11AK19 is a 90 and 110 chassis capable of driving 20, 21,24,25,28,29,32,33 inch tubes at appropriate currents.

The chassis is capable of working in both PAL and SECAM. The sound system is capable of giving 6watts RMS output into a load of 8ohms.

One 8 page simple TELETEXT, TOPTEXT and FASTEXT is provided.

The chassis is equipped with 21-pin scart connectors which can accept via scart the SVHS format from VCRs so equipped.

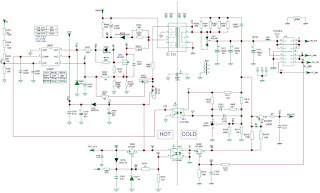

SMALL SIGNAL PART WITH TDA884X

The TDA8840/8842/8844 combine all small signal functions required for a colour TV receiver, except tuning.

Vision IF amplifier

The IF-amplifier contains 3 AC-coupled control stages with a total gain control range which is higher than 66dB.

The sensitivity of the circuit is comparable with that of modern IF-IC s. The video signal is demodulated by means of a PLL carrier regenerator. This circuit contains a frequency detector and a phase detector. The AFC output is obtained by using the VCO control voltage of the PLL and can be read via the I2C-bus. For fast search tuning systems the window of the AFC can be increased with a factor 3. The setting is realised with the AFW bit.

Depending on the type the AGC-detector operates on top-sync level (single standard versions) or on top sync and top white-level (multi standard versions). The demodulation polarity is switched via the I2C-bus. The AGC detector time-constant capacitor is connected externally. This mainly because of the flexibility of the application. The time-constant of the AGC system during positive modulation is rather long to avoid visible variations of the signal amplitude. To improve the speed of the AGC system a circuit has been included which detects whether the AGC detector is activated every frame period. When during 3 frame periods no action is detected the speed of the system is increased. For signals without peak white information the system switches automatically to a gated black level AGC. Because a black level clamp pulse is required for this way of operation the circuit will only switch to black level AGC in the internal mode.

![]()

The circuits contain a video identification circuit which is independent of the synchronisation circuit. Therefore search tuning is possible when the display section of the receiver is used as a monitor. The ident output is supplied to the tuning system via the I2C-bus. The video ident circuit can be made less sensitive by means of the STM bit. This mode can be used during search tuning to avoid that the tuning system will stop at very weak input signals.

Video Switches

The circuits have two CVBS inputs (internal and external CVBS) and Y/C input. When the Y/C input is not required the Y input can be used as third CVBS input. The selection of the various sources is made via the I†C-bus. The circuit has one CVBS output.

Sound Circuit

The sound band pass and trap filters have to be connected externally. The filtered intercarrier signal is fed to a limiter circuit and is demodulated by means of a PLL demodulator. This PLL circuit tunes itself automatically to the incoming carrier signal so that no adjustment is required.

The volume is controlled via the I2C-bus. The de-emphasis capacitor has to be connected externally. The non-controlled audio signal can be obtained from this pin. The FM demodulator can be muted via the I2C-bus. This function can be used to switch-off the sound during a channel change so that high output peaks are prevented. The TDA8840/8842 contain an automatic volume levelling (AVL) circuit which automatically stabilises the audio output signal to a certain level which can be set by the viewer by means of the volume control. This function prevents big audio output fluctuations due to variations of the modulation depth of the transmitter. The AVL function can be activated via the I2C-bus.

Synchronisation circuit

The sync separator is preceded by a controlled amplifier which adjusts the sync pulse amplitude to a fixed level. These pulses are fed to the slicing stage which is operating at 50% of the amplitude. The separated sync pulses are fed to the first phase detector and to the coincidence detector. This coincidence detector is used to detect whether the line oscillator is synchronised and can also be used for transmitter identification. The first PLL has a very high statical steepness so that the phase of the picture is independent of the line frequency.

The horizontal output signal is generated by means of an oscillator which is running at twice the line frequency. Its frequency is divided by 2 to lock the first control loop to the incoming signal. The time-constant of the loop can be forced by the I†C-bus (fast or slow).

If required the IC can select the time-constant depending on the noise content of the incoming video signal.

To protect the horizontal output transistor, the horizontal drive is immediately switched off when a power-on-reset is detected.

The drive signal is switched-on again when the normal switch-on procedure is followed.

Via the I2C-bus, adjustments can be made of the horizontal and vertical geometry. The vertical saw tooth generator drives the vertical output drive circuit which has a differential output current. For the EW drive a single ended current output is available.

