Factory Menu & Main Menu, How to Enable Factory hotkey

Follow the below steps to pop-up the Factory menu in case of “Factory hotkey” is disabled:

Enable Factory hotkey method:

Method one:

* Press RCU “MENU” key to display main menu

* Select “SettingsàPictureàAdvanced settingà Contrast”, Scroll down to “Contrast” item

* Press the subsequence RCU keys “9”, “7”, “3” and “5”

* Select “9-Sita P mode”, Press RCU “◄/►” key change the values to ON

* Reboot TV

* 'Factory Hotkey' will be ON automatic.

Method two:

* Create a file named 'sita-P' with no suffix, note the capitalization.

* Put the file 'sita-P' into the U disk, delete all PKG and BINC files.

* Put the U disk into the TV.

* Power on TV by AC, at the same time press “power on” key which on the boardfor 10s until the TCL logo show.

* 'Factory Hotkey' will be ON automatic.

If “Factory hotkey” is enabled, just press RCU “Return” keyto pop-up again the Factory menu.

The status of “Factory hotkey” can be changed in “Factory menu->Factory hotkey”

Press RCU Ok►”key to enter the submenu.

Press RCU “Menu” key to go back to the root menu.

Press RCU “◄/►” key to change the values.

Press RCU “OK” key run the function.

Press RCU “Exit” key exit the Factory menu.

Factory Captions Description

While “Factory hotkey” is enabled, there’re some toggled display information (~2s) relative to SW, ProjectID, CI+, Network ID to facilitate 100% quick screening without accessing to whatever else menu:

MV (Main SW Version)

ID (Project ID)

Panel ID

MEMC (FRC SW Version)

MID(Internet info for factory)

P (Production - Factory mode flag) S (Factory UART Parser mode flag) W (Warm-Up mode flag)

How to enter Main Menu

* Press RCU “MENU” key to display main menu

* Select “Settings>Picture>Advanced setting> Contrast”, Scroll down to “Contrast” item

* Press the subsequence RCU keys “1”, “9”, “5” and “0”

* Then the Main Menu will be displayed on the screen.

Warm-up Test

Following TCL standard and practices, it’s required minimum 15min of Warm-Up that can be considered as Burn-In.

Additional Aging for White Balance alignment is no more necessary due to consistent Picture Performance with Cloning usage.

First you need to enable Factory Key. After that selecting“ Factory menu >WARM UP”, pressing RCU “OK ►” key and then leaving Factory menu by pressing “Exit” key. To release/disable Burn-in mode, it’s just required to press “Menu” button from local keyboard. Other faster methods via UART/IR commands are available on enclosed SIACP

requirements (rev. v8.31)

White Balance & Automatic Gamma correction

For the white balance & automatic gamma correction, we only need do one of them based on the value of

Align-mode in PDM system or the method gave by AOE or R&D.

The detail instruction of Align-mode is as below table:

Align mode WB alignment of Auto gamma correction 0 > WG alignment

1 > Gamma correction

White Balance alignment (Golden sample)

As some color coordinates discrepancies can be noticed from panel batches to others, it may necessary to perform slight touch-up.

For Color temperature adjustment, switch TV on leading HDMI input where should be connected suitable generator providing following format 1280x720p@60Hz test pattern. A 32 steps grey scale is recommended to assess relevant colorimetry tracking and low or high light saturation points.

![]()

Ensure that TV’s picture enhance is off.

Ensure that TV is in Factory mode to access to” White Balance” adjustment submenu.

WB Normal is the first mode which is adjusted in HDMI source,the next are HDMI warm and cool mode.

Warm and Cool Tone are relatives to Normal mode. WB adjust need to fix default G Gain .Offset registers needn’t to be adjusted.

“Gain” registers set need to be adjusted at 70IRE.

Note: The operation must enable factory “P” mode

Auutomatic Gamma correction

Gamma correction, or often simply gamma, is the name of a nonlinear operation used to encode and decode luminance or tristimulus values in video or still image systems.

You need adjust 4+3 gamma for different samples based on the color coordinates and target gamma offered by PQ engineer. So each sample can get almost the same effect as PQ golden sample. The 4+3 gamma include 4 gamma based on 4 different color temperature (cool, normal, warm1, warm2) and 3 gamma related to SDR to HDR (cool, normal, warm).

For the automatic gamma correction, we can do as below, but please refer to “Gamma correction specification (v1.00)”for detail.

* Initialize the picture, turn off dynamic backlight, dynamic contrast, and set picture mode as computer desktop mode;

* Get the color coordinates (x, y, Y) and target gamma in the PDM of the target model;

* Open the factory menu of TV, Open the tools SIACP and main.vi on the PC, connect the equipment correctly (CA310, serial port, PC, TV);

* Fill the color coordinates (x, y, Y) target gamma, error range and time-delay in the main.vi tool that made by AOE, and save it;

![]()

Put the probe on the middle of the panel, and then run main.vi. The 4+3 gamma will be created and calibrated automatically and saved in the TV.

