Sanyo LED-46XR123D PAL-B/G (Australia) NTSC (AV) LED-LCD TV with 3D Function

Adjustment InstructionThe unit adjustmentAccording to the wiring diagram specified by “Product Specification”, connect power/backlight board assembly, data processing assembly, IR/Key board assembly correctly, supply with power, turn on the TV set. Check display.

Factory menu instructiona) Press key “INPUT”, then press digital keys “2, 5, 8, 0” in turn to enter into primary factory menu;

b) Press keys “▲” and “▼” to move cursor to each page of primary factory menu, then press key “OK” to enter into submenu page;

c) Press keys “▲” and “▼” to move cursor upward or downward within any one page;

d) Press keys “◄” and “►” to do adjustment when move cursor to one item;

e) Press key “MENU” to exit submenu page to the superior factory menu;

f) Press key “EXIT” to exit factory menu in any case;

g) Press key “OK” to enter the inferior factory submenu;

h) Factory menu item: Aging Mode to be used for aging the TV set; red, green blue and white full screen picture displays in turn; default setting is OFF;

i) Factory menu item: ADC ADJUST to be used for ADC calibration for VGA and Component;

j) Factory menu item: Fac. Channel Preset to be used for factory channel presetting; central signal digital frequency value for Australia program is set as CH28(529.5 MHz) and CH33(564.5 MHz); original digital program presetting could not change if central signal setting has any modification, so please search for digital program manually by perform item DTV of menu Channel;

k) Factory menu item: Color Temp. to be used for white balance adjustment;

l) Factory menu item: Store Setting Init.

m) Factory menu item: USB SW Update to be used for software updating from USB port; when U disk containing updating software is inserted into USB port, choose the item to perform updating process;

n) Factory menu item: Other Settings include settings of EEPROM Init, MEMC Update, Power mode, MST DEBUG, ISP MODE, Backlight, SSC, NONLINEAR, Video Quality, Audio Quality, Light Sensor, Overscan, etc.; no need any adjustment normally.

o) Factory menu item: Shipment to be used for initializing user data; Success flag will display after initialization, then press KEY POWER only to power off the TV set.

p) perform EEPROM Init before adjustment for the first time if software has been upgraded or data have been kept in EEPROM.

ADC calibration for D-SUB channela) Switch to D-SUB channel;

b) Press key “INPUT”, then press digital keys “2、 5、 8、 0” in turn to enter into primary factory menu;

c) Move cursor to item “ADC ADJUST” and press key “OK” to enter into the inferior submenu;

d) Input D-SUB signal (VG-849 Timing:856 (1024×768/60 Hz), Pattern:914 Chess Pattern); move cursor to item “MODE”, press keys “▲” and “▼” to choose item “RGB”, then move cursor to item “AUTO ADC” and press key “OK” to perform auto adjustment until prompt “success” displays;

ADC calibration for Component channel

a) Switch to Component channel;

b) Press key “INPUT”, then press digital keys “2、 5、 8、 0” in turn to enter into primary factory menu;

c) Move cursor to item “ADC ADJUST” and press key “OK” to enter into the inferior submenu; d) Input Component signal (VG-849 Timing:972(1080i), Pattern:918 100% color bar); move cursor to item “MODE”, press keys “▲” and “▼” to choose item “YPbPr”, then move cursor to item “AUTO ADC” and press key “OK” to perform auto adjustment until prompt “success”displays;White balance adjustment

Unless specified by customer, default settings of COOL color temperature is 12000K and chromatic coordinates is (272、278); referenced settings of Normal color temperature is 9300K and chromatic coordinates is (285、 293); referenced settings of Warm color temperature is 6500K and chromatic coordinates is (313、 329);

Default setting is Normal.Adjustment proceduresThe TV set should be working above 30 minutes to be in a stabler state before adjustment. Use CA-210 BBY channel to adjust white balance;

a) Switch to HDMI channel;

b) Press key “INPUT”, then press digital keys “2、 5、 8、 0” in turn to enter into primary factory menu;

c) Move cursor to item “W/B ADJUST” and press key “OK” to enter into the inferior submenu;

d) Input HDMI signal (VG-849 Timing:856(1024×768/60 Hz), Pattern:921 16 step Gray); move cursor to item “MODE”, press keys “▲” and “▼” to choose item “HDMI”, then move cursor to item “TEMPERTURE” and press keys “▲” and “▼” to choose “COOL”;

e) Fix “G GAIN”, adjust “R GAIN, B GAIN” to set 14th chromatic coordinates as (272、278);

f) Fix “G OFFSET”, adjust “R OFFSET、 B OFFSET” to set 4th chromatic coordinates as (272、 278);

g) To make sure chromatic coordinates of bright scale are (X=272±10,Y=278±10) and chromatic coordinates of dark scale are (X=272±10,Y=278±10) during adjusting;

h) Move cursor to item “COPY ALL” to copy white balance data to other channels except DTV channel;

