↧

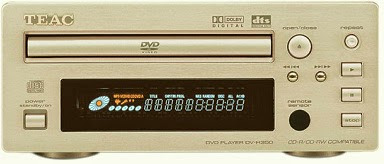

TEAC dts - DV-H550 – DV-H350 DVD PLAYER – SMPS (Power Supply) Circuit Diagrams

↧

HOW TO REPLACE A FLAT PACKAGE (SMD) IC

TO REPLACE A FLAT PACKAGE IC

* Temporary fix Flat Package IC by soldering on marked 2 pins. The most important matter is accurate setting of IC to corresponding soldering foil.

* Apply flux for all pins of Flat Package IC.

* Solder employing specified solder to direction of the arrow, as sliding the soldering iron.MODIFICATION PROCEDURE OF BRIDGE

Re-solder slightly on bridging portion.

Remove remained solder pins employing soldering iron as shown.

{Do not overheat the terminals of the IC. Do the soldering process as quick as possible & be sure a good solder points as well. A point type soldering iron bit will be the best to do this work.}

↧

↧

PANASONIC TX28XDP3L – TX25XDP3L – CTV – SERVICE MODE – SELF CHECK

TX28XDP3L – TX25XDP3L – CTV – SERVICE MODE _ Power Supply Regulator Circuit; using control IC TDA4601

SERVICE MODE* Set the bass to maximum position; set the treble to minimum position, press the Reveal button on the remote control and at the same time press the Volume Down button on the customer controls at the front panel of the TV.

* This will place the TV into the Service Mode.

* Press Red / Green buttons to step Down / Up through the functions.

* Press Yellow / Blue buttons to change the function values.

* Press the Store button on the preset panel after each adjustment has been made to store the required values.

To Exit the Service Mode, press the Normalization button.USING MEMORY PACK

SELF CHECK MODE

Self check is used to automatically check the Bus Lines and Hexadecimal code of the TV set.

To enter the self check mode, press Function Down button on the preset panel, and Status button on the remote control simultaneously.

When exiting Self Check the customer settings will return to Factory Set-up.

SELF CHECK DISPLAY

If the CCU ports have been checked and found to be incorrect ‘__’ will appear in place of ‘OK’.

Power supply regulator section circuit. TDA4601 as power control

CLICK ON THE PICTURES TO MAGNIFY

↧

HOW TO ENTER SERVICE MODE - PANASONIC TX-L32S20E - TX-LF37S20 - LCD TV

APPLICABLE TO -PANASONIC LCD TV - TX-L32S20E _ TX-L32S20L _ TX-LF32S20 _ TX-L32S20ES _ TX-L37S20E _ TX-L37S20L _ TX-LF37S20 _ TX-L37S20ES

SERVICE MODEMPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be adjusted by remote control in Service Menu.

How to enter SERVICE

* While pressing ( - / v )button on TV unit, press on the remote control for 3 times within 2 seconds.

* To exit from Service mode, press the exit button on remote control.

Key Command

* Press the 3 or 4 button to change the adjustment values or function.

* Press the 1 or 2 button to step up/down through the functions and adjustments

* Press the numerical button VOLUME ( +/- ) to change option item.

* Press the OK button after each adjustment has been made to store the required values.Service Tool Mode

To access

1 Select [SRV-TOOL] in Service Mode.

2 Press [OK] button on the remote control.

Display of SOS History

SOS History (Number of LED blinking) indication.

From left side; Last SOS, before Last, three occurrence before, 2nd occurrence after shipment, 1st occurrence after shipment.

This indication will be cleared by [Self/check indication and forced to factory shipment setting].

Power ON Time, On/Off

Note: To display TIME/COUNT menu, highlight position, then press MUTE for 3sec.

Time: Cumulative power on time, indicated hour: minute by decimal.

On/Off: Number of On/Off switching by decimal.

Note: This indication will not be cleared by either of the self-checks or any other command.

Exit

Disconnect the AC cord from wall outlet or switch off the power with [Power] button on the main unit.