When the horizontal scan is reduced to display 4 : 3 pictures on a 16 : 9 picture tube an accurate video blanking can be switched on to obtain well defined edges on the screen.

Overvoltage conditions can be detected via the EHT tracking pin. When an overvoltage condition is detected the horizontal output drive signal will be switched-off via the slow stop procedure but it is also possible that the drive is not switched-off and that just a protection indication is given in the IC-bus output byte. The choice is made via the input bit PRD.

Chroma and Luminance processing

The circuits contain a Chroma band pass and trap circuit. The filters are realised by means of gyrator circuits and they are automatically calibrated by comparing the tuning frequency with the X-tal frequency of the decoder.

The luminance delay line and the delay for the peaking circuit are also realised by means of gyrator circuits.

The centre frequency of the Chroma band pass filter is switchable via the I†C-bus so that the performance can be optimised for front-end signals and external CVBS signals.

During SECAM reception the centre frequency of the Chroma trap is reduced to get a better suppression of the SECAM carrier frequencies.

Colour Decoder

The decoder contains an alignment-free X-tal oscillator, a killer circuit and two colour difference demodulators. The 90° phase shift for the reference signal is made internally.

The IC contains an automatic colour limiting (ACL) circuit which prevents that oversaturation occurs when signals with a high Chroma-to-burst ratio are received. The ACL circuit is designed such that it only reduces the chroma signal and not the burst signal. This has the advantage that the colour sensitivity is not affected by this function. The base-band delay line is integrated in the PAL/SECAM IC s.

The demodulated colour difference signals are internally supplied to the delay line. The matrixed signals are externally available. The colour difference matrix switches automatically between PAL/SECAM and NTSC, however, it is also possible to fix the matrix in the PAL standard.

Which colour standard the IC can decode depends on the external X-tals. The X-tal to be connected to pin 34 must have a frequency of 3.5 MHz (NTSC-M, PAL-M or PAL-N) and pin 35 can handle X-tals with a frequency of 4.4 and 3.5 MHz. To prevent calibration problems of the horizontal oscillator the external switching between the 2 X-tals should be carried out when the oscillator is forced to pin 35. For a reliable calibration of the horizontal oscillator it is very important that the X-tal indication bits (XA and XB) are not corrupted. For this reason the X-tal bits can be read in the output bytes so that the software can check the I†C-bus transmission.

RGB output circuit and black-current stabilisation

The colour-difference signals are matrixed with the luminance signal to obtain the RGB-signals. The TDA 884X device has one linear RGB input. This RGB signal can be controlled on contrast and brightness.

The output signal has amplitude of about 2 volts black-to-white at nominal input signals and nominal settings of the controls.

To increase the flexibility of the IC it is possible to insert OSD and/or teletext signals directly at the RGB outputs.

This insertion mode is controlled via the insertion input (pin 26 in the S-DIP 56- and pin 38 in the QFP-64 level). This blanking action at the RGB outputs has some delay which must be compensated externally.

To obtain an accurate biasing of the picture tube a Continuous Cathode Calibration circuit has been developed.

This function is realised by means of a 2-point black level stabilisation circuit.

When the TV receiver is switched-on, the RGB output signals are blanked and the black current loop will try to set the right picture tube bias levels. Via the AST bit a choice can be made between automatic start-up or a start-up via the m-processor.

VIDEO SWITCH TEA6415C

In case of three or more external sources are used, the video switch IC TEA6415C is used. The main function of this device is to switch 8 video input sources on the 6 outputs.

Each output can be switched on only one of each input. On each input an alignment of the lowest level of the signal is made (bottom of sync. top for CVBS or black level for RGB signals).

Each nominal gain between any input and output is 6.5dB.For D2MAC or Chroma signal the alignment is switched off by forcing, with an external resistor bridge, 5VDC on the input. Each input can be used as a normal input or as a MAC or Chroma input (with external resistor bridge). All the switching possibilities are changed through the BUS.

Driving 75ohm load needs an external resistor. It is possible to have the same input connected to several outputs.

AM DEMODULATOR TDA9830

The TDA9830 is designed for AM-sound demodulation used in L and L standard.

Sound IF Input:

The sound IF amplifier consists of three AC-coupled differential amplifier stages each with approximately 20dB gain.

At the output of each stage is a multiplier for gain controlling. The overall control range is approximately -6 to +60dB and the frequency response (-3dB) of the IF amplifier is approximately 6 to 70MHz. The steepness of gain control is approximately 10mV/dB.