i) Check if chromatic coordinates of NORMAL and WARM meet the requirements (permitted error of NORMAL bright scale: x±10, y±10, permitted error of NORMAL dark scale: x±10,y±10; permitted error of WARM bright scale and dark scale: x±10,y±10); if not, adjust “R_GAIN /B_GAIN/R_OFF/B_OFF” to be up to the requirements and then save the data;

j) Perform “Copy All” for Normal/Warm adjustments except DTV channel;

k) Check if chromatic coordinates of other channels meet the requirements, if not, do adjustment for nonstandard channel alone with the same procedures from b) to j) as HDMI channel’s and then save the data;

l) Switch to HDMI channel, change to 16-grey-scale program from central signal source, adjust white balance with the same procedures from e) to g) as HDMI channel’s; but pay attention not to perform “COPY ALL”

m) Inspect all channels after completing adjustment to check if display is normal;

n) Refer to the following rule for adjustment:

![]()

B Gain/Offset: adjust B Gain/Offset downward, coordinates of X and Y will increase, adjust B Gain/Offset upward, coordinates of X and Y will decrease;

R Gain/Offset: adjust R Gain/Offset will affect X value, but affect Lv value slightly, adjust R Gain/Offset upward, coordinates of X will increase, adjust R Gain/Offset downward, coordinates of X will decrease;

G Gain/Offset: adjust G Gain/Offset will affect Y value, and affect Lv value greatly, adjust G Gain/Offset upward, coordinates of Y will increase, adjust G Gain/Offset

downward, coordinates of Y will decrease;

Note: Sanyo customer requires that default color temperature is Normal, adjust white balance of color temperature Normal and Cool in Dynamic picture mode; for other

customers, please adjust white balance of color temperature Cool in Dynamic picture mode.

Function check

TV functions

Input central signal to RF port, enter into menu Channel first, then search for programs automatically and check if there is any omitted program; check the speakers output and the picture display;

AV port

Input AV signal with formats listed as Table 1 separately, check picture, sound and other functions;

Component port

Input Component signal from VG-849 with formats listed as Table 2 separately, check picture and sound in the case of power-on, switching channel, changing mode, etc.;

D-SUB port

Input D-SUB signal from VG-849 with formats listed as Table 3 separately, check picture and sound; if H./V. of picture displays abnormally, enter into main menu Picture->Screen->Auto Adjust to perform auto calibration.

HDMI port

HDMI port supports all signal formats supported by Component port (Table 2) and D-SUB port (Table 3), furthermore, it can also support signal with formats listed as Table 4 and Table 5 (video and audio combination). Check picture and sound in the case of power-on, switching channel, changing mode, etc;

USB port

PVR function:

Insert a formatted U disk in which recorded programs have been saved; press key “Record List” to choose and play one program, check picture, sound and other functions;

Media playing function: Insert a U disk kept files of picture, sound and video, check picture, sound and other functions;

Supported media formats as below:

Photo: JPEG, BMP, PNG

Video: H.264 , MPEG-1, MPEG-2, VC-1, FLV

Audio: WMA, MP3, M4A (AAC)

Music port(depending on different models whether contain the port or not)

Input audio signal to back VGA MUSIC/AUDIO In port from audio output equipment, check audio output is normal or not.

Other functions check

a) Check timing on/off, sleeping time off, picture/sound mode, OSD, stereo, digital audio port, etc,;

b) Check pure digital audio programs (RADIO) ;

c) Check logical channel number (LCN);

d) Check HDMI ARC;

e) Check HDMI CEC;

f) Check OAD for special customer;

User Menu Setting before Ex-factory

Enter into Factory Menu and choose “Shipment” to perform presetting before ex-factory;

Main procedures are described as follow:

a) Clear out all programs;

b) Clear out information of VCHIP, parent control, etc.;

c) Default user analog parameter setting;

d) Recover default password;

e) Set Menu Language as English;

f) Set Power mode as Standby。

Software Upgrading

Note 1 Write protection setting method: enter into ALL-100 upgrading interface “AUTO”, tick off “Config”, press “config Setting”, set option “Protect” as “All Protect” and “SRWD” as “Enable”, then press “OK” to complete write protection setting;

[make sure option “Config” is ticked off during software upgrading and reset write protection after ALL-100 upgrading software is opened each time;]

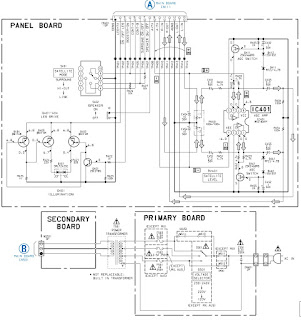

Note 2 Upgrading method with ISP upgrading instrument:

1. Main board upgrading: connect 4-core line of ISP to Debug port (X107) on main board;

The Unit upgrading: connect both VGA ports of ISP and main board, enter into factory menu and set “ISP Mode” as “ON”;

2. Use Mstar upgrading instrument (V4.4.2.0 or higher version), enter into menu “Device”, tick off “WP Pin pull to high during ISP” to make sure Flash hardware write protection is removed and erasing process is normal;