CLICK ON THE PICTURES TO ZOOM IN

Hotel Mode

Purpose> To Restrict a function for hotels.

To Access command to the Hotel mode setup menu.

In order to display the Hotel mode setup menu, enter the following command (within 2 second).

[TV] : Vol.[Down] + [REMOTE] : AV(3 times)

The Hotel mode setup menu is displayed.

To exit the Hotel mode setup menu; Disconnect AC power cord from wall outlet.

The Hotel Mode Set-up Menu

↧

ACER AL1715 - LCD MONITOR - SCHEMATIC - POWER SUPPLY REGULATOR - BACK LIGHT INVERTER

↧

↧

AKAI A1211 DVD PLAYER - SMPS SCHEMATIC and TROUBLESHOOTING

SMPS (Power Supply) - Working principles.

The mains power (220V AC) fed from N1 is filtered through C1, L1, C2 and L2 then rectified by D1, D2, D3 and D4 and generates an output at 00VDC. This 300VDC fed to T1 (pin2, pin4) which connects to TEA1523P (pin2), then TEA1523Pwill automatically generate a 50 KHz square waveform, this 50 KHz square waveform controls the ON/OFF between TEA1523Ppin2 and the ground. In normal condition, T1 primary (between pin2 and pin4) will create a 50KHz square waveform which is controlled by TEA1523P , this signal then fed to T1 and generates 2 different potential voltages of 12V and 5V between pin17, pin14 and pin16, pin14 respectively . The 12VDC and 5VDC then rectified by D7, D8, and D9 and then filtered by L3, L4, L5, C9, C10 and C1 1. The feedback voltage is controlled by Ic3 TL431 and IC2 PC817. When the output voltage is higher than 5V , the voltage at TL431(2.5V) is compared with R10 and send out a signal to 5L0380R, the output square waveform then will change to adjust the output voltage, this acts as a voltage stabilizer.

SMPS PROGRAMMABLE SHUNT REGULATOR.

The TL431/TL431A are three-terminal adjustable regulator series with a guaranteed thermal stability over applicable temperature ranges. The output voltage may be set to any value between VREF (approximately 2.5 volts) and 36 volts with two external resistors. These devices have a typical dynamic

output impedance of 2.0W Active output circuitry provides a very sharp turn-on characteristic making these devices excel lent replacement for zener diodes in many applications.

POWER SUPPLY FAULT TRACING FLOW CHART

SCHEMATIC [POWER SUPPLY REGULATOR]

CLICK ON THE PICTURES TO MAGNIFY

↧

PHILIPS MAGNAVOX – 32ST220P – 27PT543 – TV – POWER SUPPLY (SMPS) SCHEMATIC

↧

ATX500T - ATX600T - SCHEMATIC - Computer Power Supply

↧

TOSHIBA SATELLITE L630 - L635 Notebook - DISASSEMBLE PROCEDURE

How to disassemble: Satellite L630 - L635 Removing the Bridge Media_ Removing the HDD_ Removing the Memory Module.

DISASSEMBLE PROCEDURE Always begin disassembly by removing the AC adapter and battery pack. Remove the optional parts and accessories as well.

To remove a pressure plate connector, pull up the tabs on either side of the connector's plastic pressure plate and gently pull the cable out of the connector. To reconnect the cable to the pressure plate's connector, raise the pressure plate up to a satisfactory height and slide the cable into the connector. Secure the cable in the correct position by pressing down the sides of the pressure plate so that the plate is flush with the sides of the connector. Grasp and pull the cable gently to check that the cable is connected firmly. If the cable comes off the connector, reinsert the cable by raising the pressure plate up to a satisfactory height.

Normal pin connectors are used for all the other types of cables. These connectors can be installed or removed by simply inserting them or pulling them out.

Removing the Battery Pack.

When handling the battery packs, use care not to short circuit the terminals. Do not drop, hit, twist, or bend the battery packs. Do not scratch or break up their casing.

* Turn the computer upside down so that the back is facing you.

