Sony HCD-SHAKEX1/SHAKEX3/SHAKEX7 - DVD RECEIVER

AEP Model. UK Model. Australian Model ---- HCD-SHAKEX1/SHAKEX3

E Model ---- HCD-SHAKEX1/SHAKEX3/SHAKEX7

HCD-SHAKEX1 is the tuner, USB, DVD Player, Bluetooth, NFC and amplifier section in SHAKE-X1D.

HCD-SHAKEX3 is the tuner, USB, DVD Player, Bluetooth, NFC and amplifier section in SHAKE-X3D.

HCD-SHAKEX3 is the tuner, USB, DVD Player, Bluetooth, NFC and amplifier section in SHAKE-X3D.

HCD-SHAKEX7 is the tuner, USB, DVD Player, Bluetooth, NFC and amplifier section in SHAKE-X7D.

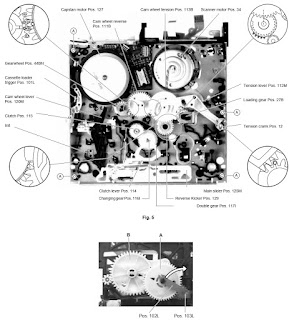

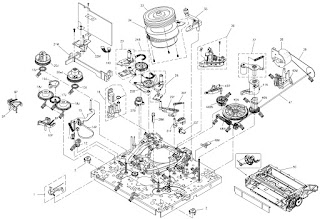

DVD Mechanism Type: CDM90-DVBU204//M

CDM90-DVBU204//M: CMS-S76RFG1 OR CMS-S76RFGP

SHAKE-X7D

Power Output (rated):: 800 W + 800 W (at 8 ohms, 100 Hz, 1% THD)

RMS output power (reference):: 1,200 W + 1,200 W (per channel at 8 ohms, 100 Hz)

Power Output (rated):: 800 W + 800 W (at 8 ohms, 100 Hz, 1% THD)

RMS output power (reference):: 1,200 W + 1,200 W (per channel at 8 ohms, 100 Hz)

SHAKE-X3D

Power Output (rated): 400 W + 400 W (at 4 ohms, 100 Hz, 1% THD)

RMS output power (reference): 600 W + 600 W (per channel at 4 ohms, 100 Hz)

Power Output (rated): 400 W + 400 W (at 4 ohms, 100 Hz, 1% THD)

RMS output power (reference): 600 W + 600 W (per channel at 4 ohms, 100 Hz)

SHAKE-X1D

Power Output (rated): 400 W + 400 W (at 4 ohms, 100 Hz, 1% THD)

RMS output power (reference): 600 W + 600 W (per channel at 4 ohms, 100 Hz)

Power Output (rated): 400 W + 400 W (at 4 ohms, 100 Hz, 1% THD)

RMS output power (reference): 600 W + 600 W (per channel at 4 ohms, 100 Hz)

* Keep the temperature of the soldering iron around 270 °C during repairing.

* Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

* Be careful not to apply force on the conductor when soldering or unsoldering.

* Do not touch the soldering iron on the same conductor of the circuit board (within 3 times).

* Be careful not to apply force on the conductor when soldering or unsoldering.

Notes on laser diode emission check

The laser beam on this model is concentrated so as to be focused on the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

The laser beam on this model is concentrated so as to be focused on the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by the charged electrostatic load, etc. on clothing and the human body.

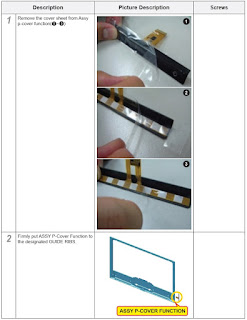

During repair, pay attention to electrostatic break-down and also use the procedure in the printed matter which is included in the repair parts. The flexible board is easily damaged and should be handled with care.

During repair, pay attention to electrostatic break-down and also use the procedure in the printed matter which is included in the repair parts. The flexible board is easily damaged and should be handled with care.

How to Pair this system with a Bluetooth device

1. Press the [Power1] button to turn the power on.2. Place the Bluetooth device within 1 meter from the system.

3. Press BLUETOOTH on the unit to select Bluetooth function. “BLUETOOTH” appears in the display panel.

4. Hold down BLUETOOTH on the unit for 2 seconds or more. “PAIRING” flashes in the display panel.

5. Perform the pairing procedure on the Bluetooth device.

6. Select the model number of the unit on the display of the Bluetooth device.( For example, select “SONY:SHAKE-X1D or SHAKE-X3D or SHAKE-X7D”.)