IF AGC:

The automatic gain control voltage to maintain the AM demodulator output signal at a constant level is generated by a mean level detector.The AGC-detector charges and discharges the capacitor at pin 3 controlled by the output signal of the AM-demodulator compared to an internal reference voltage. The maximum charge/discharge current is approximately 5 mA.

AM-demodulator

The IF amplifier output signal is fed to a limiting amplifier (two stages) and to a multiplier circuit.

However the limiter output signal (which is not any more AM modulated) is also fed to the multiplier, which provides AM demodulation (in phase demodulation). After lowpass filtering (fg @ 400kHz) for carrier rejection and buffering, the demodulator output signal is present at pin 6.

Audio Switch

This circuit is an operational amplifier with three input stages and internal feedback network determining gain (0dB) and frequency response (fg @ 700kHz). Two of the input stages are connected to pin 7 and pin 9, the third input stage to an internal reference voltage. Controlled by the switching pins 10 and 12, one of the three input stages can be activated and a choice made between two different AF signals or mute state. The selected signal is present at pin 8. The decoupling capacitors at the input pins are needed, because the internally generated bias voltage for the input stages must not be influenced by the application in order to avoid DC-plop in case of switching.

Reference Circuit:

This circuit is a band gap stabiliser in combination with a voltage regulation amplifier, which provides an internal reference voltage of about 3.6V nearly independent from supply voltage and temperature. This reference voltage is filtered by the capacitor at pin 4 in order to reduce noise. It is used as a reference to generate all important voltages and currents of the circuit. For application in 12V power supply concepts, there is an internal voltage divider in combination with a Darlington transistor in order to reduce the supply voltage for all IC function blocks to approximately 6V.

DIGITAL TV SOUND PROCESSOR TDA9875

The TDA9875 is a single-chip Digital TV Sound Processor. Supported standards are M, B/G, D/K, I and L.

Description of the demodulator and decoder section:

SIF Input:

Two input pins are provided, SIF1 e.g. for terrestrial TV and SIF2 e.g. for a satellite tuner. The selected signal is passed through an AGC circuit and then digitized by an 8-bit ADC operating at 24.576MHz.

AGC:

The gain of the AGC amplifier is controlled from the ADC output by means of a digital control loop employing hysteresis. The AGC has a fast attack behaviour to prevent ADC overloads and slow decay behaviour AGC oscillations. For AM demodulation AGC must be switched off.

Mixer

The digitized input signal is fed to the mixers, which mix one or both input sound carriers down to zero IF. A 24-bit control word for each carrier sets the required frequency.

FM and AM Demodulation

An FM or AM input signal is fed via a band-limiting filter to a demodulator that can be used for either FM or AM demodulation. Apart from the standard (fixed) de-emphasis characteristic, an adaptive de-emphasis is available for encoded satellite programs. A stereo decoder recovers the left and right signal channels from the demodulated sound carriers.

FM Identification:

The identification of the FM sound mode is performed by AM synchronous demodulation of the pilot signal and narrow-band detection of the identification frequencies. The result is available via the I†C-bus interface.

NICAM Demodulation:

The NICAM signal is transmitted in a DQPSK code at a bit rate of 728 kbit/s. The NICAM demodulator performs DQPSK demodulation and feeds the resulting bitstream and clock signal onto the NICAM decoder and, for evaluation purposes, to PCLK (pin 1) and NICAM (pin 2).

NICAM Decoder:

The device performs all decoding functions in accordance with the EBU NICAM 728 specification. After locking to the frame alignment word, the data is descrambled by applying the defined pseudo-random binary sequence; the device will then synchronise to the periodic frame flag bit C0.

The status of the NICAM decoder can be read out from the NICAM status register by the user. The OSB bit indicates that the decoder has locked to the NICAM data. The VDSP bit indicates that the decoder has locked to the NICAM data and that the data is valid sound data.

SOUND OUTPUT STAGE TDA2614/TDA2615/TDA2616Q

TDA2615 is used as the AF output amplifier for stereo applications. It is supplied by –12VDC coming from a separate winding in the SMPS transformer. An output power of 2*6W (THD=0.5%) can be delivered into an 8ohm load.

TDA2616Q is used as the AF output amplifier for stereo and dolby prologic applications. It is supplied by –16VDC coming from a separate winding in the SMPS transformer. An output power of 2*12W (THD=0.5%) can be delivered into an 8ohm load.

TDA2614 is used as the AF output amplifier for mono applications. It is supplied by –12VDC coming from a separate winding in the SMPS transformer. An output power of 2*6W (THD=0.5%) can be delivered into an 8ohm load.

