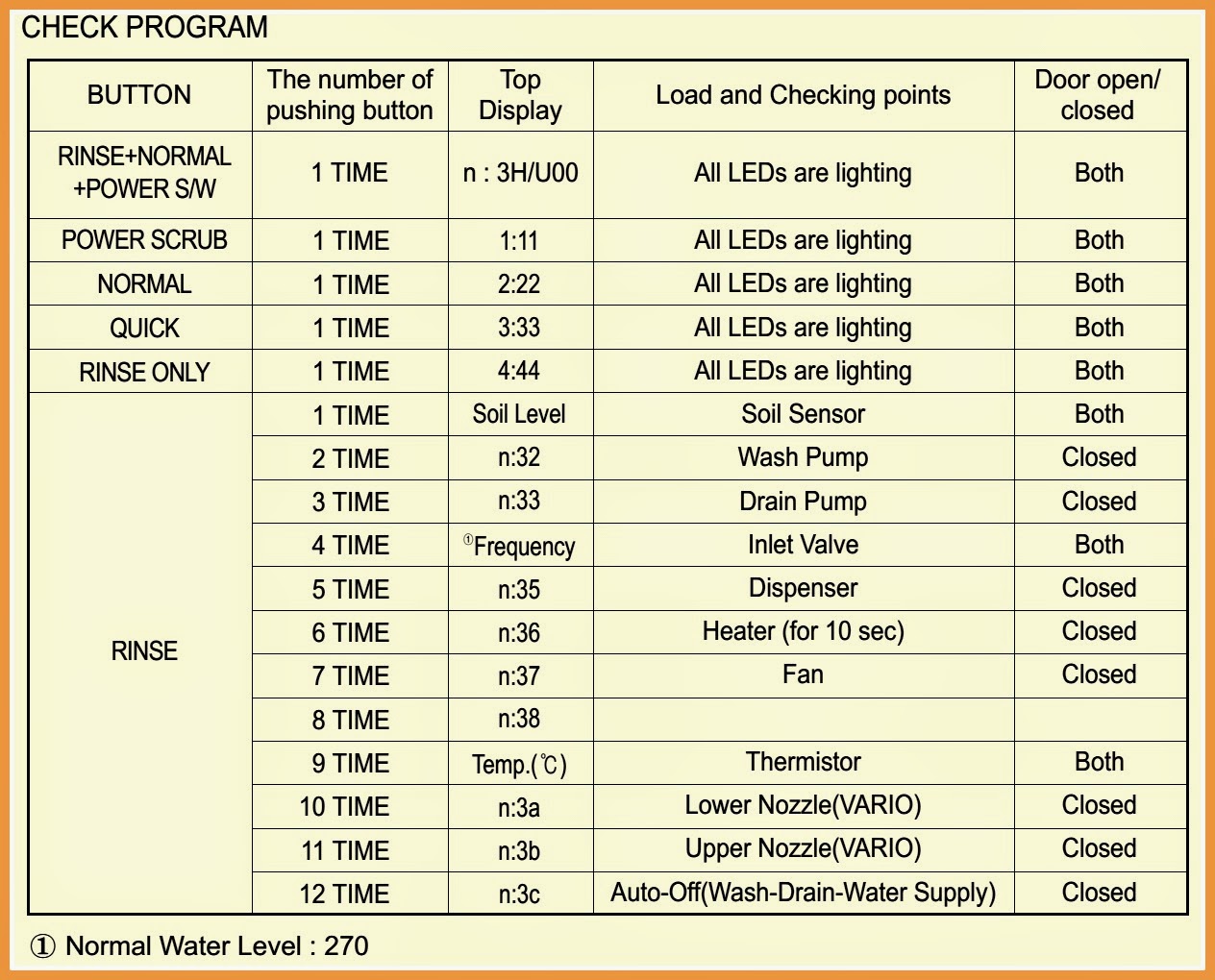

ERROR CODES

P(X) Program codes

P0 = Functional test - used for assembly

P1 = Customer service test program

P3 = Endurance/Life test

P4 = Control coding (see “C(X)” control codes below)

E(X) Error codes

E0 = No errors

E1 = Heating error

E2 = NTC error

E3 = Filling error

E4 = Water switch cannot be positioned

E5 = Safety level reached E6 = Aqua sensor error

C(X) Control Codes

Codes C1 to C9 possible, depending on DW model.

