Error Codes – LED blinking codes _ fault finding - PHILIPS 26PFL5332D-32PFL5332D-37PFL5332D-42PFL5332D

ERROR CODES

The error code buffer contains all detected errors since the last time the buffer was erased. The buffer is written from left to right, new errors are logged at the left side, and all other errors shift one position to the right. When an error has occurred, the error is added to the list of errors, provided the list is not full or the error is a protection error. When an error occurs and the error buffer is full, then the new error is not added, and the error buffer stays intact (history is maintained), except when the error is a protection error. To prevent that an occasional error stays in the list forever, the error is removed from the list after 50+ operation hours. When multiple errors occur (errors occurred within a short time span), there is a high probability that there is some relation between them.

> Errors detected by the Stand-by Processor. These errors will always lead to protection and an automatic start of the blinking LED for the concerned error (The Blinking LED Procedure). In these cases SDM can be used to start up.

> Errors detected by VIPER that lead to protection. In this case the TV will go to protection and the front LED will blink at 3 Hz. Further diagnosis via service modes is not possible

here.

> Errors detected by VIPER that do not lead to protection. In this case the error can be read out via ComPair, via the blinking LED method, or in case you have picture, via SAM.

HOW TO READ THE ERROR BUFFER

Use one of the following methods

* On screen via the SAM (only if you have a picture). E.g.:

> 00 00 00 00 00: No errors detected

> 06 00 00 00 00: Error code 6 is the last and only detected error

> 09 06 00 00 00: Error code 6 was first detected and error code 9 is the last detected error

* Via the blinking LED procedure (when you have no picture).

* Via com-pair.

HOW TO CLEAR THE ERROR BUFFER

Use one of the following methods

* By activation of the “RESET ERROR BUFFER” command in the SAM menu.

* With a normal RC, key in sequence “MUTE” followed by “062599” and “OK”.

* If the content of the error buffer has not changed for 50+ hours, it resets automatically.

ERROR BUFFER

In case of non-intermittent faults, clear the error buffer before you begin the repair (before clearing the buffer, write down the content, as this history can give you significant information). This to ensure that old error codes are no longer present. If possible, check the entire contents of the error buffer. In some situations, an error code is only the result of another error code and not the actual cause (e.g., a fault in the protection detection circuitry can also lead to a protection).

There are several mechanisms of error detection

* Via error bits in the status registers of ICs.

* Via polling on I/O pins going to the stand-by processor.

* Via sensing of analogue values on the stand-by processor.

* Via a “not acknowledge” of an I2 C communication

Take notice that some errors need more than 90 seconds before they start blinking. So in case of problems wait 2 minutes from start-up onwards, and then check if the front LED is blinking.

ERROR CODES

Error 1 (I2 C bus 1 blocked).

When this error occurs, the TV will go to protection and the front LED will blink at 3 Hz. Now you can partially restart the TV via the SDM shortcut pins on the SSB. Depending on the software version it is possible that no further diagnose (error code read-out) is possible. With the knowledge that only errors 1, 2, 4, and 63 result in a 3 Hz blinking LED, the range of possible defects is limited.

Error 2 (I2 C bus 2 blocked).

When this error occurs, the TV will go to protection and the front LED will blink at 3 Hz. Now you can partially restart the TV via the SDM shortcut pins on the SSB. Due to hardware restriction (I2 C bus 2 is the fast I2 C bus) it will be impossible to start up the VIPER and therefore it is also impossible to read out the error codes via ComPair or via the blinking LED method. With the knowledge that only errors 1, 2, 4, and 63 result in a 3 Hz blinking LED, the range of possible defects is limited. When you have restarted the TV via the SDM shortcut pins, and then pressed "CH+" on your remote control, the TV will go to protection again, and the front LED blink at 3 Hz again. This could be an indication that the problem is related to error 2.

Error 3 (I2 C bus 3 blocked).

There are only three devices on I2 C bus 3: VIPER, Stand-by Processor, and NVM. The Stand-by Processor is the detection device of this error, so this error will only occur if the VIPER or the NVM is blocking the bus. This error will also be logged when the NVM gives no acknowledge on the I2 C bus (see error 44). Note that if the 12 V supply is missing (connector 1M46 on the SSB), the DC/DC supply on the SSB will not work. Therefore the VIPER will not get supplies and could block I2 C bus 3. So, a missing 12 V can also lead to an error 3.

Error 4 (I2 C bus 4 blocked).

Error 4 is displayed in SAM. No protection.