VERTICAL OUTPUT STAGE WITH TDA8351/8356

The TDA8351/8356 vertical deflection circuit can be used in 90° and 110° deflection systems with field frequencies from 50 up to 120Hz. With its bridge configuration the deflection output can be DC coupled with few external components.

Only a single supply voltage for the scan and a second supply for the fly back are needed. The TDA8356 is intended for 90° systems and the TDA8351 is intended for 110° systems. The drive voltage is amplified by an amplifier and fed to two amplifiers, one is inverting and the other is a non inverting amplifier.

The outputs (pins 7 and 4) are connected to the series connection of the vertical deflection coil and feedback resistor Rsense (R702//R703). The voltage across Rsense is fed via pin 9 to correction amplifier, to obtain a deflection current which is proportional to the drive voltage. The supply voltage for the TDA8351/8356 is 15VDC at pin 3. The supply voltage generator has a separate supply voltage of 45VDC at pin 6.

VIDEO OUTPUT AMPLIFIER TDA6107Q

The TDA6107Q consists of three monolithic video output amplifiers. The amplifier can be seen as an operational amplifier with negative feedback.

The advantage of negative feedback is that the amplifier characteristics do not play an important role up to certain frequencies. The internal flash diodes protect the amplifiers against flash over in the picture tube. The only protections required at the cathode outputs are a flash resistor and a spark gap.

The TDA6107Q has an internal thermal protection circuit which gives a decrease of the slew rate at high temperatures.

Furthermore, the device needs only one power supply voltage (Vdd).

In contrast to previous types of DMOS video amplifiers, all the external resistors (Rf, Ri and Ra) are integrated, so the gain is fixed and saves 9 resistors.

Furthermore, the reference voltage is integrated, it saves a resistor divider and a decoupling capacitor. So, the replacement value of the TDA6107Q is very high.

The TDA6107Q is provided with a black current data pin. Since TDA884X is used as drive device, no adjustments are required for gain and black setting, as the TDA884X has I†C white point adjustment and black current set-up.

SINGLE/MULTISTANDARD VIF/SIF-PLL and FM-PLL/AM DEMODULATOR TDA9818

The TDA9818is an IC for multistandard vision IF signal processing, sound AM and FM demodulation.

It is a gain controlled wide band VIF-amplifier (AC-coupled). It is applicable for IF frequencies of 38.9 MHz, 45.75 MHz and 58.75 MHz. True synchronous demodulation is provided with active carrier regeneration. It has a VCO frequency which can be switchable between L and L accent (alignment external) picture carrier frequency. The TDA9818 has a SIF input for single reference QSS mode (PLL controlled). SIF AGC detector is to provide gain controlled SIF amplifier. The AM demodulator is without extra reference circuit. The supply voltage is +5VDC at pin 21.

COMBFILTER SAA4961

The SAA 4961 is a one-chip, PAL/NTSC comb filter IC with internal delay lines, filters, clock control, synchronisation and signal switches. The comb filter function is realised in a switched capacitor technique, so it has time discrete but amplitude continuous processing.

The Y/CVBS input is first clamped and then fed to the delay-line and comb filter section via a low pass pre-filter.

This filter can be bypassed via the external LPF-on pin. This pin is internally pulled up, to put the filter default on. The Y/CVBs input is also fed to the sync separator, where horizontal and vertical reference pulses are made.

Bypass mode can be forced via BYP (pin 3).FSC (pin 1) is the subcarrier input which is connected to the colour decoder. Input FSCSW pin indicates if fsc or 2*fsc is used.

The Sys1,2 pins (20, 23) indicate which system standard is processed. Sys2 is internally pulled up, Sys1 is internally pulled down.

Therefore when the Sys1,2 inputs are left open, automatically PAL 4.43MHz is forced.

SAA4961output pin 15 CVBS can be used for parallel-synced teletext decoders, to guarantee that the teletext display always has a correct timing relation with the main picture. Comb filter is disabled by setting SAA4961 pin 3 BYP high.

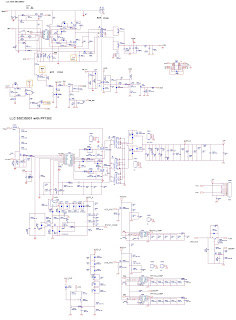

POWER SUPPLY (SMPS)

The DC voltages required at various parts of the chassis are provided by an SMPS transformer controlled by the IC MC44604 which is designed for driving, controlling and protecting switching transistor of SMPS. The transformer produces 150/115V for FBT input, –14V for audio output IC, S+5V for microcontroller, +15V for vertical output (field scan) and +33V for tuner and some other ICs and transistors.