If passkey is required on the Bluetooth device, enter “0000”.

7. Perform the Bluetooth connection on the Bluetooth device.

8. When pairing is completed and the Bluetooth connection is established, Bluetooth device name appears in the display panel.

9. To cancel pairing operation, hold down BLUETOOTH on the unit for 2 seconds or more until “BLUETOOTH” appears in the display panel.

3. Press BLUETOOTH on the unit to select Bluetooth function. “BLUETOOTH” appears in the display panel.

4. Hold down BLUETOOTH on the unit for 2 seconds or more. “PAIRING” flashes in the display panel.

5. Perform the pairing procedure on the Bluetooth device.

6. Select the model number of the unit on the display of the Bluetooth device.( For example, select “SONY:SHAKE-X1D or SHAKE-X3D or SHAKE-X7D”.)

If passkey is required on the Bluetooth device, enter “0000”.

7. Perform the Bluetooth connection on the Bluetooth device.

8. When pairing is completed and the Bluetooth connection is established, Bluetooth device name appears in the display panel.

9. To cancel pairing operation, hold down BLUETOOTH on the unit for 2 seconds or more until “BLUETOOTH” appears in the display panel.

How to connect with a Smartphone by one touch (NFC)

Note: The operation in this mode must use a NFC-compatible Smartphone (Smartphone’s with a built-in NFC function [OS: Android 2.3.3 or later, excluding Android 3.x])

1. Press the [Power] button to turn the power on.

2. Download and install the app “NFC Easy Connect”.

Download the free Android app from Google Play by searching for “NFC Easy Connect”.

3. Start the app “NFC Easy Connect” on the Smartphone.

Make sure that the application screen is displayed.

4. Touch the Smartphone to the N-Mark on the system until the Smartphone vibrates.

1. Press the [Power] button to turn the power on.

2. Download and install the app “NFC Easy Connect”.

Download the free Android app from Google Play by searching for “NFC Easy Connect”.

3. Start the app “NFC Easy Connect” on the Smartphone.

Make sure that the application screen is displayed.

4. Touch the Smartphone to the N-Mark on the system until the Smartphone vibrates.

Complete the connection by following the instructions displayed on the Smartphone.

5. When pairing is completed and the Bluetooth connection is established, the Bluetooth device name appears in the display panel.

5. When pairing is completed and the Bluetooth connection is established, the Bluetooth device name appears in the display panel.

How to Play music from a Bluetooth device

For a Bluetooth device

1. Press the [\/1] button to turn the power on.

2. Press BLUETOOTH on the unit to select Bluetooth function. “BLUETOOTH” appears in the display panel.

3. Establish connection with the Bluetooth device. Press BLUETOOTH on the unit to connect to the last connected Bluetooth device.

Perform the Bluetooth connection from the Bluetooth device if the device is not connected.

Once the connection is established, the Bluetooth device name appears in the display panel.

1. Press the [\/1] button to turn the power on.

2. Press BLUETOOTH on the unit to select Bluetooth function. “BLUETOOTH” appears in the display panel.

3. Establish connection with the Bluetooth device. Press BLUETOOTH on the unit to connect to the last connected Bluetooth device.

Perform the Bluetooth connection from the Bluetooth device if the device is not connected.

Once the connection is established, the Bluetooth device name appears in the display panel.

Press =► Depending on the Bluetooth device,

– you may have to press =► twice.

– you may have to press =► twice.

You may need to start playback of an audio source on the Bluetooth device.

For an NFC-compatible Smartphone

Press the [Power] button to turn the power on.

Touch the Smartphone to the N-Mark on the system to establish the Bluetooth connection.

Start playback of an audio source on the Smartphone. For details on playback, refer to the operating instructions of your Smartphone.

Press the [Power] button to turn the power on.

Touch the Smartphone to the N-Mark on the system to establish the Bluetooth connection.

Start playback of an audio source on the Smartphone. For details on playback, refer to the operating instructions of your Smartphone.

To disconnect the Bluetooth device

For a Bluetooth device

Press BLUETOOTH on the unit. “BLUETOOTH” appears in the display panel.

For a Bluetooth device

Press BLUETOOTH on the unit. “BLUETOOTH” appears in the display panel.