Error 5 (Viper doesn’t boot).

This error will point to a severe hardware problem around the VIPER (supplies not OK, VIPER completely dead, I2 C link between VIPER and Stand-by Processor broken, etc. ...).

Error 7 (8.6 V error).

Except a physical problem with the 8.6 V itself, it is also possible that there is something wrong with the Audio DC Protection: see paragraph "Hardware Protections" for this.

Error 12 (12 V error).

Except a physical problem with the 12 V itself, it is also possible that there is something wrong with the Audio DC Protection: see paragraph "Hardware Protections" for this.

• Error 14 (Audio supply). This error is triggered in case of too low voltage of the audio supplies and therefore a drop of the audio supply voltage of below approx. 9 V per supply rail (or lower than 18 V rail to rail). Also a DC voltage of higher than 1 V DC on the speakers will lead to protection and error 14 blinking. For LCD sets this circuit can be found on schematic SA3, for PDP sets this can be found on schematic C. It should be noted that for 26-inch models there is only a supply link between the amplifiers and the stand-by μC whereas in all other models this link is implemented by Audio-Prot line pin 7 on 1 M02.

Error 18 (MPIF1).

Error 18 is displayed in SAM. No protection.

Error 21 (HDMI switch).

Error 21 is displayed in SAM. No protection.

Error 25 (Supply fault).

When this error occurs, the TV will go to protection and the front LED will blink at 3 Hz.

Error 29 (AVIP1).

This error will probably generate extra errors. You will probably also see errors 32 (MPIF) and error 31 (AVIP 2). Error 29 and 31 will always be logged together due to the fact that both AVIPs are inside the PNX2015 and are on the same I2 C bus. In this case start looking for the cause around AVIP (part of PNX2015).

Error 31 (AVIP2). See info on error 29.

Error 34 (Tuner 1).

When this error is logged, it is not sure that there is something wrong with the tuner itself. It is also possible that there is something wrong with the communication between channel decoder and tuner.

Error 37 (Channel decoder).

This error will always log error 34 (tuner) extra. This is due to the fact that the tuner I2C bus is coming from the channel decoder.

Error 44 (NVM).

This error will never occur because it is masked by error 3 (I2 C bus 3). The detection mechanism for error 3 checks on an I2 C acknowledge of the NVM. If NVM gives no acknowledge, the stand-by software assumes that the bus is blocked, the TV goes to protection and error 3 will be blinking.

Error 53.

This error will indicate that the VIPER has started to function (by reading his boot script, if this would have failed, error 5 would blink) but initialization was never completed because of hardware peripheral problems (NAND flash, ..) or software initialization problems. Possible cause could be that there is no valid software loaded (try to upgrade to the latest main software version).

BLINKING LED PROCEDURE

How to Activate

Use one of the following methods:

* Activate the SDM. The blinking front LED will show the entire contents of the error buffer (this works in “normal operation” mode).

* Transmit the commands “MUTE” - “062500” - “OK” with a normal RC. The complete error buffer is shown. Take notice that it takes some seconds before the blinking LED starts.

* Transmit the commands “MUTE” - “06250x” - “OK” with a normal RC (where “x” is a number between 1 and 5). When x= 1 the last detected error is shown, x= 2 the second last error, etc.... Take notice that it takes some seconds before the LED starts blinking.

The blinking LED procedure can be split up into two situations

* Blinking LED procedure in case of a protection detected by the stand-by processor. In this case the error is automatically blinked. This will be only one error, namely the one that is causing the protection. Therefore, you do not have to do anything special, just read out the blinks. A long blink indicates the decimal digit; a short blink indicates the units.

* Blinking LED procedure in the “ON” state. Via this procedure, you can make the contents of the error buffer visible via the front LED. This is especially useful for fault finding, when there is no picture.

When the blinking LED procedure is activated in the “ON” state, the front LED will show (blink) the contents of the error-buffer. Error-codes > 10 are shown as follows

1.“n” long blinks (where “n” =1 - 9) indicating decimal digit,

2. A pause of 1.5 s,

3.“n” short blinks (where “n”= 1 - 9),

4. A pause of approx. 3 s.

5. When all the error-codes are displayed, the sequence finishes with a LED blink of 3 s,

6. The sequence starts again.

Example:Error 12 9 6 0 0.