MICROCONTROLLER SDA525X

The device is TV TEXT tuning and control system based on the SDA 525X TV TEXT microcontroller. It is designed for a low cost mono TV-SET with analogue picture and sound control. Neverthless the system offers an on screen display (OSD) and IR remote control of all functions.

SDA525X has the following features:

- Display of program number, channel number, TV standard, analogue values, sleep timer, parental control, and mute is done by OSD.

- Single LED for IR active, standby and on mode indication.

- 1 Control line to select external source.

- 3 Control lines for TV standard selection.

- Frequency synthesis tuning (62.5 kHz steps)

- 192 step fine tuning

- Channels corresponding to standards B/G, OIRT, L and I (I+)

- Mono sound control by analogue voltage

- System configuration with service mode.

SERIAL ACCESS CMOS 8K (1024*8) EEPROM ST24C08

The ST24C08 is a 8Kbit electrically erasable programmable memory (EEPROM), organised as 4 blocks of 256*8 bits.

The memory is compatible with the I†C standard, two wire serial interface which uses a bi-directional data bus and serial clock. The memory carries a built-in 4 bit, unique device identification code (1010) corresponding to the I†C bus definition. This is used together with 1 chip enable input (E) so that up to 2*8K devices may be attached to the I†C bus and selected individually.

CLASS AB STEREO HEADPHONE DRIVERTDA1308

The TDA1308 is an integrated class AB stereo headphone driver contained in a DIP8 plastic package. The device is fabricated in a 1 mm CMOS process and has been primarily developed for portable digital audio applications.

SAW FILTERS

Saw filter type : Model:

G1965M : PAL-SECAM B/G MONO

G3962M : PAL-SECAM B/G GER&NIC STEREO, PAL I NIC STEREO, INT-1

G1984 : PAL-SECAM B/G GER&NIC STEREO INT-2

J1951M : PAL-I MONO

J3950M : PAL-I NIC STEREO

J1956M : PAL-I MONO

K2955M : PAL-SECAM B/G-D/K MONO, PAL-SECAM B/G-D/K-I, MONO, PAL-SECAM B/G-D/K-L MONO

K2958M : PAL-SECAM B/G-D/K (38) MONO

K2962M : PAL-SECAM B/G-L/L MONO

G3957M : PAL-SECAM B/G-L/L GER&NIC BG/L STEREO

K6256K : PAL-SECAM B/G-D/K-I-L/L MONO, PAL-SECAM B/G-D/K-I, L/L GER&NIC BG/L STEREO,

PAL-SECAM B/G-D/K-I-L/L I, NICAM STEREO, PAL-SECAM B/G-D/K-I-L/L GER&NIC I B/G-L, STEREO

K6259K : PAL-SECAM B/G-D/K-I-M/N (EURO) MONO

M1963M : PAL M/N MONO, NTSC M MONO, PAL M/N-NTSC M MONO

BTSC STEREO/SAP/DBX-DECODER and AUDIO PROCESSOR TDA9855

The TDA9855 is a BTSC stereo/SAP/dbx decoder and audio processor. It performs all functions to transform the composite baseband signal into the appropriate audio output signals to line out and to the loudspeaker output stages.

TDA8840/8842/8844:

The TDA884X is IýC-bus controlled single chip TV processor which is intended to be applied in PAL, NTSC, PAL/NTSC and multi-standard television receivers. These IC s are nearly pin compatible with the TDA837X TV processors but have a higher degree of integration because the delay line (TDA4665 function) and the SECAM decoder have been integrated. In addition to these functions some additional features have been added like Continuous Cathode Calibration (2-point black current loop which results in an accurate biasing of the 3 guns), adjustable luminance delay time, blue stretching and dynamic skin tone control. General description of UV1315:

The UV1315 tuner belongs to the UV 1300 family of tuners, which are designed to meet a wide range of applications.

It is a combined VHF, UHF tuner suitable for CCIR systems B/G, H, L, L, I and I. The low IF output impedance has been designed for direct drive of a wide variety of SAW filters with sufficient suppression of triple transient. The UV1316 tuner belongs to the UV 1300 family of tuners, which are designed to meet a wide range of applications.

It is a combined VHF, UHF tuner suitable for CCIR systems B/G, H, L, L, I and I. The low IF output impedance has been designed for direct drive of a wide variety of SAW filters with sufficient suppression of triple transient.

