SERVICE MODE ENTRY METHODSTOSHIBA – 2989UE / 2989UH / 2989XP

Entering into service mode

Press [Mute] button once on the remote control handset.

Once again press and hold remote handset [mute] button.

While keeping the Mute] button pressed, press [Menu] button on TV set.

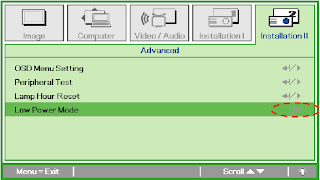

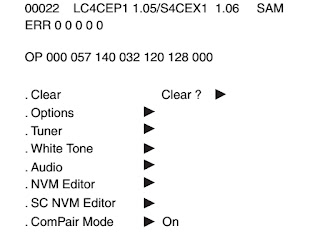

Displaying the adjustment menu

Press [menu] button on the TV set to shift from adjustment mode to service mode and vice versa.

Service mode keys

Select adjustment item by pressing the [channel+] or [channel-} button on the remote control handset.

Adjust data value by pressing the [Volume+] or [Volume-] button on the remote control handset.

Cancellation of service mode

To return to normal TV mode, press Power] / [Standby] button to turn off TV once

Service mode adjustments

Following adjustments items will appear on the screen.

Item Name of adjustment Reference data

R CUT R CUTOFF B/W 40H

G CUT G CUTOFF 40H

B CUT B CUTOFF 40H

GDRV G DRIVE 40H

BDRV BLUE DRIVE 40H

CNTX SUB-CONTRAST MAX(4:3 MODE) 7FH

BRTC SUB BRIGHT CEN 7FH

COLC SUB COLOR CEN NTSC 39H

TNTC SUB TINT GEN 40H

COLP SUB COLOUR CEN PAL 39H

COLS SUB COLOUTR CEN SECAM 27H

SCOL SUB COLOUR 13H

SCNT SUB CONTRAST 2H

VOLS VOL SCART 75H

FVOL FM VOL PRE SCALE 15H

NVOL NICAM VOL PRE SCALE 3AH

NICL NICAM THRESHOLD LEVEL 03H

NICH NICAM THRESHOLD LEVEL 0AH

IDL IGR THRESHOLD LEVEL 04H

IDH IGR THRESHOLD LEVEL 0EH

EVOL EXT PRE VOLUME 01H

EMX NICAM ON LEVEL FCH

EMN NICAM ON LEVEL 64H

FMA FM ATTENNUATOR LEVEL 00H

STS STEREO SEPERATION 00H

HPOS 50HZ HORIZONTAL POSITION FEH

VPOS V-POSITION 0DH

HIT HEIGHT 3EH

VLIN V-LENEARITY 17H

VSC V-S CORRECTION 18H

VPS V-SHIFT 0CH

VCP V-COMPENSATION 07H

WID PICTURE WIDTH 18H

PARA E-W PARABOLA 22H

CNR E-W CORNER 04H

TRAP TRAPEZIUM 0FH

HCP H-COMPENSATION 01H

VFC V-F CORRECTION 0FH

BELL SECAM BELL FILTER 80H

SRY SECAN R-Y 08H

INITILIZATION OF MEMORY DATA OF QA02

After replacing IC the following initialization is required.

Enter the service mode then select any register item.

Press and hold the [call] button on the remote then press the [channel+] button on the TV. The initialization of IC has been completed.

Check the picture carefully. If necessary, adjust any adjustment item as explained below.

Perform auto search memory as explained in the owner’s manual.

CAUTION:- Never attempt to initialize the data unless memory IC has been replaced.

Test signal selection

In the service mode, pressing of [AV] / [Video] button shows the test patterns on screen. Every pressing of [AV] / [Video] button cycle through 14 NTSC test patterns and 14 PAL test patterns.

Some of the test patterns are:

Red single colour, green single colour, blue single colour

Black single colour, white single colour

White balance adjustment pattern

Black cross- bar, white crossbar

Black crosshatch, white cross hatch

Black cross dot, white cross dot, h signal etc.

White balance adjustment

Cutoff adjustment [RCUT] [GVUT] [BCUT]

Drive adjustment [GDRV] [BDRV]

- Set contrast to 40, and brightness to +20 by picture control.

- Set the TV in service mode, and get the inside W/B adjustment signal with [AV/Video] button.

- Select R CUT, G CUT, AND B CUT with [Channel+/-] buttons, to set individual values to 32, and to set GDRV and BDRV to 20 with [Volume+/-] buttons.

- Press [-/--] button on the remote control and rotate screen VR to get one slight horizontal line on screen.

- Every pressing of [-/--] button provides horizontal line picture and o\normal picture alternately.

- Press [-/--] button to release horizontal line picture, and select the two other colours which did not light in the above step with [CHANNEL+/-]. Then tap [Volume+/-] buttons so that three colors slightly light in the same level..

- To correct white balance in light area, select GDRV and BDRV with [CHANNEL+/-] buttons to adjust.

- To correct white balance in dark area, perform fine adjustment to RCUT, GCUT and BCUT.

Self-diagnostic function.

- Press [9] button on the remote control during display of adjustment menu.

- The diagnosis will begin to check if interfaces among ICs are executed properly.

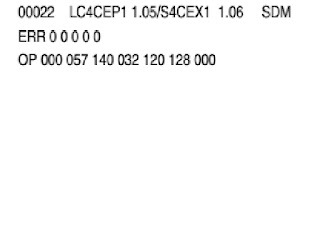

During diagnosis the following displays are shown.

-----------------------------------------------------------------------

<Self check>

2390****

power 00

bus line OK

bus cont OK

block UV V1 V2

QV01

------------------------------------------------------------------------

Values 1-5 are explained below

Part number of micro control

- Operation number of protecting circuit-“00” is normal. When indication is other than “00”, over-current apts to flow, and circuit parts may possibly damaged.

BUS LINE CHECK OK NORMAL

“SDA 1- GND” means that SDA line is shorted to ground

“SCL - GND” means that SCL line is shorted to ground.

“SCL 1-SDA 1” means that SDA line is shorted to SCL line

bus cont “OK” is normal

When indication shows “Q000 NG”, the device with the number may possibly damage.

Block

UV-TV reception mode

V1-VIDEO 1 INPUT MODE (AV1)

V2-VIDEO2 input mode (AV 2)

Indicated colour of mode now selected: Green and Red.

Indicated colour of other modes: White.

Green ; Normal

Red : the microcomputer operates to provide judgment of no video signal. The red color is still indicated through the signal is input

QV01: In case of indication green-normal. In case of indication red with input signal -

failure may exist in output line including QV01.

TOSHIBA – 2150 / 2876DD / 2988DG

Entering into service mode.

Press [Mute] button. Press and hold [Mute] button and press [Menu] on local keyboard.

Service mode keys

Select [PR+/-], adjust [VOL+/-],Store; [Auto], test picture [AV]

Cancellation of service standby.