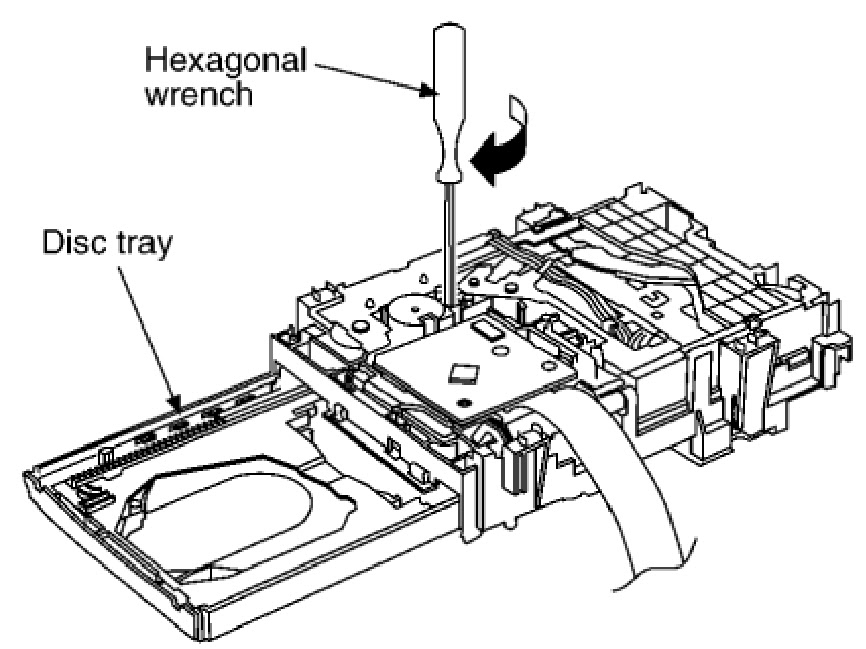

DISC REMOVAL PROCEDURE (FORCED EJECTION)

- Remove the upper case.

- Insert a clip in the hole of a drive and open a tray.

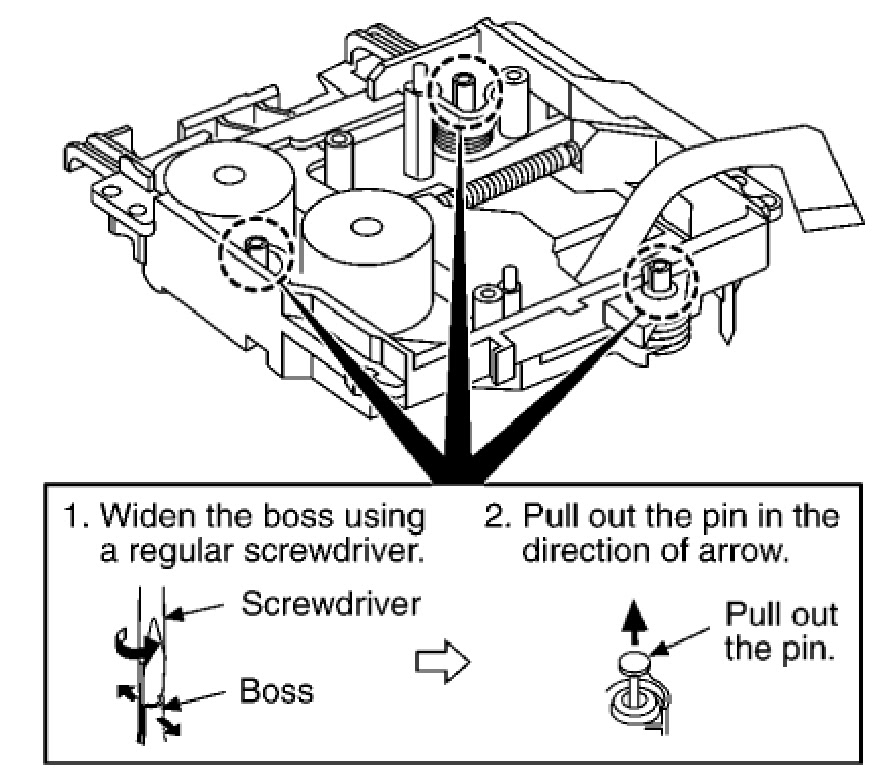

OPTICAL DEVICE REPLACEMENT

- Install it in PC after downloading two set of software.

- Microsoft .NET Framework Version 2.0 Redistributable Package (x86)

- Microsoft .NET Framework 2.0 Service Pack 1 (x86)

- Take a photograph of the bar code on the optical device. The valid bar code photo as shown.

- Drag-and-drop the bar code photograph to the icon of decode software (BDPRdec).

Because decode software cannot be attached, it separately distributes it.

- Input the password when you start decodes software.

- Write the decode data to the set.