After activation of the SDM, the front LED will show:

1. 1 long blink of 750 ms (which is an indication of the decimal digit) followed by a pause of 1.5 s,

2. 2 short blinks of 250 ms followed by a pause of 3 s,

3. 9 short blinks followed by a pause of 3 s,

4. 6 short blinks followed by a pause of 3 s,

5. 1 long blink of 3 s to finish the sequence,

6. The sequence starts again.

PROTECTIONS

Software Protections

Most of the protections and errors use either the stand-by microprocessor or the VIPER controller as detection device. Since in these cases, checking of observers, polling of ADCs,

filtering of input values are all heavily software based, these protections are referred to as software protections. There are several types of software related protections, solving

a variety of fault conditions:

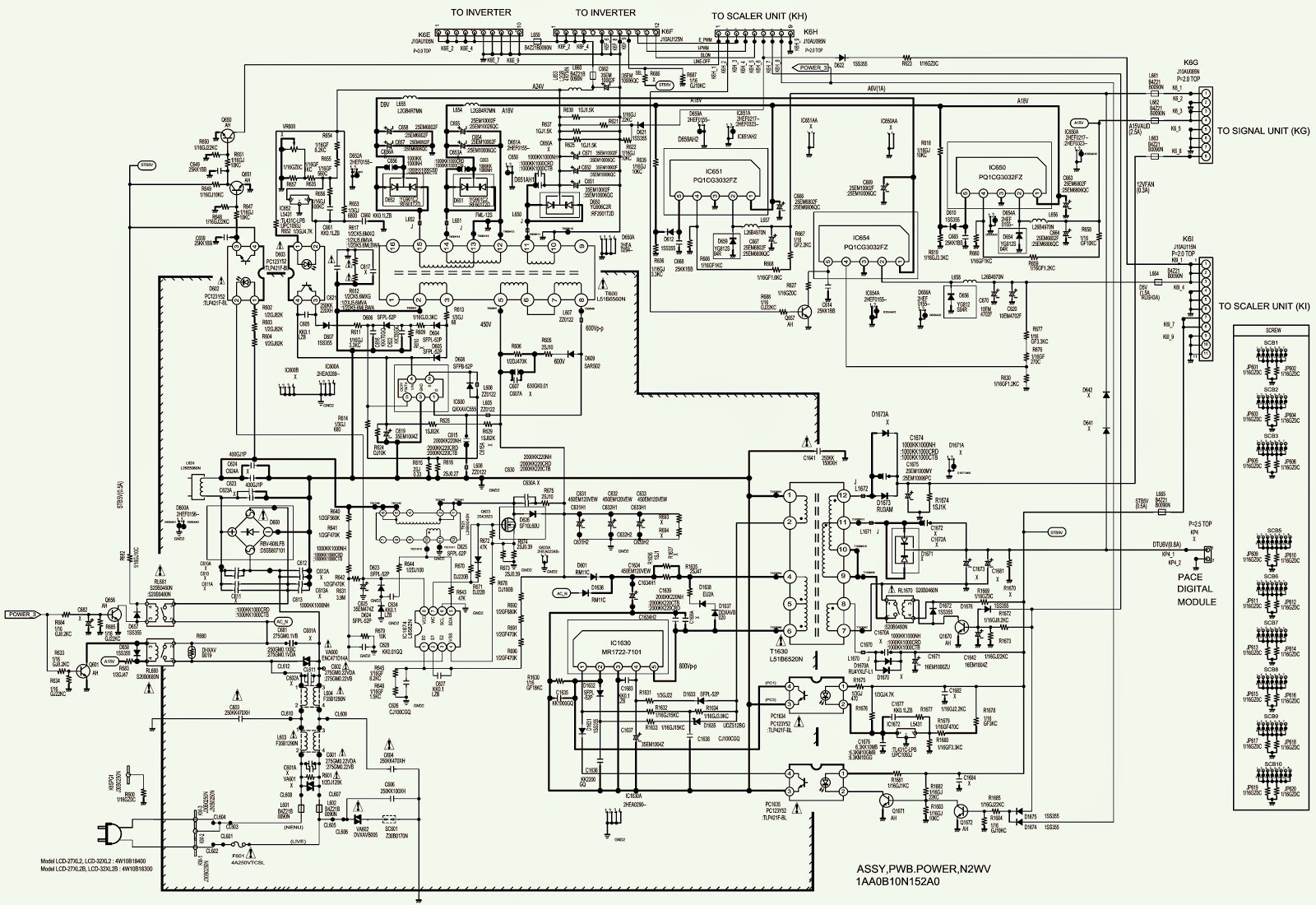

> Protections related to supplies: check of the 12V, +5V,+8V6, +1.2V, +2.5V and +3.3V.