For an NFC-compatible Smartphone

Touch the Smartphone to the N-Mark on the system again.

Touch the Smartphone to the N-Mark on the system again.

To erase all the pairing registration information perform COLD RESET test mode

Test mode

panel test mode

This mode is used to check the fluorescent indicator tube, LEDs, keys, [VOLUME/MULTI CONTROL] knob, model, destination and software version.

This mode is used to check the fluorescent indicator tube, LEDs, keys, [VOLUME/MULTI CONTROL] knob, model, destination and software version.

Procedure:

1. Press [<] button and [S3 TUNING ‒ ◄] button simultaneously and hold 3 seconds.

2. All LEDs and segments in fluorescent indicator tube are lighted up. All RGB LEDs are lighted up in white color.

3. When you want to enter to the software version display mode, press [S2 0+] button.

1. Press [<] button and [S3 TUNING ‒ ◄] button simultaneously and hold 3 seconds.

2. All LEDs and segments in fluorescent indicator tube are lighted up. All RGB LEDs are lighted up in white color.

3. When you want to enter to the software version display mode, press [S2 0+] button.

The model information appears on the fluorescent indicator tube. Press [S20+] button again to view the destination information.

4. During the destination information display, press [S2 0+] button. Each time [S2 0+] button is pressed, the fluorescent indicator tube shows the version of each category software in the following sequence: SC, MTK, OPU, UI, PF, SUB, SYS, CD, CMA, CMB, ST, TA, TM and return back to model information display.

5. When [<] button is pressed while the version numbers are being displayed except model and destination, the date of the software creation appears. When [<] button is pressed again, the display returns to the software version display.

6. Press [S1 0‒] button, the key check mode is activated.

7. In the key check mode, the fluorescent indicator tube displays “K 0 V0”.

Each time a button is pressed, “K” value increases. However, once a button has been pressed, it is no longer taken into account.

7. In the key check mode, the fluorescent indicator tube displays “K 0 V0”.

Each time a button is pressed, “K” value increases. However, once a button has been pressed, it is no longer taken into account.

“V” value increases in the manner of 0, 1, 2, 3 ... if [VOLUME/ MULTI CONTROL] knob is turned clockwise, or it decreases in the manner of 0, 9, 8, 7 ... if [VOLUME/MULTI CONTROL] knob is turned counterclockwise.

8. When [ENTER] button is pressed after all LEDs and segments in fluorescent indicator tube light up, alternate segments in fluorescent indicator tube and LEDs would light up, all RGB LEDs would light up in RED color. If you press [ENTER] button again, another half of alternate segments in fluorescent indicator tube and LEDs would light up, all RGB LEDs would light up in GREEN color. Pressing [ENTER] button again would cause all segments in fluorescent indicator tube and LEDs light up, all RGB LEDs would light up in blue color.

Pressing [ENTER] button again would turn off all segments in fluorescent indicator tube and all LEDs including RGB LEDs.

8. When [ENTER] button is pressed after all LEDs and segments in fluorescent indicator tube light up, alternate segments in fluorescent indicator tube and LEDs would light up, all RGB LEDs would light up in RED color. If you press [ENTER] button again, another half of alternate segments in fluorescent indicator tube and LEDs would light up, all RGB LEDs would light up in GREEN color. Pressing [ENTER] button again would cause all segments in fluorescent indicator tube and LEDs light up, all RGB LEDs would light up in blue color.

Pressing [ENTER] button again would turn off all segments in fluorescent indicator tube and all LEDs including RGB LEDs.

9. To release from this mode, press the buttons in the same manner as step 1, or disconnect the power cord.

User reset

The user reset clears all data including preset data stored in the data flash to initial conditions exclude history mode data.

Procedure:

1. Press the Power/1button to turn on the system.

2. Press [DJ OFF] button and [S4 TUNING +>] button simultaneously for 3 seconds.

3. “RESET” appears on the fluorescent indicator tube. After that, the fluorescent indicator tube becomes blank for a while, and the system is reset.

The user reset clears all data including preset data stored in the data flash to initial conditions exclude history mode data.

Procedure:

1. Press the Power/1button to turn on the system.

2. Press [DJ OFF] button and [S4 TUNING +>] button simultaneously for 3 seconds.

3. “RESET” appears on the fluorescent indicator tube. After that, the fluorescent indicator tube becomes blank for a while, and the system is reset.

Cold reset

The cold reset clears all data including preset data stored in the

data flash to initial conditions included history mode data. Execute

this mode when returning the set to the customer.