* Slide out the battery lock.

* Slide the battery release latch and remove the battery pack from the computer.

Removing the Bridge Media.

Push a Bridge media. It will pop out partly when you release, so pull out the Bridge media.

Removing the Memory Module

Remove the memory module according to the following procedures, after checking that the computer is turned off in boot mode.

* Spread out the two memory lock latches so that the memory module pops up.

* Pull the memory module up and out at an angle, using care to avoid touching the connectors.

CAUTION: Do not touch the connectors on the memory modules or in the computer. Contaminated connectors can cause memory access problems.

Removing the HDD

* Release the M2.5x2.5 black flat head screw securing the HDD pack.

* Remove the HDD pack by pulling the pack, following the direction of the arrows.

Removing the ODD Bay Module.

* Turn the computer upside down.

* Remove the M2x5 white flat head screw.

* Push out on the ODD bay module in the direction of the arrow.

↧

↧

L360 - L365 - TOSHIBA NOTEBOOK – KEYBOARD – DISPLAY REMOVAL

Display Assembly_ Top Cover_ keyboard & ODD Drive Removal - L360 – L365 – TOSHIBA NOTEBOOK

Disassembling the ODD bezel.

Disassemble the ODD drive according to the following procedures.

Push out on the ODD bay module in the direction of the arrow.

Disassembling the ODD Drive.

Do not disassemble the ODD drive when it is working normally. Disassemble or replace the ODD drive only if it fails.

* Remove two M2x3 black flat head screws.

* Remove the bracket.

Removing Keyboard

Remove the Keyboard according to the following procedures.

* Release the following 11 latches on the keyboard cover, in that order:

* One latch on right side and one latch on left sides.

* Four bottom latches.

* Five front latches.

* Remove the keyboard cover.

* Remove four M2.5x2.5 black flat head screws.

* Disconnect the keyboard cable from CN250 on the system board.

* Remove the keyboard.

Removing the Wireless LAN Card

CAUTION: Do not touch the connectors on the wireless LAN card and in the computer with your bare hands. Wireless LAN cards can fail if they are contaminated with sweat, natural oils, etc. from your hands.

* Disconnect the two antenna cables with tweezers.

* Remove one M2x2 black flat head screws securing the wireless LAN card.

* Pull the wireless LAN card up from CN1300 on the system board and out at an angle.

Removing the Top Cover

* Turn the computer upside down and remove the following 18 screws:

* Twelve M2.5x6 black flat head screws.

* Four M2x2 black flat head screws.

* Turn the computer right side up.

* Disconnect the touch pad board flat cable from CN280.

* Disconnect the power board flat cable from CN201.

* Disconnect the speaker cable from CN600.

* Lift up the top cover.

Removing the Display Assembly

* Open the display panel.

* Disconnect the LCD/FL cable from CN3000 on the system board.

* Remove four M2.5x5 black flat head screws securing the LCD module to the bottom cover.

* Remove the wireless antenna cables from the bottom cover.

* Remove the display module.

↧

DESKTOP ATX POWER SUPPLY SCHEMATICS - UTIEK ATX600T - Corsair Full ATX Graphite 600T – SUNNY ATX230

↧

DELTA ATX 200 _ COMPUTER POWER SUPPLY - SCHEMATIC

↧

DURABAND DBTV1902 - SERVICE MODE - FACTORY RESET

How to enter Service Mode_Memory IC replacement & adjustments _ Default Data Values _ Factory Reset.

SERVICE MODE

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

* To enter the Service Mode, press both set key and remote control key for more than 1 second.

CONFIRMATION OF HOURS USED

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

* Set the VOLUME to minimum.

* Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 1 second.

* After the confirmation of using hours, turn off the power.

REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to ensure correct data settings while making reference to TABLE.

1. Enter DATA SET mode by setting VOLUME to minimum.

2. Press both VOL. DOWN button on the set and Channel button (6)on the remote control for more than 1 second.

3. ADDRESS and DATA should appear as FIG. ADDRESS is now selected and should "blink". Using the SET + or - keys on the remote, step through the ADDRESS until required ADDRESS to be changed is reached.