{Pushing Cancel-Drainer Cancel-Reset buttons while dw’s are off can see codes, leading to service calls.}

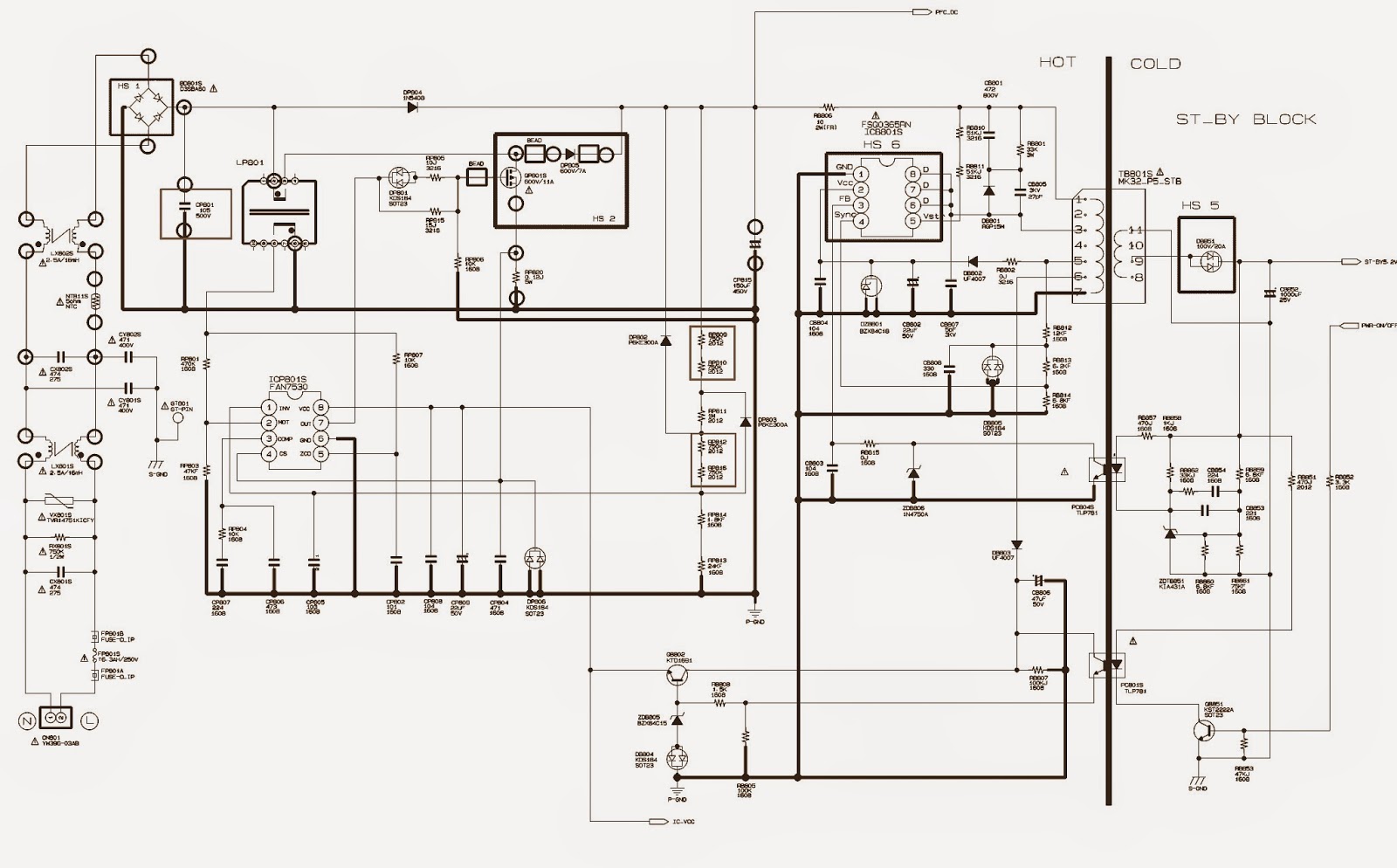

ERROR CODE-1

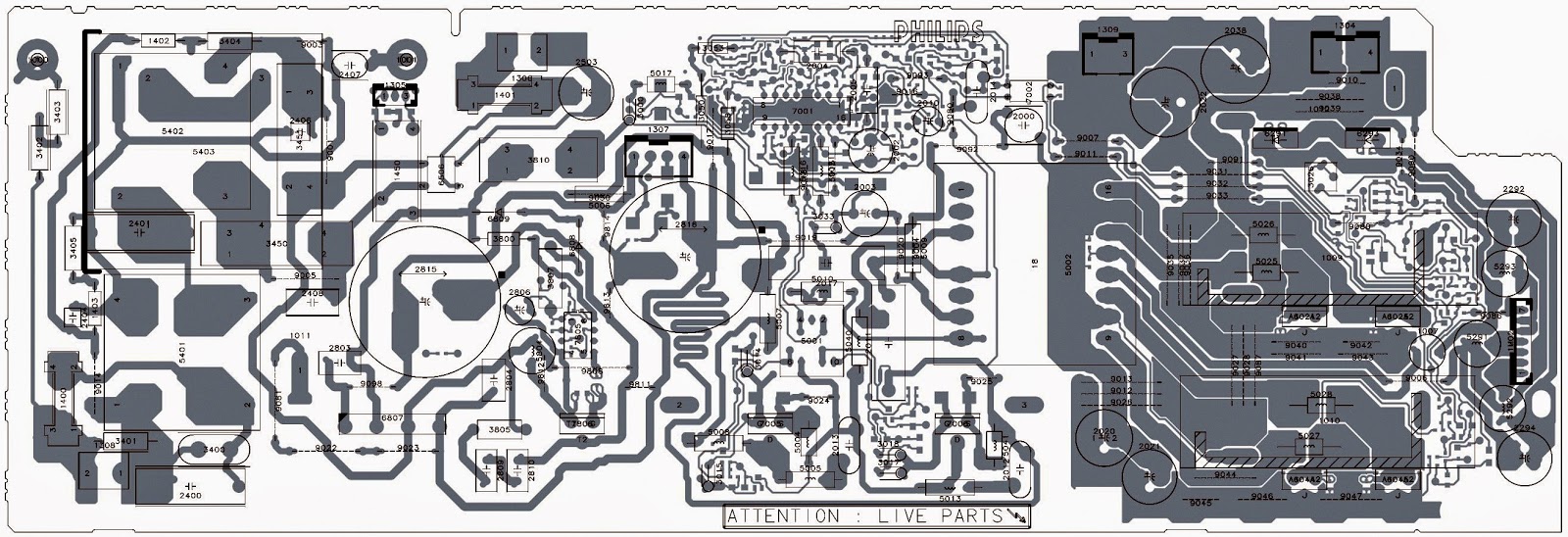

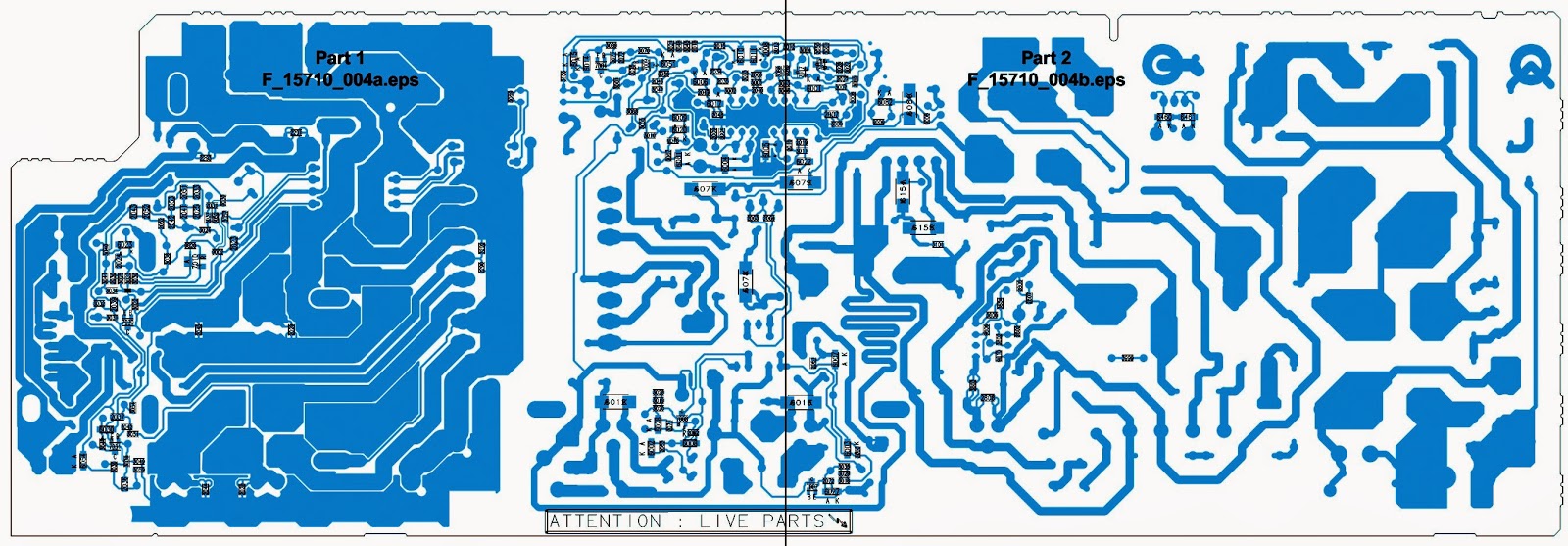

Occasionally dishwashers can run for hours, not finish washing & show a “1” in the display. This means the module has timed out due to an unidentified heating problem --all heating related parts must be checked until the problem is found.

[Modules have been replaced when problem was loose connections. Before replacing modules, check