> Protections related to breakdown of the safety check mechanism. E.g. since a lot of protection detection are done by means of the VIPER, failing of the VIPER communication will have to initiate a protection mode since safety cannot be guaranteed anymore.

The detection of a supply dip or supply loss during the normal playing of the set does not lead to a protection, but to a cold reboot of the set.

Protections during Start-up

During TV start-up, some voltages and IC observers are actively monitored to be able to optimize the start-up speed, and to assure good operation of all components. If these monitors do not respond in a defined way, this indicates a malfunction of the system and leads to a protection.

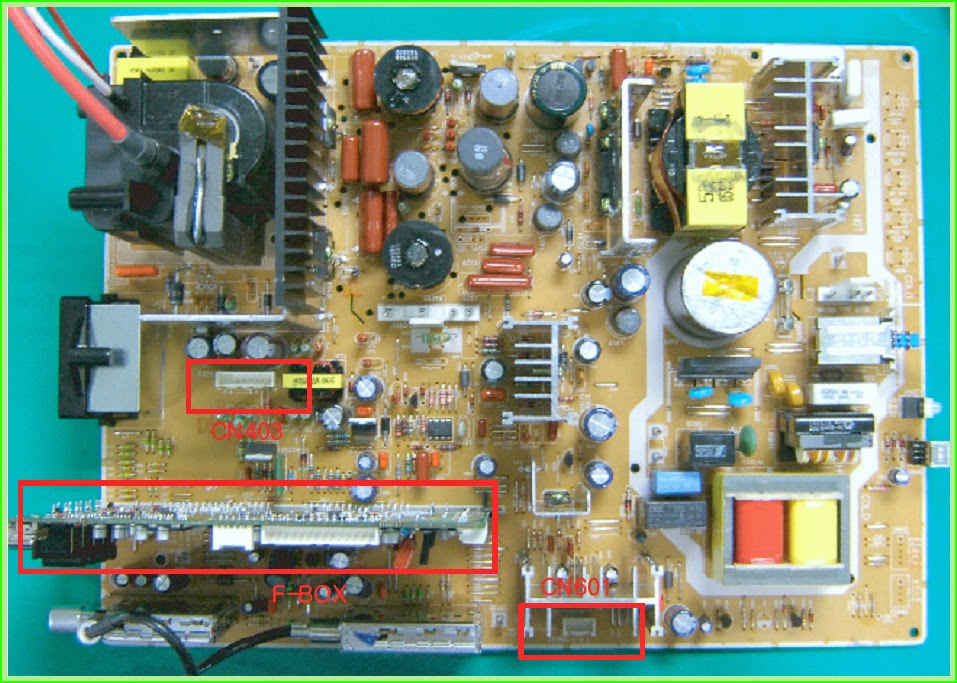

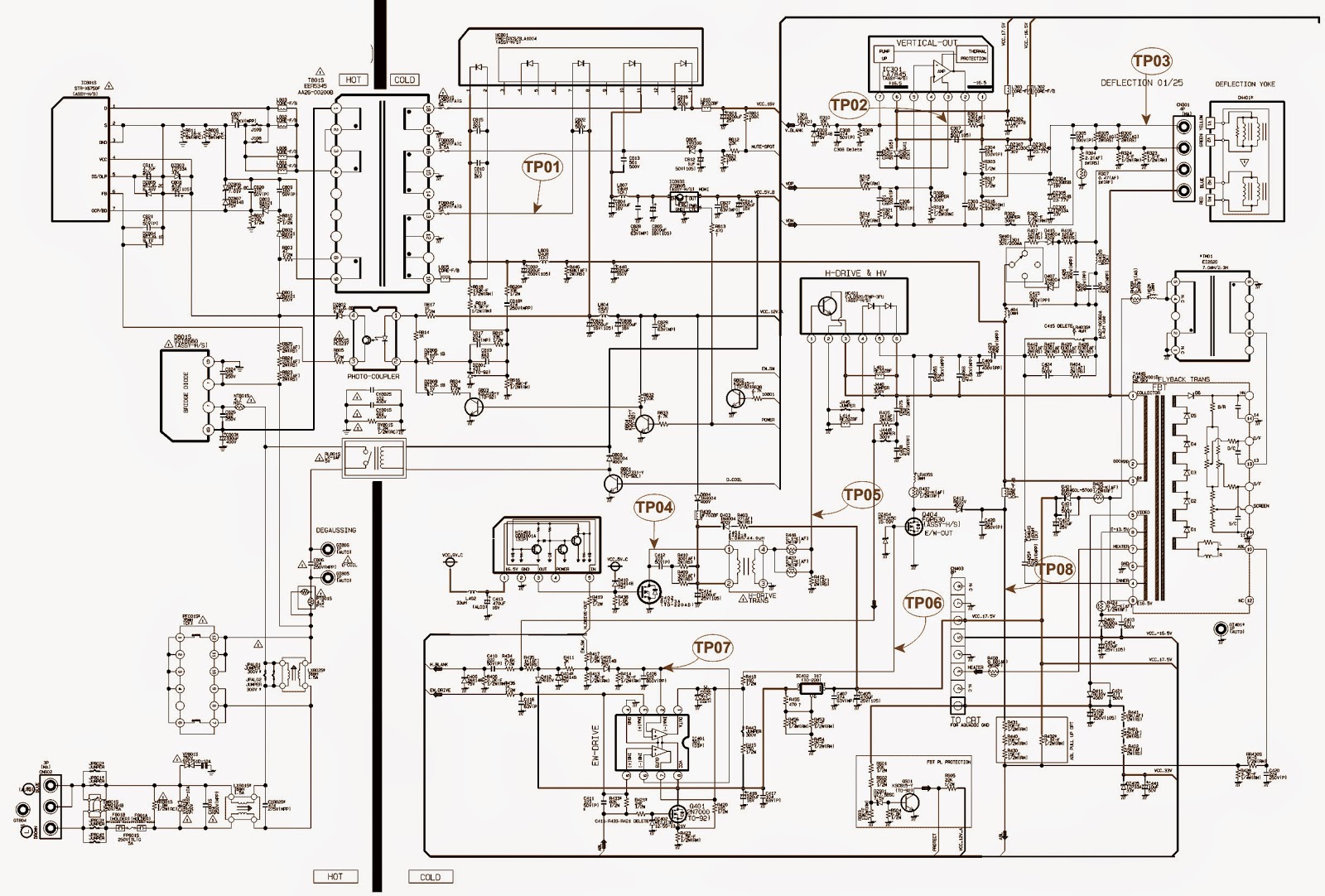

HARDWARE PROTECTIONS

There is one hardware protection in this chassis: “Audio DC Protection”. This protection occurs when there is a DC voltage on the speakers. In that case the main supply is switched

"OFF", but the stand-by supply is still working. In case of LCD supplies, the 12V supply will drop. This will be detected by the stand-by processor, which will start blinking the 12 V error (error 12).

Repair Tip

* It is also possible that you have an audio DC protection because of an interruption in one or both speakers (the DC voltage that is still on the circuit cannot disappear through the speakers).