4. Press ENTER to select DATA. When DATA is selected, it will "blink".

5. Again, step through the DATA using SET + or - until required DATA value has been selected.

6. Pressing ENTER will take you back to ADDRESS for further selection if necessary.

7. Repeat steps 3 to 6 until all data has been checked.

8. When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

The unit will now have the correct DATA for the new MEMORY IC.

On-Screen Display Adjustment

* In the condition of NO indication on the screen.

8 Press the VOL. DOWN button on the set and the Channel button (9) on the remote control for more than 1 second to appear the adjustment mode on the screen as shown in Fig.

Use the Channel UP/DOWN button or Channel button (0-9) on the remote control to select the options shown in Fig.

Press the MENU button on the remote control to end the adjustments.

Confirmation of Fixed Value.

Check if the fixed values of the each adjustment items are set correctly referring below.

↧

↧

SMPS (Power Supply) - Circuit Diagram_ DURABAND DBTV 1902

↧

HOW TO ENTER SERVICE MODE - PANASONIC AG-520VDH TV/DVD/VCR Combination.

Service Mode & Display Details to AG-520VDH TV/DVD/VCR Combination.

SELF DIAGNOSISSimplified Self-Diagnostic System facilitates finding the cause of the fault. The following data will be displayed on the TV screen.

The Error Code data is stored in the Memory IC (IC6004) (latest error only). This data is cleared after it is displayed, and then the POWER button is pressed back on.

With power turned off, press FF and REW buttons on the unit together for over 3 seconds. TV power comes on and the unit goes into service mode.

The following codes will be displayed.Note: Press any operation button except for POWER or PLAY (DVD) on either the unit, or DVD key on the remote to detect that a key has been pressed.

The 3rd digit changes to “1” only when key is detected.

The 3rd digit changes to “1” only when key is detected.

USAGE SCREEN MODE

This function is displayed on the TV monitor:

The total AC plugged in AC socket (in days)

The total elapsed "Cylinder rotation" time (in hours)

The total elapsed "DVD play" time (in hours)

With power turned and no cassette, press STOP/EJECT button on VCR and 7 key on remote together.

The USAGE SCREEN will be displayed on the TV Monitor.

Notes:

1. After replacing the Cylinder Unit, press COUNTER RESET button on remote in this mode. Only Total elapsed "Cylinder rotation" time (in days) will be cleared to 0.

2. After replacing the DVD Unit, press ADD/DLT button on remote in this mode. Only Total elapsed time "DVD Play" time (in hours) will be cleared to 0.

3. To release from Usage Screen Mode, press any operation button on VCR or insert a cassette tape in this mode. VCR will return to normal operation mode.

↧

PANASONIC AG-520VDH TV/DVD/VCR Combination - SMPS SCHEMATIC

↧

DELL 2208 LCD MONITOR - SMPS AND BACK-LIGHT INVERTER SCHEMATIC

↧

↧

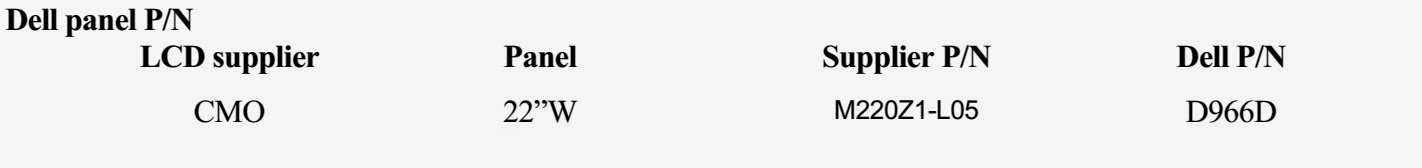

WIDESCREEN LCD MONITOR - DELL 2208WFP - SERVICE MODE - BACK-LIGHT INVERTER

Service mode entry & back-light inverter working principles _ Burn-in _ Protection mode.

