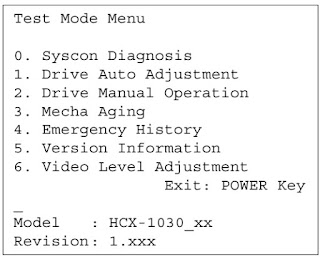

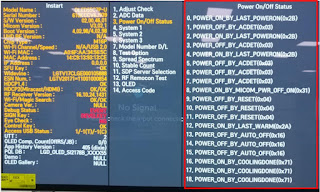

The CSM is a Service Mode that can be enabled by the consumer. The CSM displays diagnosis information, which the customer can forward to the dealer or call centre. In CSM mode, “CSM”, is displayed in the top right corner of the screen.

The information provided in CSM and the purpose of CSM is to:

• Increase the home repair hit rate.

• Decrease the number of nuisance calls.

• Solved customers’ problem without home visit.

Note: For the new model range, a new remote control (RC) is used with some renamed buttons. This has an impact on the activation of the Service modes. For instance the old “MENU” button is now called “HOME” (or is indicated by a “house” icon).

Software Identification, Version, and Cluster

The software ID and version will be shown in the main menu display of CSM.

The screen will show: “AAAAB-X.YYY”, where:

• AAAA is the chassis name: TPS152A x.yyy.

• B is the region indication: E = Europe, A = AP/China, U = NAFTA, L = LATAM.

• X is the main version number: this is updated with a major change of specification (incompatible with the previous software version). Numbering will go from 1 - 99 and AA - ZZ.

- If the main version number changes, the new version number is written in the NVM.

- If the main version number changes, the default settings are loaded.

• YYY is the sub version number: this is updated with a minor change (backwards compatible with the previous versions). Numbering will go from 000 - 999.

- If the sub version number changes, the new version number is written in the NVM.

- If the NVM is refreshed, the software identification, version, and cluster will also be written to NVM.

Customer Service Mode (CSM): Purpose

The Customer Service Mode shows error codes and information on the TV’s operation settings. The call centre can instruct the customer (by telephone) to enter CSM in order to identify the status of the set. This helps the call centre to diagnose problems and failures in the TV set before making a service call.

The CSM is a read-only mode; therefore, modifications are not possible in this mode.

• Ignore “Service unfriendly modes”. • After leaving the Customer Service Mode, the original settings are restored.

• Possibility to use “CH+” or “CH-” for channel surfing, or enter the specific channel number on the RC.

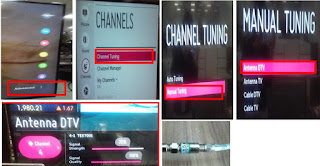

How to Activate CSM

To activate CSM, press the following key sequence on a standard remote control transmitter: from the “Menu/Home screen” press “456987”, directly followed by the “Back” button. (do not allow the display to time out between entries while keying the sequence).

After entering the Customer Service Mode, the following items are displayed.

Note: Activation of the CSM is only possible if there is no (user) menu on the screen

Contents of CSM

Set Type This information is very helpful for a helpdesk/workshop as reference for further diagnosis. In this way, it is not necessary for the customer to look at the rear of the TV-set. Note that if an NVM is replaced or is initialized after corruption, this set type has to be re-written to NVM.

Production code Displays the production code (the serial number) of the TV. Note that if an NVM is replaced or is initialized after corruption, this production code has to be re-written to NVM.

Key (HDCP) Indicates the validity of the HDMI keys (or HDCP keys). In case these keys are not valid and the customer wants to make use of the HDMI functionality, the SSB has to be replaced.

NVM name Detects and displays NVM name.

Software Version Displays the software version.

SW cluster name Displays the software cluster name.

RS232 Display RS232.

TV Region Display TV region.

How to Exit CSM

To exit CSM, use one of the following methods.

• Press the MENU/HOME button on the remote control transmitter.

• Press the POWER button on the remote control transmitter.

• Press the POWER button on the television set.

How to Activate the Factory mode

To activate the Factory mode, use the following method:

• Press the following key sequence on the remote control transmitter: from the “Menu/Home screen” press “1999”, directly followed by the “Back” button. Do not allow the display to time out between entries while keying the sequence.

How to Exit the Factory mode

Use one of the following methods:

• Select EXIT_FACTORY from the menu and press the “OK” button.

Note: When the TV is switched “off” by a power interrupt, or normal switch to “stand-by” while in the factory mode, the TV will show up in “normal operation mode” as soon as the power is supplied again. The error buffer will not be cleared.

General Alignment Conditions

Perform all electrical adjustments under the following conditions:

• Power supply voltage: 90 - 264 VAC, 50/ 60 3 Hz.

• Connect the set to the mains via an isolation transformer with low internal resistance.

• Allow the set to warm up for approximately 15 minutes.

• Measure voltages and waveforms in relation to correct ground (e.g. measure audio signals in relation to AUDIO_GND).