TEA6415C:

General Description:

The main function of the TEA6415C is to switch 8 video input sources on the 6 outputs. Each output can be switched to only one of the inputs whereas but any same input may be connected to several outputs.

All switching possibilities are controlled through the I2C-bus.

TDA9830:

General description:

The TDA9830, a monolithic integrated circuit, is designed for AM-sound demodulation used in L- and L-standard. The IC provides an audio source selector and also mute switch.

TDA2614/TDA2615/TDA2616Q:

General Description of TDA2614:

The TDA2614 is a power amplifier in a 9-lead single-in-line (SIL9) plastic medium power package. It has been especially designed for mains fed applications.

General Description of TDA2615:

The TDA2615 is a dual power amplifier in a 9-lead single-in-line (SIL9). It has been especially designed for mains fed applications.

General Description of TDA2616Q:

The TDA2616Q is a dual power amplifier. It is supplied in a 9-lead SIL-bent-to DIL plastic power package (SOT157). It has been especially designed for mains fed applications.

TDA8351/8356:

General Description:

The TDA8356 is a power circuit for use in 90ł colour deflection system for field frequencies of 50 to 120 Hz. The circuit operates as a highly efficient class G system.

The TDA8351 is a power circuit for use in 110ł colour deflection system for field frequencies of 50 to 120 Hz. The circuit operates as a highly efficient class G system.

TDA6107Q:

The TDA6107Q includes three video output amplifiers in a SIL 9 MP (Single In Line 9 pins Medium Power) package SOT111BE, using high-voltage DMOS technology, and is intended to drive the three cathodes of a colour picture tube.

In contrast to previous types of DMOS video amplifiers, all external resistors (Rf, Ri and Ra) are integrated, so the gain is fixed and it saves 9 resistors.

To obtain maximum performance, the amplifier should be used with black-current control and mounted on the CRT panel.

SAA4961:

The SAA4961 is an adaptive alignment-free one chip comb filter compatible with both PAL and NTSC systems and provides high performance in Y/C separation.

It is possible to switch the comb filter into one of the following 3 modes:

1. Comb mode : In this mode, luminance and chrominance comb filter function are active. Chrominance output pin (pin 12) outputs comb filtered chrominance signal, luminance output pin (pin 14) outputs comb filtered luminance signal and CVBS output pin (pin 15) outputs delay compensated CVBS signal.

2. Comb off mode : In this mode, luminance comb filter function is turned off, but chrominance comb filter function operates. Chrominance output pin (pin 12) outputs comb filtered chrominance signal, luminance output pin (pin 14) outputs delay compensated CVBS signal and CVBS output pin (pin 15) outputs delay compensated CVBS signal.

3. Bypass mode: In this mode, no IC-function is active. Cext is bypassed to chrominance output pin (pin 12) and Yext/CVBS is bypassed to luminance output pin (pin 14) and CVBS output pin (pin 15).

MC44604:

General description:

The MC44604 is an enhanced high performance controller that is specifically designed for off-line and DC-to-DC converter applications. It offers a really safe and reliable power management thanks particularly to its protection features (foldback, overvoltage detection, soft start, accurate demagnetization detection). Its high current totem pole output is also ideally suited for driving a power MOSFET, but can also be used for driving a bipolar transistor in low power converters. In addition to these features, the MC44604 offers an efficient stand-by mode.

SDA525X:

General description:

The SDA525X is designed for a low cost mono TV-set with analogue picture and sound control. IN SDA525X the following IC s are used and supported:

Non-volatile memory : SDA 2526 or SDA2546

PLL : SDA 3202-3, SDA 3302

IR transmitter: SDA 2208-3 or SDA 2218

IR preamplifier: SFH 506-32

TDA9875:

General description:

The TDA9875 is a single-chip Digital TV Sound Processor (DTVSP) for analogue and digital multi-channel sound systems.

TDA9818:

General description:

The TDA9818 is an integrated circuit for multistandard vision IF signal processing, sound AM and FM demodulation.

ST24C08:

The ST24C08 is a 8Kbit electrically erasable programmable memory (EEPROM), organized as 4 blocks of 256 * 8 bits. The memory operates with a power supply value as low as 2.5V. Both Plastic Dual-in-Line and Plastic Small Outline packages are available.

TDA9855

General description:

The TDA9855 is a bipolar-integrated BTSC stereo/SAP decoder with hi-fi audio processor (IýC-bus controlled) for application in TV sets.