Procedure:

1. Press [Power1] button to turn on the system.

2. Press [<] button and [S4 TUNING +►►] button simultaneously for 3 seconds.

3. “COLD RESET” appears on the fluorescent indicator tube.

After that, the fluorescent indicator tube will display “SONY DEMO”. The set will automatically Power ON and Power OFF again, and the system is reset.

The cold reset clears all data including preset data stored in the

data flash to initial conditions included history mode data. Execute

this mode when returning the set to the customer.

Procedure:

1. Press [Power1] button to turn on the system.

2. Press [<] button and [S4 TUNING +►►] button simultaneously for 3 seconds.

3. “COLD RESET” appears on the fluorescent indicator tube.

After that, the fluorescent indicator tube will display “SONY DEMO”. The set will automatically Power ON and Power OFF again, and the system is reset.

Disc tray lock mode

This mode let you lock the disc tray. When this mode is activated, the disc tray will not open when [Eject] button is pressed. The message “LOCKED” will be displayed on the fluorescent indicator tube.

This mode only applied when there is disc on the tray.

Procedure:

1. Press [Power1] button to turn on the system.

2. Select DVD/CD function.

3. Press [DJ OFF] button and [ISOLATOR] button simultaneously and hold down until “LOCKED” or “UNLOCKED” displayed on the fluorescent indicator tube (around 5 seconds).

This mode let you lock the disc tray. When this mode is activated, the disc tray will not open when [Eject] button is pressed. The message “LOCKED” will be displayed on the fluorescent indicator tube.

This mode only applied when there is disc on the tray.

Procedure:

1. Press [Power1] button to turn on the system.

2. Select DVD/CD function.

3. Press [DJ OFF] button and [ISOLATOR] button simultaneously and hold down until “LOCKED” or “UNLOCKED” displayed on the fluorescent indicator tube (around 5 seconds).

Bluetooth pairing history clear

It can clear the Bluetooth pairing history.

Procedure:

1. Press the [Power1] button to turn the power on.

2. Press the [BLUETOOTH] button to turn the Bluetooth function.

3. Press [DJ OFF] button and [0‒] button simultaneously for 3 seconds.

4. The message “BT HISTORY” → “CLEAR” is displayed on the fluorescent indicator tube, and the pairing history of Bluetooth is cleared.

It can clear the Bluetooth pairing history.

Procedure:

1. Press the [Power1] button to turn the power on.

2. Press the [BLUETOOTH] button to turn the Bluetooth function.

3. Press [DJ OFF] button and [0‒] button simultaneously for 3 seconds.

4. The message “BT HISTORY” → “CLEAR” is displayed on the fluorescent indicator tube, and the pairing history of Bluetooth is cleared.

History mode

This mode is used to check important data stored in the system when PROTECTOR happen.

Procedure:

1. During demo mode, press [<] button and [S2 0+] button for 5 seconds to mode into history mode.

2. Press the [S4 TUNING +►►|] button or [S3 TUNING ‒ |◄◄ ] button to check history data stored.

Procedure:

1. During demo mode, press [<] button and [S2 0+] button for 5 seconds to mode into history mode.

2. Press the [S4 TUNING +►►|] button or [S3 TUNING ‒ |◄◄ ] button to check history data stored.

To release from History Mode.

To release from this mode, press [Power] button.

To release from this mode, press [Power] button.

Protect Type Description

01 =è The over current condition to MOSFET occurs by defect of MOSFET or defect of PS output line

OR

Unusual heat up of MOSFET by improper assembly of heat sink, destruction of MOSFET etc

02 =èDefect of thermistor IC or charging circuit used by SPM (Sound Pressure Management) system.

03 =èDefect of power supply circuit to AMP. There is possibility of unusual power supply of any of the AMP IC or Pre-amplifier.

04 =è DC appears in SP terminal by defect of AMP IC and MOSFET.

05 =èDefect of DC FAN and DC FAN driver circuit.