BEFORE BU REPLACEMNT

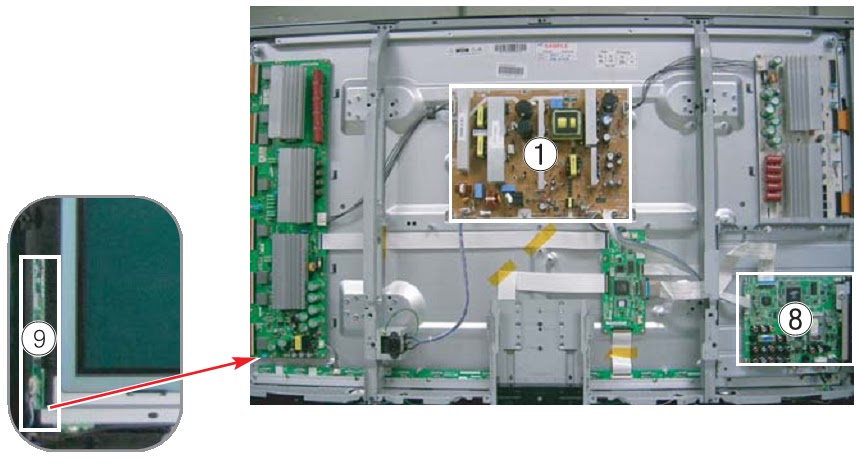

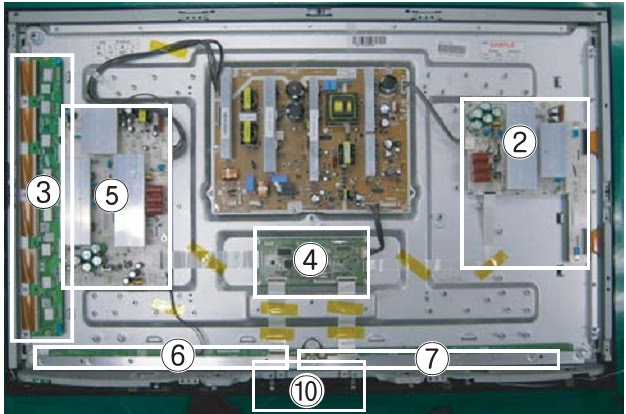

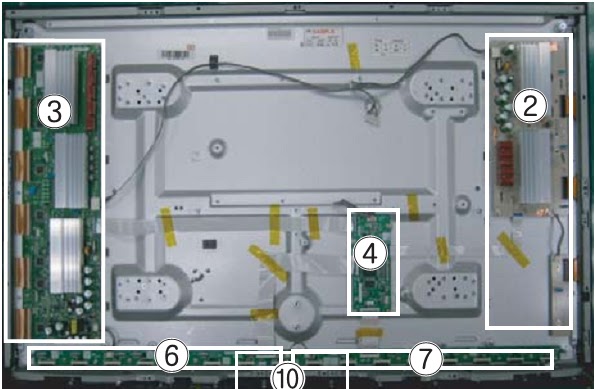

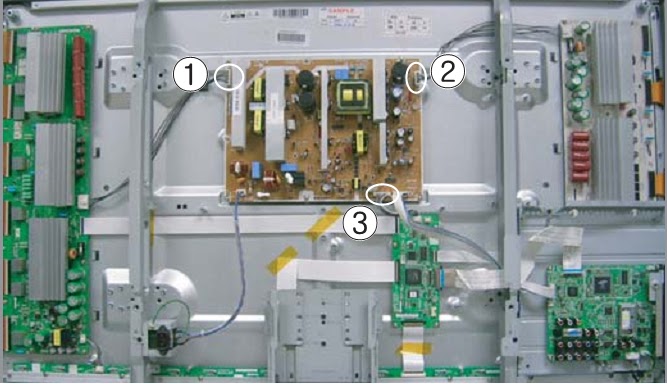

{CLICK ON PICTURES TO ZOOM}

BDP 6.9G (B D P-S1 8 5 ) series component structures as sambas conventional DVD Players. However player requires precise read out functions and also secures contents Protection system.Since above requirement, it is necessary to set/adjust BU data to EEPROM.

Replace BU(MB is original)

Replace MB (BU is original)

Replace both BU and MB

Requirement

- Digital camera (recommend with macro mode)

- Barcode decoder (BDPRdec_ver2.0) installed in JIG PC’s

- USB memory

- ESD work bench.

Do not touch any optical block parts, Turn Table and during replacing. BD Laser diode is very sensitive.

BU ADJUSTMENT FLOW

BU Data Decode Jig

JIG Name: BDPRdec. Exe

Release: 2010.11.26

Version : 2.0.0.0

Software Contents:

BDPRdec.exe ; Software

SavePath.ini ; decoded file destination setting file (initial destination is C:¥BuData.txt)

Tasman.Bars.dll ;decode dll

Uninst.exe ; unistall BDPRd ec.exe from PC

Installations

Unzip files to any PC Folder

Check the attached 2D code photo(OK_sample.JPG) drag-and-drop onto BDPRdec.exe, the Password will be required at first time only, no need P/W from second time.

If there is the error message (.NETframe work requirements) please apply Microsoft .NET Framework 2.0 (or 2.0 SP1) from Microsoft download site.