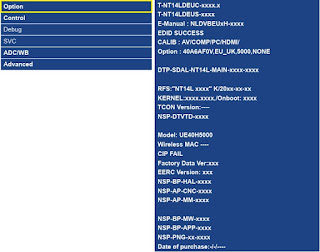

11AK19 CHASSIS MANUAL ADJUSTMENTS PROCEDURE

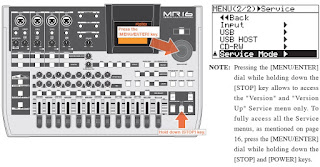

In order to enter the service mode, first enter the installation menu (or press blue button on the remote control handset) and then press the digits4, 7, 2 and5respectively.

For ADJUST settings:

Select Adjust using DN or UP button and press RIGHT or LEFT button to enter it. To select different adjust parameters, use DN or UP button. To change the selected parameter, use LEFT or RIGHT button.

WHITE BALANCE ADJUSTMENT:

The following three parameters are used to make white balance adjustment. To do this, use a Colour Analyser. Using white point RED, white point GREEN and white point BLUE parameters, insert the + sign in the square which is in the middle of the screen.

ADJUST 00 = White Point RED

ADJUST 01 = White Point GREEN

ADJUST 02 = White Point BLUE

AGC ADJUSTMENT:

In order to do AGC adjustment, enter a 60dBmV RF signal level from channel C-12.

Connect a digital voltmeter to pin 1 of the tuner. Change the AGC parameter until you see 3.70VDC on voltmeter display. Check that picture is normal at 90dBmV signal level.

IF-PLL NEGATIVE ADJUSTMENT (Only with PLL tuner):

Connect 38.9 MHz test pattern for PAL B/G, PAL-SECAM B/G, 39.5 MHz test pattern for PAL I or 45.75 MHz test pattern for PAL M/N, NTSC M model to Z401 SAW filter input terminals. Change the IF-PLL Negative parameter until you see IN, DOWN below. If you cannot catch IN, DOWN position this way, using a screwdriver rotate the VIF-COIL LT401 left or right until you see IN, DOWN.

IF-PLL POSITIVE ADJUSTMENT (Only with PLL tuner):

Connect 33.9 MHz test pattern for SECAM L model to Z401 SAW filter input terminals. Change the IF-PLL Positive parameter until you see IN, DOWN below. If you cannot catch IN, DOWN position this way, using a screwdriver rotate the VIF-COIL LT401 left or right until you see IN, DOWN.

LUMINANCE DELAY ADJUSTMENT (with only TDA 8844 video processor):

Y-Delay PAL

Enter a PAL B/G colour and black-white bar test pattern via RF. Adjust Y-Delay PAL till the colour transients on the colour bar of the pattern become as sharper and colours between transients do not mix with each other as possible.

Note: If the SAW filter is one of the G1965M, J1951M, J3950M, K2958M, K2962M, G3957M, K6256K, K6259K or M1963M, there is constant group delay distortion, so for an equal delay of the luminance and chrominance signal the delay must be set at a value of 160nS. This means the adjustment must be set to the maximum value.

Y-Delay SECAM

Enter a SECAM B/G colour and black-white bar test pattern via RF. Adjust Y-Delay SECAM till the colour transients on the colour bar of the pattern become as sharper and colours between transients do not mix with each other as possible.

Note: If the SAW filter is one of the G1965M, K2958M, K2962M, G3957M, K6256K or K6259K, there is constant group delay distortion, so for an equal delay of the luminance and chrominance signal the delay must be set at a value of 160nS. This means the adjustment must be set to the maximum value.

Y-Delay NTSC

Enter an NTSC colour and black-white bar test pattern via RF. Adjust Y-Delay NTSC till the colour transients on the colour bar of the pattern become as sharper and colours between transients do not mix with each other as possible.

Note: If the SAW filter is M1963M, there is constant group delay distortion, so for an equal delay of the luminance and chrominance signal the delay must be set at a value of 160nS. This means the adjustment must be set to the maximum value.

Y-Delay Other

In case of other colour systems, enter this system with colour and black-white bar test pattern via RF. Adjust Y-Delay Other till the colour transients on the colour bar of the pattern become as sharper and colours between transients do not mix with each other as possible. Normally for an equal delay of the luminance and chrominance signal the delay must be set at a value of 160nS. This means the adjustment must be set to the maximum value.

VERTICAL ZOOM ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G circle test pattern via RF. Change vertical zoom till you see the upper and lower limit of the circle as close to the upper and lower limit of the picture tube as possible.

VERTICAL SCROLL ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G circle test pattern via RF. Change vertical scroll till you see the circle exactly in the middle of the screen.