If speaker does not have output even if the set status is not in PROTECT mode, the following defect might be possible

RESET defect > Reset signal status from micom is not ‘H’

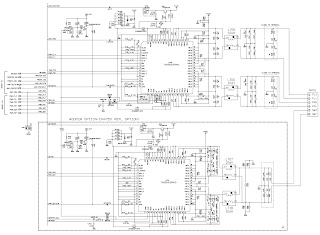

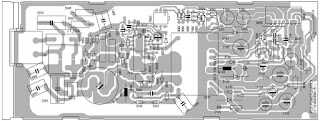

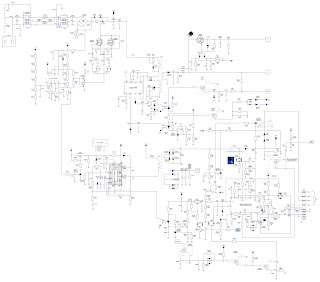

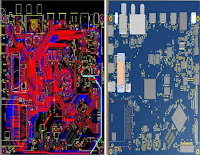

4CH D-Amp board schematic and pwb

DVD service mode

• This mode let you make diagnosis and adjustment easily by using the remote commander and the TV. The instructions, diagnostic results, etc. are given on the on-screen display.

• This mode let you make diagnosis and adjustment easily by using the remote commander and the TV. The instructions, diagnostic results, etc. are given on the on-screen display.

Test disc list

Be sure to use the DVD disc that matches the signal standards of your region.

• CD

YEDS-18 (Part No.: 3-702-101-01)

PATD-012 (Part No.: 4-225-203-01)

HLX-A1 (Part No.: J-2501-307-A)

• DVD SL (Single Layer)

NTSC : HLX-503 (Part No.: J-6090-069-A)

HLX-504 (Part No.: J-6090-088-A)

HLX-513 (Part No.: J-2501-305-A)

PAL : HLX-506 (Part No.: J-6090-077-A)

• DVD DL (Double Layer)

NTSC : HLX-501 (Part No.: J-6090-071-A)

HLX-505 (Part No.: J-6090-089-A)

HLX-514 (Part No.: J-2501-306-A)

PAL : HLX-507 (Part No.: J-6090-078-A)

Be sure to use the DVD disc that matches the signal standards of your region.

• CD

YEDS-18 (Part No.: 3-702-101-01)

PATD-012 (Part No.: 4-225-203-01)

HLX-A1 (Part No.: J-2501-307-A)

• DVD SL (Single Layer)

NTSC : HLX-503 (Part No.: J-6090-069-A)

HLX-504 (Part No.: J-6090-088-A)

HLX-513 (Part No.: J-2501-305-A)

PAL : HLX-506 (Part No.: J-6090-077-A)

• DVD DL (Double Layer)

NTSC : HLX-501 (Part No.: J-6090-071-A)

HLX-505 (Part No.: J-6090-089-A)

HLX-514 (Part No.: J-2501-306-A)

PAL : HLX-507 (Part No.: J-6090-078-A)

To enter to DVD Service Mode

Press the [Power] button to turn on the system.

2. Press [FUNCTION +] or [FUNCTION ‒] at remote commander to select DVD/CD function.

3. Press the [SPEAKER LIGHT] button and [ENTER] button simultaneously and hold 3 seconds.

4. The message “SERVICE IN” appears on the fluorescent indicator tube.

The display of the “Model Name” of the “Remocon Diagnosis Menu” change with the model and the destination appears on screen display. Refer to below on the model name.

SHAKE-X1D : TETSUJIN

SHAKE-X3D : RAIJIN

SHAKE-X7D : RYUJIN

2. Press [FUNCTION +] or [FUNCTION ‒] at remote commander to select DVD/CD function.

3. Press the [SPEAKER LIGHT] button and [ENTER] button simultaneously and hold 3 seconds.

4. The message “SERVICE IN” appears on the fluorescent indicator tube.

The display of the “Model Name” of the “Remocon Diagnosis Menu” change with the model and the destination appears on screen display. Refer to below on the model name.

SHAKE-X1D : TETSUJIN

SHAKE-X3D : RAIJIN

SHAKE-X7D : RYUJIN

5. To execute each function, press its number by using numeric button on the remote commander.

6. To release from this mode, press the [Power] button to turn off the system.

6. To release from this mode, press the [Power] button to turn off the system.

Execute IOP Measurement

In order to execute IOP measurement, the following standard procedures must be followed.

In order to execute IOP measurement, the following standard procedures must be followed.

1. From the Top Menu of Remocon Diagnosis Menu, select “2. Drive Manual Operation” by pressing the [2] button on the remote commander. The following screen appears on the onscreen display.

2. Select “3. Manual Adjustment” by pressing the [3] button on the remote commander. The following screen appears on the on-screen display.