connections first. Whenever a “1” shows in the module display, the module must be reset (after the heating problem has been fixed) by running the dishwasher. The module resets after the 1st run. Check module heater relays, wire harnesses / terminals & heaters before checking NTC’s, flow switches & high limits.]

HEATER OPERATION

Flow through heater heats water without an exposed tank element. Filtered water enters the heater from the circulation pump. The heater heats water when the flow switch signals water is present.

The sump also contains an aqua sensor, drain pump, NTC, Hi-limit and back-flow valve. The aqua sensor senses water cleanliness – dishwashers add rinses if needed. The NTC senses water temperature. The Hi-limit shuts off the heater if the water gets too hot. The back-flow valve prevents waste water from entering the dishwasher.

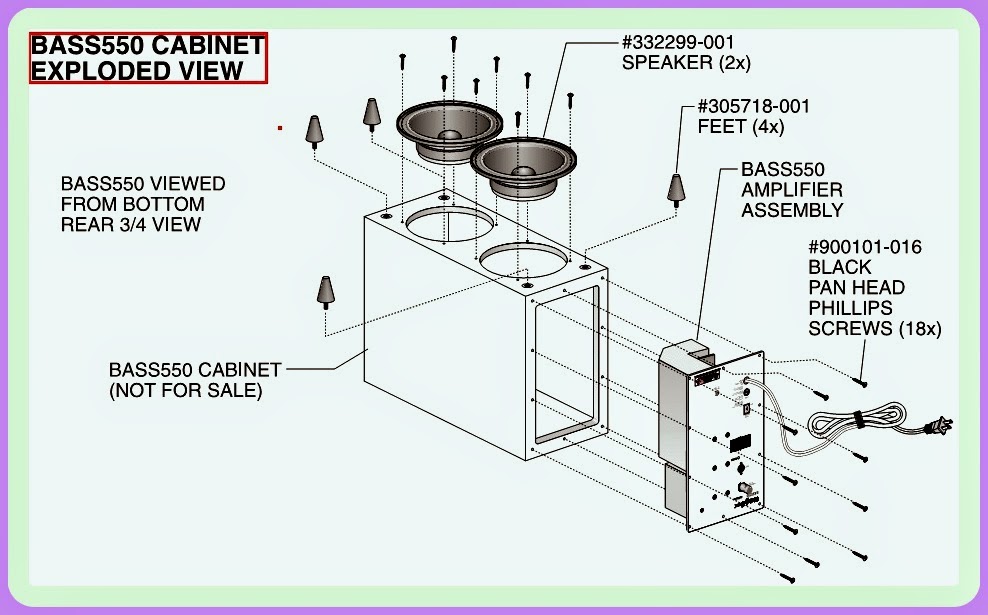

HEATER & NTC DIS-ASSEMBLY

· The heater & NTC can be accessed or measured from the right side of the dishwasher, but can only be removed by dropping the entire base (by flipping the dishwasher on its back) since they are wedged underneath the tank.

