LG 32”XGA_50”_42”_60” Plasma TelevisionsDisplay Panel Voltage (Va& Vs) adjustment procedure

50” POWER PCB Ass’y Voltage Adjustment (Va, Vs voltage Adjustment). 50PG6000, 50PG6010

Va Adjustment.

* After receiving 100% Full White Pattern, HEAT RUN.

* Connect + terminal of D. M.M. to Va pin of P811, connect -terminal to GND pin of P811.

* After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

* After receiving 100% Full White Pattern, HEAT RUN.

* Connect + terminal of D. M.M. to Va pin of P811, connect -terminal to GND pin of P811.

* After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

Vs Adjustment

* Connect + terminal of D. M..M. to Vs pin of P811, connect -terminal to GND pin of P811.

* After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

* After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

42” POWER PCB Ass’y Voltage Adjustment (Va, Vs voltage Adjustment) 42PG6000, 42PG6010

Va Adjustment.

> After receiving 100% Full White Pattern, HEAT RUN.

> Connect + terminal of D. M..M. to Va pin of P811, connect -terminal to GND pin of P811.

> After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

> Connect + terminal of D. M..M. to Va pin of P811, connect -terminal to GND pin of P811.

> After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

Vs Adjustment

> Connect + terminal of D. M..M. to Vs pin of P811, connect -terminal to GND pin of P811.

> After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

> Connect + terminal of D. M..M. to Vs pin of P811, connect -terminal to GND pin of P811.

> After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

60”(FHD), 50”(FHD) POWER PCB Ass’y Voltage Adjustment (Va, Vs voltage Adjustment). 50PG7000, 60PG7000, 50PG4000

Va Adjustment.

* After receiving 100% Full White Pattern, HEAT RUN.

* Connect + terminal of D. M..M. to Va pin of P11, connect -terminal to GND pin of P11.

* After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

* After receiving 100% Full White Pattern, HEAT RUN.

* Connect + terminal of D. M..M. to Va pin of P11, connect -terminal to GND pin of P11.

* After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

Vs Adjustment.

* Connect + terminal of D. M..M. to Vs pin of P11, connect -terminal to GND pin of P11.

* After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

* Connect + terminal of D. M..M. to Vs pin of P11, connect -terminal to GND pin of P11.