3. Select “6. Iop:” by pressing the [6] button on the remote commander.

4. Wait until a hexadecimal number appears in the on-screen display.

4. Wait until a hexadecimal number appears in the on-screen display.

5. Convert data from hexadecimal to decimal by using conversion table.

6. Please find the label on the rear of the BU (Base Unit). The default IOP value is written in the label.

7. Subtract between these two values.

6. Please find the label on the rear of the BU (Base Unit). The default IOP value is written in the label.

7. Subtract between these two values.

8. If the remainder is smaller than 93 (decimal), then it is OK. However if the value is higher than 93, then the BU is defective and need to be change.

9. Press the [RETURN] button on the remote commander to return to previous menu.

10. Press the [0] button on the remote commander to return to the Top Menu of Remocon Diagnosis Menu.

11. Press the [Power] button to turn off the system.

9. Press the [RETURN] button on the remote commander to return to previous menu.

10. Press the [0] button on the remote commander to return to the Top Menu of Remocon Diagnosis Menu.

11. Press the [Power] button to turn off the system.

Check Emergency History

From the Top Menu of Remocon Diagnosis Menu, select “3. Emergency History” by pressing the [3] button on the remote commander.

2. You can check the total time when the laser is turned on during playback of DVD and CD from the above menu. The maximum time, which can be displayed are 999h 59min.

3. You can check the error code of latest 10 emergency history from the above menu. To view the previous or next page of emergency history, press the [|<<] button or [>>|] button on the remote commander. The error code consists of “Error

Code”, “Parameter of error code” and “Time of error code”

3. You can check the error code of latest 10 emergency history from the above menu. To view the previous or next page of emergency history, press the [|<<] button or [>>|] button on the remote commander. The error code consists of “Error

Code”, “Parameter of error code” and “Time of error code”

The meaning of error codes.

01: Communication error (No reply from syscon)

02: Syscon hung up

03: Power OFF request when syscon hung up

19: Thermal shutdown

24: MoveSledHome error

25: Mechanical move error (5 Changer)

26: Mechanical move stack error

30: DC motor adjustment error

31: DPD offset adjustment error

32: TE balance adjustment error

33: TE sensor adjustment error

34: TE loop gain adjustment error

35: FE loop gain adjustment error

36: Bad jitter after adjustment

40: Focus NG

42: Focus layer jump NG

51: Spindle stop error

52: Open kick spindle error

60: Focus on error

61: Seek fail error

62: Read Q data/ID error

70: Lead in data read fail

71: TOC read time out (CD)

80: Can’t buffering

81: Unknown media type.

01: Communication error (No reply from syscon)

02: Syscon hung up

03: Power OFF request when syscon hung up

19: Thermal shutdown

24: MoveSledHome error

25: Mechanical move error (5 Changer)

26: Mechanical move stack error

30: DC motor adjustment error

31: DPD offset adjustment error

32: TE balance adjustment error

33: TE sensor adjustment error

34: TE loop gain adjustment error

35: FE loop gain adjustment error

36: Bad jitter after adjustment

40: Focus NG

42: Focus layer jump NG

51: Spindle stop error

52: Open kick spindle error

60: Focus on error

61: Seek fail error

62: Read Q data/ID error

70: Lead in data read fail

71: TOC read time out (CD)

80: Can’t buffering

81: Unknown media type.

To clear the Laser Hours

Press the [DISPLAY] button and then press the [CLEAR] button. The data for both CD and DVD data are reset.

Press the [DISPLAY] button and then press the [CLEAR] button. The data for both CD and DVD data are reset.

To clear the Emergency History

Press the [DVD TOP MENU] button and then press the [CLEAR] button.

The error code for all emergency history would be reset.

Press the [DVD TOP MENU] button and then press the [CLEAR] button.

The error code for all emergency history would be reset.

To clear the Initialize Setup Data

Press the [DVD/TUNER MENU] button and then press the [CLEAR] button on the remote commander.

Press the [DVD/TUNER MENU] button and then press the [CLEAR] button on the remote commander.

To return to the Top Menu of Remocon Diagnosis Menu

Press the [0] button on the remote commander.

Press the [0] button on the remote commander.

To check the version information

From the Top Menu of Remocon Diagnosis Menu, select “4. Version information” by pressing the [4] button on the remote commander.

To return to the Top Menu of Remocon Diagnosis Menu, press the [0] button on the remote commander.