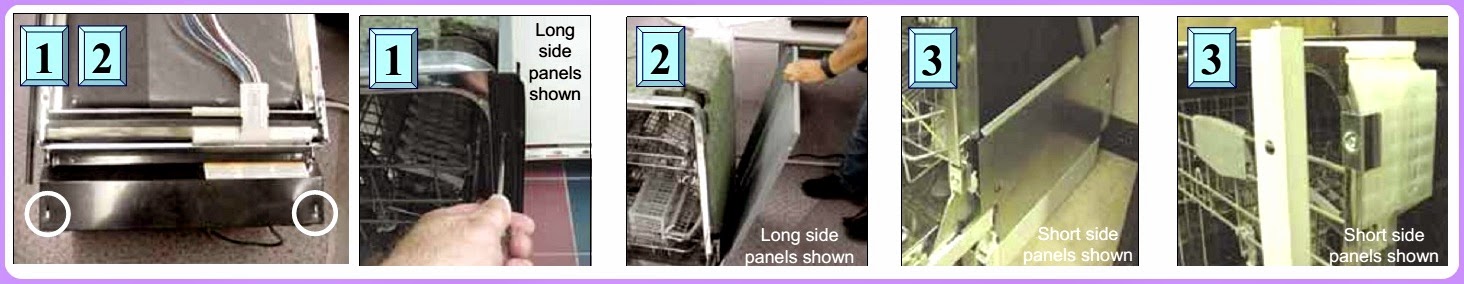

> Remove outer door. {See the previous post here; to get details about door removal}

> Remove toe kick

> Remove right/left side panels.

> Raise right side of tank.

[The fascia panel and door don’t need to be removed to access the heater & NTC. However, the door must be removed to completely remove the tank. Remove all water from the sump and hoses before accessing the heater -- when the dishwasher is flipped on its back, water can enter the water fill assembly diaphragm and cause the dishwasher to not fill properly.]

TO SEPARATE THE BASE FROM THE TANK

* Lay dishwasher on its back.

* Pull door springs out from base.

* Remove terminal blocks from base (for two-piece harnesses).

* Disconnect hose from water valve (or remove water valve from base if easier).

* Disconnect J-box ground wire, then pull wires out of J-box.

* Pull out inlet hose from sump.

* Carefully pull base away from tank and sump.

{Remove water from sump and hoses before laying dishwasher on its back (to avoid water entering water fill assembly & causing faulty water filling)}

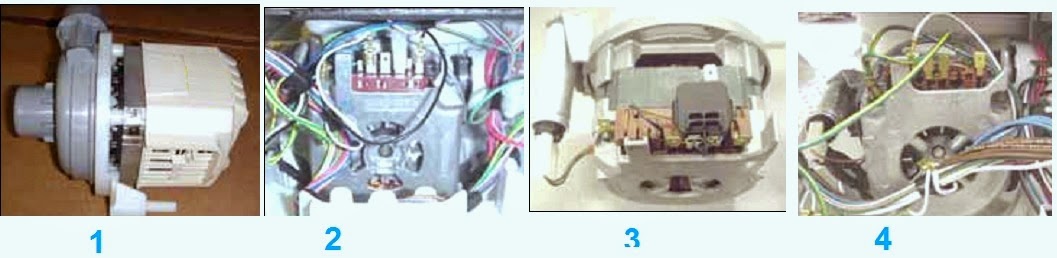

TO REMOVE HEATER AND NTC

The heater & NTC can be accessed or measured from the right side of the dishwasher, but can only be removed by dropping the entire base (by flipping the dishwasher on its back) since they are wedged underneath the tank.

> Remove two (2) T-20 Torx screws holding heater assembly to sump.

> Disconnect wires from heater, flow switch, NTC & Hi-Limit after noting connections.

> Pull clips, then carefully pull heater assembly from sump & pump. Note: heater comes as an assembly (with housing & gasket).

[Softer bearing & no softer bearing heater assemblies, circulation pumps and sumps cannot be mixed and matched. Softer bearing heaters don’t fit in older models and older heaters don’t fit in softer bearing models. If needed, use rinse aid to lubricate gaskets to make it easier to assemble heater to sump and pump.]

Softer bearing & non-softer bearing heater assemblies are connected to circulation pumps differently. Softer bearing models(UC/11 & above) have gasket assembled to heater and have a separate hose clamp (order #172272). Older models(UC/06) have a separate gasket and do not have a hose clamp. Heater assemblies contain NTC’s, Hi-Limit’s & flow switches(&aqua sensors where applicable). If heaters are replaced, these parts are replaced too.

CLICK ON THE PICTURES TO MAGNIFY