Caution: It is not allowed to use heat sinks as ground.

• Test probe: Ri > 10 M, Ci < 20 pF.

• Use an isolated trimmer/screwdriver to perform alignments.

Reset of Repaired SSB

A very important issue towards a repaired SSB from a Service repair shop (SSB repair on component level) implies the reset of the NVM on the SSB.

After a repaired SSB has been mounted in the set (set repair on board level), the type number (CTN) and production code of the TV has to be set according to the type plate of the set.

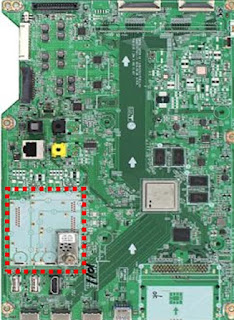

SSB Identification

SSB’s of this chassis are identified by a “715” code on the SSB.

715Axxxx-Nnn-MMM-OOOO

• 715 main category, Printed Wiring Board

• Axxxx sub category, sequential coding number

• Nnn Version code

• N Development number

• nn Production number

• MMM Mounting variation code

• OOOO Optional variation code

Make sure when replacing an SSB the SSB identification codes match the replacement board.

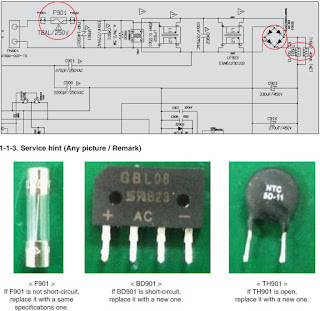

Power Supply Unit

All power supplies are a black box for Service. When defective, a new board must be ordered and defective one must be returned, unless the main fuse of the board is broken. Always replace a defective fuse with one with the correct specifications. This part is available in the regular market.

Consult the Philips Service web portal for the order codes of the boards.

Important delta’s with the TPS15.2A LA classis platform are:

• New power architecture for LED backlight

• “Boost” signal is now a PWM-signal + continuous variable.

The control signals are:

• Stand-by

• Lamp “on/off”

• DIM (PWM) (not for PSDL)

no detailed information is available because of design protection issues.

The output voltages to the chassis are:

• +12V(on-mode), +8.5V(Stand-by mode)

• +12V_Audio (on-mode),+8.5V_Audio(Stand-by mode )

• +22V for 40", +36V/+24V for 50"/ 55" (bolt-on power) (on-mode)

• Output to the display; in case of

- IPB: High voltage to the LCD panel

- PSL and PSLS (LED-driver outputs)

- PSDL (high frequent) AC-current.

Diversity

The diversity in power supply units is mainly determined by the diversity in displays.

The following displays can be distinguished:

• CCFL/EEFL backlight: power board is conventional IPB

• LED backlight:

- side-view LED without scanning: PSL power board

- side-view LED with scanning: PSLS power board

- direct-view LED without 2D-dimming: PSL power board

- direct-view LED with 2D-dimming: PSDL power board.

PSL stands for Power Supply with integrated LED-drivers.

PSLS stands for a Power Supply with integrated LED-drivers with added Scanning functionality (added microcontroller).

PSDL stands for a Power Supply for Direct-view LED backlight with 2D-dimming.

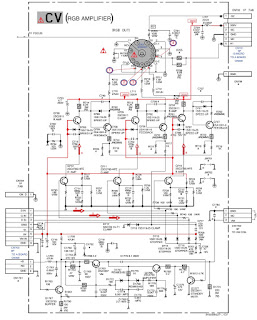

DC/DC Converters

The on-board DC/DC converters deliver the following voltages (depending on set execution):

• +5V-STANDBY, permanent voltage for the Stand-by controller

• +3V3-STANDBY, power supply for LED/IR receiver and controls

• +12V, input from the power supply for the panel common (active mode)

• +12V, input from the power supply for the amplifier

• +1V5, supply voltage for DDR

• +3V3, general supply voltage

• +3.3V-TUN, supply voltage for tuner

• +3.3V, supply voltage for Headphone AMP

• +5V-USB, input intermediate supply voltage for USB Power

• +3V3 from the power supply for the scaler IC MST6852LP

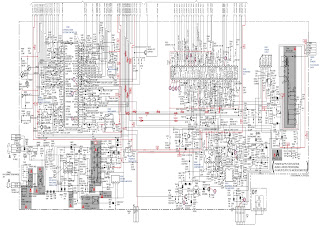

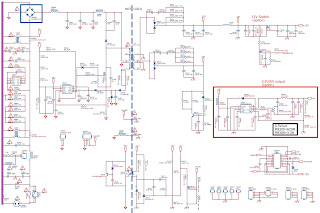

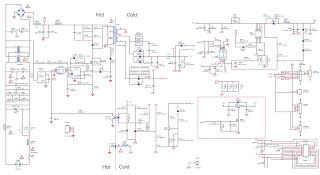

A 715G6934 PSU circuit diagram (Schematic)

Software Upgrading

Description

It is possible for the user to upgrade the main software via the USB port. This allows replacement of a software image in a stand alone set. A description on how to upgrade the main software can be found in the DFU or on the Philips website.