* After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

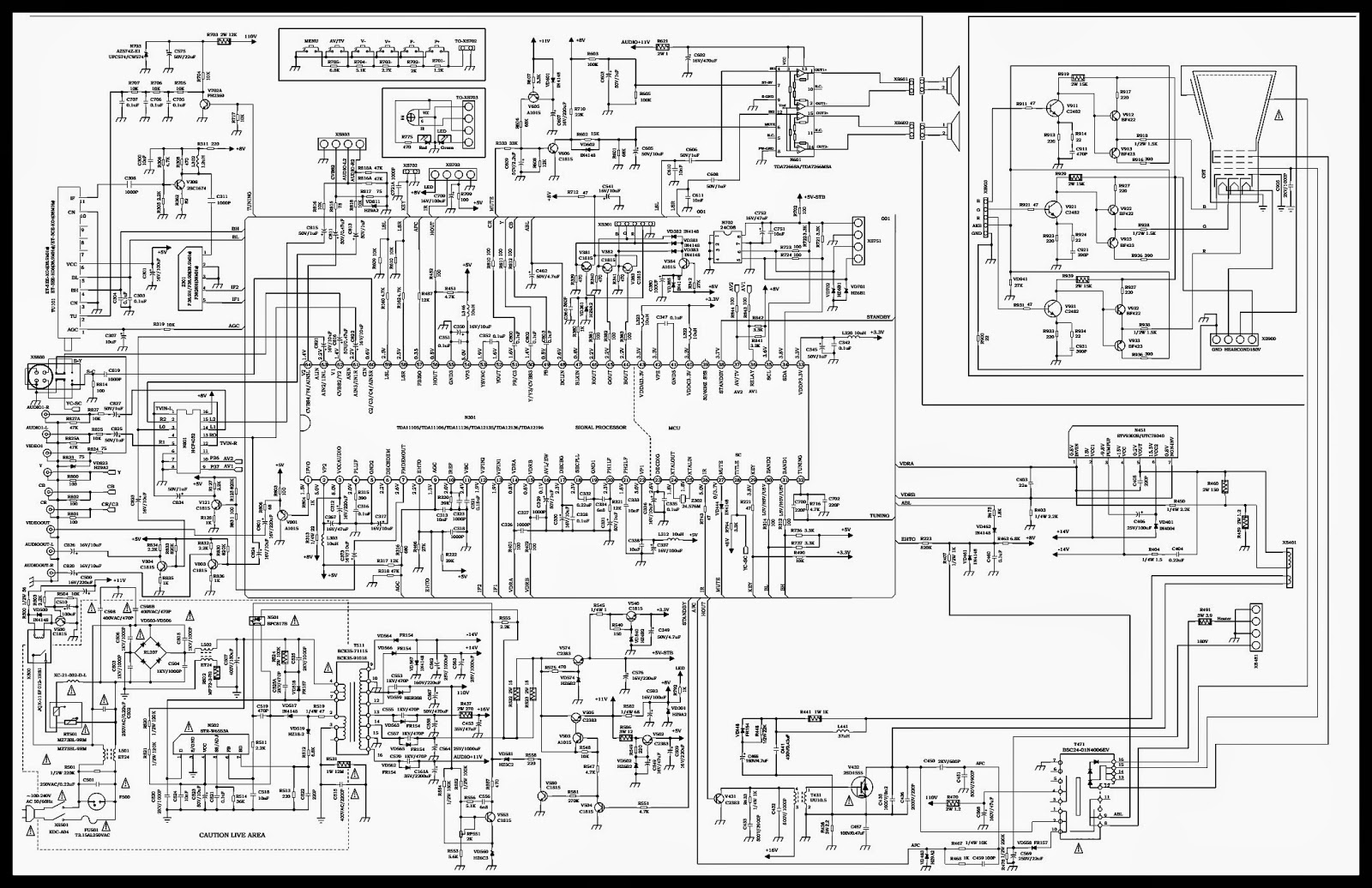

32”(XGA) POWER PCB Ass’y Voltage Adjustment (Va, Vs voltage Adjustment). 32PG6000, 32PG6010

Va Adjustment.

1. After receiving 100% Full White Pattern, HEAT RUN.

2. Connect + terminal of D. M.M. to Va pin of P811, connect -terminal to GND pin of P811.

3. After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

2. Connect + terminal of D. M.M. to Va pin of P811, connect -terminal to GND pin of P811.

3. After turning VR901,voltage of D.M.M adjustment as same as Va voltage which on label of panel right/top (deviation; ±0.5V)

Vs Adjustment

1. Connect + terminal of D. M..M. to Vs pin of P811, connect -terminal to GND pin of P811.

2. After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

2. After turning VR951, voltage of D.M.M adjustment as same as Vs voltage which on label of panel right/top(deviation ; ±0.5V)

The module keeping condition

* The normal temperature condition (more than 15°C) > Immediately the line supply.

* The module keeping condition: 0°C > The module must be kept for more than 2 hours at the normal temperature.

* The module keeping condition: -20°C > The module must be kept for more than 3 hours at the normal temperature.

* The case of Gu-mi factory at the winter season. > The module must be kept for more than 5 minutes at the heating zone (40°C~45°C)

* The module keeping condition: 0°C > The module must be kept for more than 2 hours at the normal temperature.

* The module keeping condition: -20°C > The module must be kept for more than 3 hours at the normal temperature.

* The case of Gu-mi factory at the winter season. > The module must be kept for more than 5 minutes at the heating zone (40°C~45°C)

Because this is not a hot chassis, it is not necessary to use an isolation transformer. However, the use of isolation transformer will help protect test instrument.

> Adjustment must be done in the correct order.

> The adjustment must be performed in the circumstance of 25±5°C of temperature and 65±10% of relative humidity if there is no specific designation.

> The input voltage of the receiver must keep 100~240V, 50/60Hz.

> The receiver must be operated for about 5 minutes prior to the adjustment.

After RGB Full White in HEAT-RUN Mode, the receiver must be operated prior to the adjustment.

> Adjustment must be done in the correct order.

> The adjustment must be performed in the circumstance of 25±5°C of temperature and 65±10% of relative humidity if there is no specific designation.

> The input voltage of the receiver must keep 100~240V, 50/60Hz.

> The receiver must be operated for about 5 minutes prior to the adjustment.

After RGB Full White in HEAT-RUN Mode, the receiver must be operated prior to the adjustment.

To Enter into HEAT-RUN MODE

* Press the POWER ON KEY on R/C for adjustment.

* Press the POWER ON KEY on R/C for adjustment.

* Press the ADJ KEY on R/C and enter EZ ADJUST Select “3. Test Pattern” by using D /E (CH +/-) and press ENTER(V ) Select “White” by using F /G (VOL +/-) and press ENTER(V )

> Set is activated HEAT run without signal generator in this mode.

> Single color pattern (RED / BLUE / GREEN) of HEAT RUN MODE uses to check panel.

Caution:If you turn on a still screen more than 20 minutes (Especially digital pattern, cross hatch pattern), an after image may be occur in the black level part of the screen.

> Set is activated HEAT run without signal generator in this mode.

> Single color pattern (RED / BLUE / GREEN) of HEAT RUN MODE uses to check panel.

Caution:If you turn on a still screen more than 20 minutes (Especially digital pattern, cross hatch pattern), an after image may be occur in the black level part of the screen.

.jpg)