SERVICE MODE [Factory Mode]With signal input, press “Power” button to turn off the monitor.

Press “Menu” and “+” buttons together, and then press “Power” button to turn on the monitor.

After power on. Press “-” key to enter Factory mode.Exit> Exit from Factory mode and back to NO OSD Status.

Auto Color> automatically calibrate chip ADC parameters by using internal DAC.

Burn In> Enable or disable the Burn-in mode by choosing ON or OFF.

Reset Timer> Reset the “Turn-on time” of the panel to 0H0M.

Color Temp> The R, G, B of Cool (9300K), Warm (5700K) and Desktop (6500K) are generated from scaling chip’s back-end white-balance program.

Time> Turn-on time of the panel.

DEBUG> Debug tool of scale IC.

Burn-in pattern

Burn-in pattern will self-generate automatically without VGA and DVI cable plugged in when the monitor set at Burn-in on mode and burn-in pattern will not be stopped until plugging in the VGA cable. Exit Burn-in mode method as follow: plugging in the VGA/DVI cable, press “Menu” button to call out OSD Main Menu, Press “Plus Key” to select “Other Settings Menu “then pop submenu and choose Factory reset.

Auto Color Balance (Automatically calibrate chip ADC parameter by using chip internal DAC.

If it is a new-built set, press “Auto/Plus” button to execute “Auto Color” at standard video pattern 5-MOSAIC pattern.

Confirm the following steps to perform “Auto Color Balance”:

* Connect the VGA cable with the standard video pattern generator and display 5-MOSAICpattern on the monitor.

* Press “Power” button to power off the monitor.

* Press “Menu” and “Auto/Plus” buttons simultaneously; then press “Power” button to power on the monitor.

* Press “Plus Key”, select “Other Settings Menu” ,then Press “Plus Key” and choose factory at bottom

* Set Burn In Mode item to ON, then execute Auto Color item.

After the “Auto Color Balance” process finished, go back to “Other Settings Menu”, and press “Factory Reset” to exit Factory mode.

Back-light Inverter _ Working Principle.

CLICK ON THE SCHEMATIC TO ZOOM IN

+5VDC provides the power for U1; the control signals Brightness and ON/OFF come from I/F board. ON/OFF signal connect to pin16 of U1 and makes U1 enable. Brightness signal connect to pin 13 of U1 and regulates the brightness of panel .TIMER makes up a network of delaying time circuit and R23 make up a divided voltage network, C3 & C18 are used to control the start-up timing. The operation frequency is determined by the external Resistor R16and capacitor C8 connected to pin3 of U1. C7 is used for soft start and compensation. The output drives, include DRV1, DRV2 (pins 6, 8,9,10 respectively) output square pulses to drive MOSFET Q6, Q7 and each of them is consist of a N+P channel MOSFET. Q6 and Q7 work as All Bridge structure, and it is high efficient, PWM switching. During start up, VSEN (pin1) senses the voltage at the transformer secondary. When VSEN reaches 3.0V, the output voltage is regulated. If no current is sensed for approximately 2seconds U1 will shut off. The current flowing through CCFLis sensed and regulated through sense resistor R6, R19. The feedback voltage connected to Pin1(ISEN),then compared with a reference voltage (1.5V) via a current amplifier, resulting that PWM drive U1 to work and output square pulses for all bridge switches.

Protection Circuit

Over-voltage and over-current protection are monitored by the voltage on VSEN (pin1). During normal operation, if a CCFL is damaged or removed, the voltage at VSEN exceeds the user-defined, preset voltage set by OVPT (pin15),the driver output duty cycle is regulated and the shutdown delay timer is

activated. OVPT sets the overall protection threshold voltage that is lower than3V (VSEN) threshold. Once the voltage at TIMER pin reaches 3V, the IC will shut down and latch. OVPT voltage setting is determined by a resistor divider (R18/R8) connected to the OVPT.