Introduction

Philips continuously tries to improve its products, and it’s recommend that the TV software is updated when updates are available. Software update files can be obtained from the dealer or can be downloaded from the following websites:

http://www.philips.com/support

Preparing a portable memory for software upgrade

The following requirements have to be met:

1. A personal computer connected to the internet.

2. An archive utility that supports the ZIP-format (e.g. WinZip for Windows or Stufflt for Mac OS).

3. A FAT formatted USB memory stick (preferably empty)

Note: Only FAT/DOS-formatted memory sticks are supported.

Only use software update files that can be found on the website.

Check the current TV software version

Before starting the software upgrade procedure, it is advised to check that what the current TV software:

1. Press the “Home screen” + “1999” + “Back” button on the remote control to enter the Factory mode.

2. Use the up/down cursor keys to select “SW Ver”.

If the current software version of the TV is the same as the latest update file found on by the website, it is not necessary to update the TV software.

Download the latest software

1. Open the internet website page http://www.philips.com/support.

2. Find information and software related to the TV.

3. Select the latest software update file and download it to the PC.

4. Insert the USB memory stick into one of the USB ports of the PC.

5. Decompress the downloaded ZIP file and copy it to the root directory of the USB flash drive.

Update the TV software

1. Turn the TV on and wait for it to boot completely.

2. Insert the USB memory stick that contains the software update files in one of the TV’s USB ports.

3. The TV will detect the USB memory stick automatically.

Then a window jumps out.

Note: If the USB flash drive is not detected after power up, disconnect it and re-insert it. And no change the software name.

4. Select [Confirm] and press OK to start software updates.

5. Upgrading will now begins and the status of the updating progress will be displayed.

6. When the TV software is updated. Remove your USB flash drive, and the TV will turn on automatically.

Note:

• Do not remove the USB flash drive during the software update.

• Do not turn off the power during the software update.

• If a power failure occurs during the update, do not remove the USB flash drive from the TV. The TV will continue the software update as soon as the power comes up again.

• If an error occurs during the update retry the procedure or contact the dealer.

• it is recommended not recommend downgrading to an older version.

• Once the upgrade is finished, use the PC to remove the TV software from the USB portable memory.

Content and Usage of the One-Zip Software File

Below you find a content explanation of the One-Zip file, and instructions on how and when to use it. Only files that are relevant for Service are mentioned here.

• EDID_clustername.zip: Contains the EDID content of the different EDID NVMs. See ComPair for further instructions.

FUS_clustername_version.zip: Contains the “autorun.bin” which is needed to upgrade the TV main software and the software download application.

• NVM_clustername_version.zip: Default NVM content.

Must be programmed via ComPair.

How to Copy NVM Data to/from USB

When copying data to and from a USB memory stick, the folder “repair” is used. When inserting an empty USB memory stick, and downloading data to the stick, the TV will create this folder.

When sending data from a USB memory stick to a TV, the intended data must be available in the “repair” folder.

Note that when copying EDID data to the TV, all necessary EDID files must be in this folder.

Service mode overview for your reference.

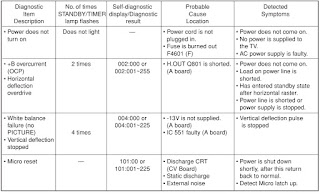

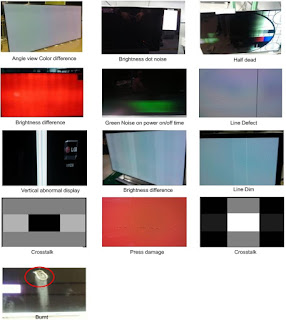

Fault Finding and Repair Tips

Note:

• It is assumed that the components are mounted correctly with correct values and no bad solder joints.

• Before any fault finding actions, check if the correct options are set.

No Picture via HDMI input

Check if HDCP key is valid. This can be done in CSM.

TV Will Not Start-up from Stand-by

Possible Stand-by Controller failure. Re-flash the software.

Audio Amplifier

The Class D-IC U601 has a power pad for cooling. When the IC is replaced it must be ensured that the power pad is very well pushed to the PWB while the solder is still liquid. This is needed to insure that the cooling is guaranteed; otherwise the Class D-IC could break down in short time.

Loudspeakers

Make sure that the volume is set to minimum during disconnecting the speakers in the ON-state of the TV. The audio amplifier can be damaged by disconnecting the speakers during ON-state of the set.

Display option code

Attention: In case the SSB is replaced, always check the Panel Code in CSM, even when picture is available. Performance with the incorrect display option code can lead to unwanted side-effects for certain conditions.