BATTERY REPLACEMENT

You can use a battery pack as a source of power. The battery pack that comes with your notebook is not fully charged at the time of purchase. Follow the steps below to insert and charge the battery pack.

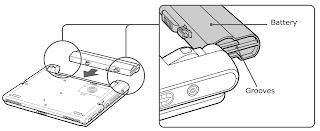

To Insert the Battery Pack

You can insert or remove the battery pack without turning off the notebook when your notebook is connected to the AC adapter. Before inserting or removing a battery pack, close the cover.

- Move the lock lever on the bottom of the notebook to the UNLOCK position.

- Align the grooves and tabs on the battery with the tabs and notches on the back of the notebook, and then slide the battery toward the notebook until it clicks into place.

INSERTING BATTERY PACK

Slide the lock lever into the LOCK position to secure the battery on the notebook.

The notebook automatically charges the battery (the battery indicator light flashes in a double-blink pattern as the battery charges). When the battery is 85% full, the battery indicator light turns off. This process takes 5.5 hours if the system is on. To charge the battery completely, continue charging for approximately 3 additional hours.

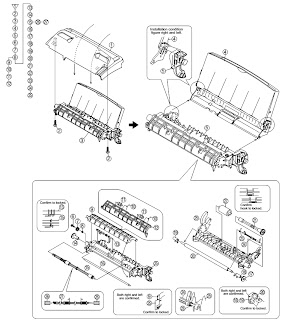

To Remove the Battery Pack

You can insert or remove the battery pack without turning off the notebook when your notebook is connected to the AC adapter. Before inserting or removing a battery pack, close the cover.

- Turn off the notebook and close the cover.

- Slide the lock lever to the UNLOCK position.

- Slide the release lever to the UNLOCK position and slide the battery away from the notebook.

You may lose data if you remove the battery pack while the notebook is on and not connected to the AC adapter or if you remove the battery while the notebook is in a power saving mode.

- If you find that an application exhibits unexpected behavior (such as reduced video quality) after returning from a power saving mode, you should close that application before your notebook enters a power saving mode.

- For maximum audio and video performance, use Power Panel to select either the AC Power Profile or the Power Management Off profile.

- If your battery level falls to less than 10 percent, you should either attach the AC adapter to recharge the battery or shut down your notebook and insert a fully charged battery.

When the internal backup battery is low on power, it may not be able to boot your system properly. You can correct this condition as follows:

- Plug in the AC adapter and allow the notebook to charge for one hour while the power is on. Do not use the notebook during this time.

- After one hour, turn the power off and then on again. To charge the internal backup battery fully, keep the AC adapter connected for more than 24 hours after turning the power on. You can use your notebook while charging the battery.

The operating system may become unstable if a lower power state such as Hibernate is initiated and then changed before the operating system completely enters the lower power state. To restore the notebook to its normal operating stability, close all open applications, and slide the power switch forward and hold it there for four seconds or more to completely shut down the notebook.