HORIZONTAL SHIFT ADJUSTMENT:

Enter a RED PURITY test pattern via RF.Change horizontal shift till the picture is horizontally centred. Check whether this adjustment is correct after completing Service Mode Adjustment.

VERTICAL SLOPE ADJUSTMENT:

Enter a CROSS-HATCH B/G test pattern via RF. Change vertical slope till the size of squares on both the upper and lower part of test pattern become equal to the squares laying on the vertical centre of the test pattern. Check and readjust VERTICAL SLOPE item if the adjustment becomes improper after some other geometric adjustments are done.

VERTICAL AMPLITUDE ADJUSTMENT:

Enter a PAL B/G test pattern via RF. Change vertical slope till horizontal black lines on both the upper and lower part of the test pattern become very close to the upper and lower horizontal sides of picture tube and nearly about to disappear. Check and readjust VERTICAL AMPLITUDE item if the adjustment becomes improper after some other geometric adjustments are done.

S-CORRECTION ADJUSTMENT:

Enter a PAL B/G circle test pattern via RF. Change S-correction till the middle part of the circle is as round as possible.

VERTICAL SHIFT ADJUSTMENT:

Enter a PAL B/G test pattern via RF. Change Vertical Shift till the test pattern is vertically centred, i.e. horizontal line at the centre pattern is in equal distance both to upper and lower side of the picture tube. Check and readjust Vertical Shift item if the adjustment becomes improper after some other geometric adjustments are done.

EW WIDTH ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Width till the vertical black and white bars on both left and right side of the pattern exactly disappear.

EW PARABOLA WIDTH ADJUSTMENT (only for 110ł picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Parabola Width till vertical lines close to the both sides of the picture frame become parallel to vertical sides of picture tube. Check and readjust EW Parabola Width item if the adjustment becomes improper after some other geometric adjustments are done.

EW CORNER PARABOLA ADJUSTMENT (only for 110ł picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Corner Parabola till vertical lines at the corners of both sides of picture frame become vertical and parallel to vertical corner sides of picture tube. Check and readjust EW Corner Parabola item if the adjustment becomes improper after some other geometric adjustments are done.

EW TRAPEZIUM ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Trapezium till vertical lines, especially lines at the sides of the picture frame became parallel to the both sides of picture tube as close as possible. Check and readjust EW Trapezium item if the adjustment becomes improper after some other geometric adjustments are done.

16:9 HORIZONTAL SHIFT ADJUSTMENT:

Enter a RED PURITY test pattern via RF.Change horizontal shift till the picture is horizontally centred. Check whether this adjustment is correct after completing Service Mode Adjustment.

16:9 VERTICAL SLOPE ADJUSTMENT:

Enter a CROSS-HATCH B/G test pattern via RF. Change vertical slope till the size of squares on both the upper and lower part of test pattern become equal to the squares laying on the vertical centre of the test pattern. Check and readjust VERTICAL SLOPE item if the adjustment becomes improper after some other geometric adjustments are done.

16:9 S-CORRECTION ADJUSTMENT:

Enter a PAL B/G circle test pattern via RF. Change S-correction till the middle part of the circle is as round as possible.

16:9 VERTICAL SHIFT ADJUSTMENT:

Enter a PAL B/G test pattern via RF. Change Vertical Shift till the test pattern is vertically centred, i.e. horizontal line at the centre pattern is in equal distance both to upper and lower side of the picture tube. Check and readjust Vertical Shift item if the adjustment becomes improper after some other geometric adjustments are done.

16:9 EW WIDTH ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Width till the vertical black and white bars on both left and right side of the pattern exactly disappear.

EW PARABOLA WIDTH ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Parabola Width till vertical lines close to the both sides of the picture frame become parallel to vertical sides of picture tube. Check and readjust EW Parabola Width item if the adjustment becomes improper after some other geometric adjustments are done.

16:9 EW CORNER PARABOLA ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Corner Parabola till vertical lines at the corners of both sides of picture frame become vertical and parallel to vertical corner sides of picture tube. Check and readjust EW Corner Parabola item if the adjustment becomes improper after some other geometric adjustments are done.

16:9 EW TRAPEZIUM ADJUSTMENT (only for 110 picture tubes):

Enter a PAL B/G test pattern via RF. Change EW Trapezium till vertical lines, especially lines at the sides of the picture frame became parallel to the both sides of picture tube as close as possible. Check and readjust EW Trapezium item if the adjustment becomes improper after some other geometric adjustments are done.