FAULT FINDING TIPS

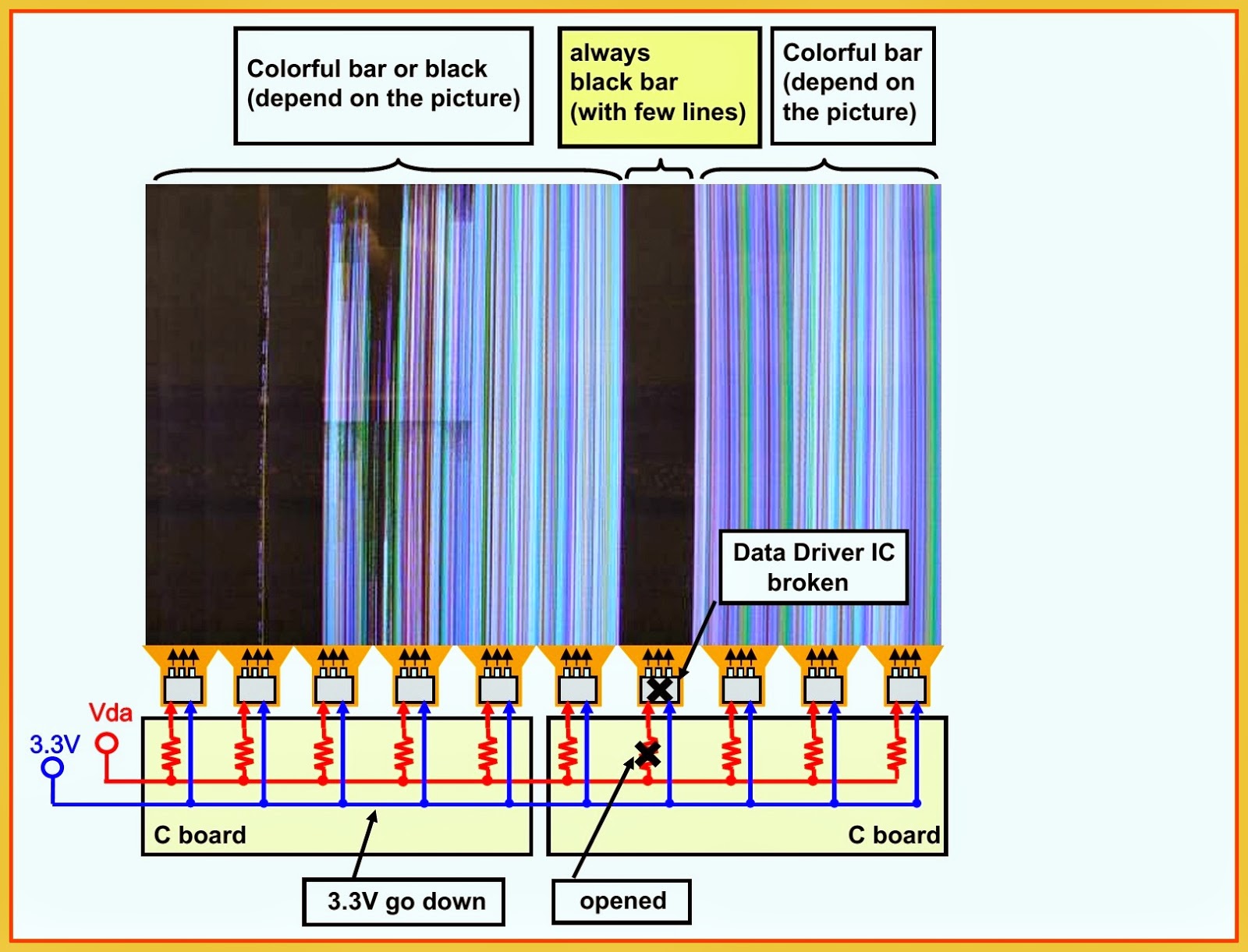

> Symptom: +1V2, +2V5, and +3V3 not present (even for a short while ~10ms).

1. Check 12V availability (fuse 1U01, resistor 3U22, power MOSFETs) and enable signal ENABLE-1V2 (active low).

2. Check the voltage on pin 9 (1.5 V).

3. Check for +1V2 output voltage short-circuit to GND that can generate pulsed over-currents 7-10 A through coil 5U03.

4. Check the over-current detection circuit (2U12 or 3U97 interrupted).

> Symptom: +1V2 present for about 100 ms. Supplies +2V5 and +3V3 not rising.

1. Check the ENABLE-3V3 signal (active "low").

2. Check the voltage on pin 8 (1.5 V).

3. Check the under-voltage detection circuit (the voltage on collector of transistor7U10-1 should be less than 0.8 V).

4. Check for output voltages short-circuits to GND (+3V3, +2V5 and +2V5D) that generate pulsed over-currents of 7-10 A through coil 5U00.

5. Check the over-current detection circuit (2U18 or 3U83 interrupted).

> Symptom: +1V2 OK, but +2V5 and +3V3 present for about 100 ms.

Cause: The SUPPLY-FAULT line stays "low" even though the +3V3 and +1V2 is available. The Stand-by

Processor is detecting that and switches all supply voltages "OFF".

1. Check the drop voltage across resistor 3U22 (this could be too high)

2. Check if the +1V2 or +3V3 are higher than their normal values. This can be due to defective DC feedback of the respective DC/DC converter (3U18 or 3UA7).

> Symptom: +1V2, +2V5, and +3V3 look okay, except the ripple voltage is increased (audible noise can come from the filtering coils 5U00 or 5U03).

Cause: Instability of the frequency and/or duty cycle of one or both DC/DC converters.

– Check resistor 3U06, the decoupling capacitors, the AC feedback circuits (2U20 + 2U21 + 3U14 + 3U15 for +1V2 or 2U19 + 2U85 + 3U12 + 3U13 for +3V3), the compensation capacitors 2U09, 2U10, 2U23 and 2U73, and IC 7U00. {If fuse 1U01 is broken, this usually means a pair of defective power MOSFETs (7U01 or 7U03). Item 7U00 should be replaced as well in this case.