As 4+3 gamma is a new and good way for PQ especially for HDR, we need adjust it in the factory now. And if we do the 4+3 gamma, there is no need to adjust the white balance. But we need do the initial setup of white balance.

“How to do initial setup of white balance”

Note: The operation must enable factory “P” mode

Targets and Tolerances for all inputs

(According to company uniform LED color temperature standard of panel)

The measured and adjustable parameters should be mainly “x”, “y” coordinates.

The White Balance alignment and Automatic Gamma correction should be performed using a well calibrated and contact less analyzer (ex: Minolta CA210 or CA310). The analyzer may not touch the screen surface, and measurement must be performed in a dark environment keeping the probe(s) at 90+/-2° from the panel centre.

The results should fulfil specification for each TV set offered by R&D and below tolerances:

For the 4+3 gamma the target value is 2.2 and error range is ± 0.05.

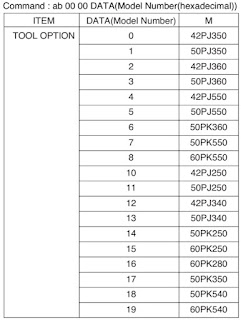

Note:We will add more project ID later.

Note: If we can do both of White Balance & Automatic Gamma correction. For some special models, please notice the information provided by Huizhou factory or PJM to choose which way to make it.

Cloning

Once a TV is well aligned and prepared (channels maps, volume, picture presets, …) , user can prepare golden clone image that can be copied on demand to all further TV production lot of same TV. To access cloning function, you can select “Factory menu USB Clone >All -Chanel List - EEPROM - Users Setting” , Scroll down to “TV to USB” or “USB to TV” and press RCU “OK ►” key to process. 4 BIN images can created, overwritten or read on USB stick (pen drive) depending on chosen template like following: “database-applications-database-***.db” . These files need to be used strictly with MT58SoC platform as depending on SW structure.

Other faster access methods via UART/IR command share available on enclosed SIACP requirements (rev. v8.31).

Note: This function is only useful on factory sita P mode. And in hotel mode, we can use it too, but only copy the information related to the hotel.

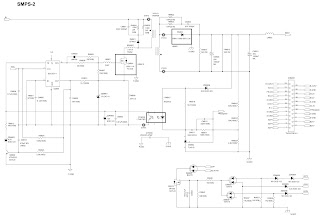

High Pot. and Insulating Resistance Tests

At the end of the process, a “High Voltage” and an “Insulating Resistance” tests are required to fulfil Safety

Electrical requirements (CEI 65065).

High Voltage Withstanding requirements --Insulating Resistance requirements

“Voltage” > 3500VAC - “Voltage” > 500VDC

“Max Leakage Current” > 10 mA - “Threshold Min” >4M Ω

“Test Time” >3 sec - “Test Time” >2 sec

At final process stage, it’s necessary to perform “Reset shop” before any packing to leave Factory mode and restore User default presets.

First you need to enable Factory Key. After that selecting “Factory menu àReset Shop”, then pressing RCU “OK ►” key. Other faster methods via UART-IR commands are available on enclosed SIACP requirements (rev. v8.31).

Note:A password might be required in case of Parental Control function is locked, use default “1234” password or “0423” super password to clean-up existing ones if forgotten.

“How to upgrade main SW using tool”

Upgrade RT2841 main SW by using RTK tool

Download boot bin “dvrboot.rescue.exe.bin.bin” &main software “Update.img” from the software route.

Connect UART interface to suitable manufacturing TV input connector, upgrade boot bin first to blank IC.

1) Turn off your TV, and then connect the Serial Interface to USB debug port.

2) Open the rtice software, select the Burn page, click the icon, and enter the boot burn page as shown below

3) Click the settings icon, open the settings page, and configure it as shown below

Connect Type select RS232;

Comm port selects the corresponding serial port;

Set-Status type option ROM Code;

IC Type Selection Macarthur5;

Then click ok.

4) Configure Burn parameters and select bootcode load path, as shown below.

5) Click the Start button to enter the boot state and the state will change to the connect state as shown above.

6) Then power on the TV. After the connection is successful, the TV enters the upgrade state and waits for the upgrade to complete. After the upgrade is complete, the following figure shows the bootcode successfully burned.

Then Upgrade Main SW , Copy Main SW “Update.img” into USB stick (pen drive) root path,

> Insert USB to TV USB port, long press the “MENU-STB” button of local keyboard , and then Power on TV by AC, The light of IR will flicker, it means TV is updating SW.

> After finish update SW, TV will reboot automatically and please remove the USB.

“How to upgrade SW using USB”

Upgrade RT2841 main SW

* Copy the “Update.img” into USB stick (pen drive) root path.

* Please delete other xxx.img files from USB stick.

* Plug USB stick to the TV.

* Power on TV by AC, at the same time press “power on” key for 10s, TV will update SW automatically.

* When reflashing is successful, TV should restart automatically (about 4min).

Note:If “upgrade” was performed, a “Welcome Setup” menu should be displayed, otherwise new SW version should be displayed into relevant Factory mode caption info or on bottom of “Factory menu“

If the P mode is reflashing after upgrade and can not be closed, go to “Factory menu” and select ‘Sita P mode’ to ON, restart TV. Then go to “Factory menu” again and select ‘Factory hotkey’ to OFF.