The over-voltage protection feature is implemented by using an external capacitor divider (C1/C15/C16/C17) to sense the output voltage. The divide-down voltage signal is sent to the IC Pin1 (VSEN), thus regulate the output voltage.

If a CCFL is removed, fails or is damaged during normal operation, CCFL current is no longer sensed and the voltage on ISEN pin drops. The voltage at the SSTCMP (pin2) rises rapidly because there is no current feedback at ISEN (pin14).When the voltage at SSTCMP reaches a threshold of approximately 2V and ISEN is less than 0.7V, a current source charges the capacitor (C3) connected to TIMER (pin12). Once the voltage level at the TIMER pin reaches a threshold of approximately 3V, the drive outputs shut down and latch. To resume operation, toggle the ENA signal or restart VDDA.

↧

DELL 22 inch WIDE LCD MONITOR - 2208WFP - SMPS WORKING PRINCPLE

DELL MONITOR 2208WFP _ SMPS [Power Supply] _ WORKING

AC input & EMI filter CN850 is a connector for connecting AC Power. F850 is a fuse to protect all the circuit AC. Input voltage is from 90Vto 264V. R850/3851are joined between two inputting main circuit to prevent man from shock. L850 is used to filter low frequency noise. C850and C851are used to discharge the noise that L850 produced. High frequency waves are damped by C852.

High Voltage to Low Voltage Control Circuit D850 is a rectifier in which there are 4build-in diodes, inverting AC to DC. C854 is used to smooth the wave from rectifier. U850 is a highly integrated PWM controller. Typical start-up current for U850 is only 20uA, When current flow through R8 1/R842/R843 gets to Pin 3of U850,with VDD hold-up capacitor C855, U850 is enough for starting up.

WhenU850 begins to operate Pin8of U850 will output square wave to drive Q850, then the main current flow get to GND bypassing through T850, Q850. Because of the change of current flow, wires in the other side of T850 will induct current. In the same time, the current inducted by wires which

connected T850 Pin 1 and Pin 3, with components of D852, R856 and C855 ,will be supplied to U850 for normal operating.

When the sense voltage across the sense resistor R859, reaches the threshold voltage around 0.85v, the output GATE drive will be turned off. Every time when the output of power supply is shorted or over loaded, the FB voltage will increase, the build-in PWM output will then be turned off. Both of two will prevent the power supply from being overheated under over loading condition. The PWM duty cycle is determined by this current sense signal and VFB, the feedback voltage, when the voltage on sense pin reaches V- (PWMcopm) = (Vcomp-2Vf) / 3, A switch cycle will be terminated immediately, Vcomp is internally clamped to a variable voltage around 0. 85V for output power limit.

When Q850 are turned off, the main current flow will be consumed through D851, C875, R853/R854/R855 and D853, This will prevent Q850 from being damaged under large current impulse and voltage spike.

DC_24V ,12Vand 5VOutput Circuit and Feedback circuit.

D854&D855 are used to rectify the inducted current. C862 are used to store energy when current is reversed. The parts including L852 are used to smooth the current waves that are from D854&D855, and then 24Vvoltage is supplied. D880&D881 are used to rectify the inducted current. C881 is used to store energy when current is reversed. The parts including U880 are used to change the voltage from about 13Vto steady 12V, and then 12Vvoltage is supplied. D856 is used to rectify the inducted current. C874, C864&C875are used to store energy when current is reversed. The parts including L851, and C876are used to smooth the current waves that are from D856, and then 5Vvoltage is supplied. 5Vsupply voltage feed back to PWM controller U850 via R861, R860,and I850,I851.R859,C859 and C863 are used to control response time. LD7575 implements an OVP function on Vcc .Whenever the Vcc voltage is higher than the OVP threshold voltage, the output gate drive circuit will be shutdown simultaneously thus to stop the switching of the power MOSFET until the next on.

↧

DELL E1909WDD - 19" LCD Color Monitor - SMPS and Back-light Inverter Troubleshooting

↧

.jpg)

.bmp)

.jpg)