![]()

3. Press menu “Connect”, dialog box “Device Type is MX25L64” (device type depending on parts used on board actually) will display to show successful connection;

If connection is failed, press the first menu “Device” and choose “MX25L64” manually, then press “Connect”;

4. Press “Read”, choose upgrading file, such as “MERGE.bin”

5. Press “Auto”, tick off “All chip”, “program” and other necessary options;

6. Press “Run” shown as Fig. 4 to perform upgrading in two steps, “Erase” and “Program”;

Normal upgrading process:

The first step “Erasing…, Flash Status: 03” will last for some time, or erasing is failed if the step passes over immediately; please confirm procedure 2) to perform upgrading again;

The second step is “Programming…, Flash Status:00”;

Then prompt “Pass” displays;

7. Prompt “Pass” will display by button “Run” when upgrading succeeds;

8. Need not exit ISP upgrading interface if there are other TV sets to be upgraded , only procedures 3) and 6) need repeat;

Upgrading with USB

1. Make sure U disk is formatted as FAT32;

2. Copy software file named as “Merge. bin” to U disk;

3. Turn on the TV set, then insert U disk in USB port of the unit;

a) First press key “INPUT”, then press keys “2、 5、 8、 0” in turn to enter into primary factory menu;

b) Choose “USB SW Update” to begin upgrading;

4. Upgrading processes:

A. Read data from U disk while data indicator light of U disk is twinkling at the same time;

B. Upgrading flash, then the unit will be in “standby” mode;

5. Cut off the power supply and then restart the TV set, enter into factory menu to verify version and time parameter, then perform “EEPROM Init” to complete the whole upgrading processes.

Note: The USB upgrading method cannot be sure to be suitable for all kinds of U disk, so try another U disk if necessary.

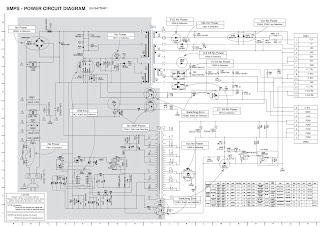

Power board (SMPS) circuit diagram

![]()

Click on the pictures to zoom in

Working Principle of the Unit

1. ATV PAL signal flow

Receive RF PAL analog signal and sent it to XC5200C (D/A silicon Tuner controlled by main chip MSD309PX through I2C bus) to be demodulated, then differential IF signal is send out to main chip MSD309PX analog demodulation to be demodulated to get analog CVBS video signal and SIF sound signal.

CVBS video signal is processed by back-end video decoder, anti-interlacing part, video processor and zoom controller, then a pair of LVDS signals are outputted to chip MST6M30 to be processed by modules of 120HZ, MEMC and 3D effect, then two pairs of LVDS signals are outputted to drive display panel.

SIF sound signal is processed by back-end demodulator to get analog sound signal, then processed by pre-amplifier, acoustic effect processor and volume controller to get two parts of signals: the analog part of signal is sent to earphone amplifier MAX9820 to be amplified and then outputted to earphone jack;

the digital part of signal I2S is sent to digital audio power amplifier TAS5711 to be processed by D/A converter and power amplifier, then outputted to drive speakers.

2. DVB-T signal flow

Receive RF DVB-T digital signal and sent it to XC5200C (D/A silicon Tuner controlled by main chip MSD309PX through I2C bus) to be processed by down-frequency-conversion, then differential IF signal is send out to main chip MSD309PX digital demodulation to be demodulated, then standard parallel transmission flow is outputted to back-end demultiplexer and decoder to be processed.

Video channel: demultiplexing digital video signal is processed by MSD309PX decoder and video processor, then a pair of LVDS signals are outputted to chip MST6M30 to be processed by modules of 120HZ, MEMC and 3D effect, then two pairs of LVDS signals are outputted to drive display panel.

Audio channel: demultiplexing digital audio signal is processed by MSD309PX decoder and audio processor, then double-sound-track analog audio signal (stereo) is outputted to MSD309PX to be processed by preamplifier, acoustic effect processor and volume controller to get two parts of signals: the analog part of signal is sent to earphone amplifier MAX9820 to be amplified and then outputted to earphone jack; the digital part of signal I2S is sent to digital audio power amplifier TAS5711 to be processed by D/A converter and power amplifier, then outputted to drive speakers.

3. AV input signal flow

AV video signal is inputted to main chip MSD309PX to be processed by video decoder, anti-interlacing part, video processor and zoom controller, then a pair of LVDS signals are outputted to chip MST6M30 to be processed by modules of 120HZ, MEMC and 3D effect, then two pairs of LVDS signals are outputted to drive display panel.

AV audio signal is processed by voltage divider, resistance matcher and AC coupler, then sent to main chip MSD309PX to be processed by acoustic effect processor and volume controller to get two parts of signals: the analog part of signal is sent to earphone power amplifier MAX9820 to be amplified and then outputted to earphone jack; the digital part of signal I2S is sent to digital audio power amplifier TAS5711 to be processed by D/A converter and power amplifier, then outputted to drive speakers.