“How to upgrade SW using USB and RCU”

“How to upgrade FLASH SW by OAD”(not support now)

“How to change Project ID with RCU”

Enable Factory Key (See “section 2.0-Product Assembly”)

* Process following subsequence IR codes to change project ID: (xxx: Project ID, ex: 001)

If it works, the TV will restart automatically.

“How to upgrade CI Key using USB”

* Enable Factory Key

* Create the folder named “CIKEY”, change the CI key to “CIKEY-xxx.bin” (xxx is the number), put CI key into the folder.

* Plus the USB into the TV.

* Go to “Main menuàService menuàUSB Update >CI Key Upgrade “, click the right button.

* If the toast show CI Update OK, it means burn the key success.

After burning, the CI key will movie to the folder CIKEY>BACKUP.

Note: The operation must enable factory “P” mode

Note: If unfortunately the process failed, you may need to download new CI key and repeat operation again.

“How to upgrade Widevine Key using USB”

* Enable Factory Key

* Create the folder named “WIDEVINEKEY”, change the Widevine key to “WIDEVINE-xxx.bin”(xxx is the number), put Widevine key into the folder.

* Plus the USB into the TV.

* Go to “Main menuà > Service menu > USB Update > Widevine Key Upgrade “, click the right button.

* If the toast show Widevine Update OK, it means burn the key success.

* After burning, the Widevine key will movie to the folder WIDEVINEKEY-BACKUP.

Note: The operation must enable factory “P” mode

“How to upgrade HDCP key using USB”

HDCP

* Create the folder named “HDCP”, change the HDCP key to “HDCP-xxx.bin”(xxx is the number), put HDCP key into the folder.

* Enable Factory Key

* Plus the USB into the TV.

* Go to “Main menu > Service menu > USB Update >[HDCP] Upgrade“, click the right button.

* If the toast shows HDCP Update OK, it means burn the key success.

After burning, the HDCP key will movie to the folder HDCP-BACKUP

“How to upgrade MAC Address using USB”

* Create the folder named “MAC”, change the MAC key to “MAC-xxx.bin”(xxx is the number), put MAC key into the folder.

* Enable Factory Key

* Plus the USB into the TV.

* Go to “Main menu>Service menu> USB Update > MAC Upgrade“, click the right button.

* If the toast show MAC Update OK, it means burn the key success.

* After burning, the MAC key will movie to the folder MAC-BACKUP.

Note: There is no this function which is only displaying.

“Network Connection Setup”

Note:You can set up your TV so that it can access the Internet through your local area network (LAN) using a wired or wireless connection.

Wired Network Connection

You can connect your TV to your LAN using cable in three ways:

1) Plug your TV to your LAN by connecting the LAN port on your TV to an external modem using a Cat5 cable.

2) Plug your TV to your LAN by connecting the LAN port on your TV to an IP Sharer which is connected to an external modem. Use Cat5 cable for the connection

3) Depending on how your network is configured, you may be able to plug your TV to your LAN by connecting the LAN port on your TV directly to a network wall outlet using a Cat5 cable (Note that the wall outlet is attached to a modem or router elsewhere in your house)

4) Select “Menu >Network Settings>Ethernet” to check if the network has connected. If not then select “IP settings” to connect to network.

Wireless Network Connection

To connect your TV to your wireless network, you need a wireless router or modem and a Wireless LAN Adapter.

* Select “Menu > Network Settings> Wi-Fi-On”, then it will appear the valid wireless networks near your area.

* Select available access point and press “OK ►” to connect the TV to it.

Note: If you select a protected access point, you will have to enter the corresponding password. Press “OK” on the remote control to display virtual keyboard to enable you to enter the password.

Network Setup

* Connect your TV and the available network with the network cable first.

Press on the remote control and select “Network Settings > Ethernet” to check if the network has connected.

If connected, the Internet connection will display Connected. If not, If not it will display “Not Connected” and you can try to enter your IP address manually to connect the network follow below steps

* Select “Advanced options”>“IP Settings”>“Static” by pressing “OK ►” key

* Enter the “IP address”, “Gateway”, “Network prefix length”, “DNS1”and “DNS2”values. Use remote control digital keys to enter number sand “◄/►” key to move from one to other field location

* After setting all required inputs and save successful, to check the Internet connectivity again

* Select then press “OK ►” key to display current connection details, such as Internet connection status, IP address, MAC address etc

“How to do initial setup of white balance”

Firstly, you need to enable Factory Key:

* Press RCU “MENU” key to display main menu

* Select “Settings →Picture → Advanced setting → Contrast”, Scroll down to “Contrast” item

* Press the subsequence RCU keys “9”, “7”, “3” and “5”

* Select “9-Sita P mode”, Press RCU “◄/►” key change the values to ON

* Reboot TV

* 'Factory Hotkey' will be ON automatic.

Secondly, press RCU Option, Select Picture → Advanced setting → Contrast → Press RCU “1950” enterdesign main menu → Reset all