17MB55 Vestel Main Board have been used with several model LCD TVs. Toshiba, Panasonic, Philips and other popular brand TV manufacturers uses this kit with their several models of LCD TVs.

T/T2/C/A TUNER (U119)

The Si2158 is Silicon Labs' fourth-generation hybrid TV tuner supporting all worldwide terrestrial and cable TV standards. Requiring no external balun, SAW filters, wire wound conductors or LNAs, the Si2158 offers the lowest-cost BOM for a hybrid TV tuner. Also included are an integrated power-on reset circuit and an option for single power supply operation. As with prior-generation Silicon Labs TV tuners, the Si2158 maintains very high linearity and low noise to deliver superior picture quality and a higher number of received stations when compared to other silicon tuners and discrete MOPLL-based tuners. The Si2158 also incorporates a harmonic-rejection mixer to deliver excellent Wi-Fi and LTE immunity. For the best performance with next generation digital TV standards such as DVB-T2/C2, the Si2158 delivers industry-leading phase noise performance.

The Si2158 is Silicon Labs' fourth-generation hybrid TV tuner supporting all worldwide terrestrial and cable TV standards. Requiring no external balun, SAW filters, wire wound conductors or LNAs, the Si2158 offers the lowest-cost BOM for a hybrid TV tuner. Also included are an integrated power-on reset circuit and an option for single power supply operation. As with prior-generation Silicon Labs TV tuners, the Si2158 maintains very high linearity and low noise to deliver superior picture quality and a higher number of received stations when compared to other silicon tuners and discrete MOPLL-based tuners. The Si2158 also incorporates a harmonic-rejection mixer to deliver excellent Wi-Fi and LTE immunity. For the best performance with next generation digital TV standards such as DVB-T2/C2, the Si2158 delivers industry-leading phase noise performance.

Worldwide hybrid TV tuner

* Analog TV: NTSC, PAL/SECAM

* Digital TV: ATSC/QAM, DVBT2/T/C2/C, ISDB-T/C, DTMB

* 42-1002 MHz frequency range

· Industry-leading margin to A/74,NorDig, DTG, ARIB, EN55020,OpenCable™

· Lowest BOM for a hybrid TV tuner

* No balun at RF input

* Integrated tracking filters requiring no external conductors or SAW filters

* Increased ESD protection on 6 pins

· Best-in-class real-world reception

* Exceeds MOPLL-based tuners

* Lowest phase noise

* High Wi-Fi and LTE immunity

· Low power consumption

* 3.3 V and 1.8 V power supplies

* 3.3 V single-supply option

· Integrated power-on reset circuit

· Single or separate output pins for ALIF/DLIF connection to SoC

· Standard CMOS process

· 4 x 4 mm, 28-pin QFN package

· RoHS compliant.

* Analog TV: NTSC, PAL/SECAM

* Digital TV: ATSC/QAM, DVBT2/T/C2/C, ISDB-T/C, DTMB

* 42-1002 MHz frequency range

· Industry-leading margin to A/74,NorDig, DTG, ARIB, EN55020,OpenCable™

· Lowest BOM for a hybrid TV tuner

* No balun at RF input

* Integrated tracking filters requiring no external conductors or SAW filters

* Increased ESD protection on 6 pins

· Best-in-class real-world reception

* Exceeds MOPLL-based tuners

* Lowest phase noise

* High Wi-Fi and LTE immunity

· Low power consumption

* 3.3 V and 1.8 V power supplies

* 3.3 V single-supply option

· Integrated power-on reset circuit

· Single or separate output pins for ALIF/DLIF connection to SoC

· Standard CMOS process

· 4 x 4 mm, 28-pin QFN package

· RoHS compliant.

S/S2 TUNER (U125) OPTIONAL

The RDA5815s is a fully integrated direct conversion RF front end for DVB-S,DVB-S2&ABS-S,MMDS digital satellite Reception standard CMOS process. The receiving frequency range is from 250MHz to 2150MHz, and the baseband filter’s bandwidth can be selected from 4MHz to 40MHz with 1MHz step. The RDA5815s consists of a variable gain LNA, quadrature down converter, variable IF gain amplifiers, variable low-pass filters, reference oscillator, VCOs, synthesizer and output baseband amplifier to drive external ADC. Based on RDA’s some innovative technique, the rda5815s offers excellent phase noise and very low implementation loss, required for advanced modulation systems such as 8PSK and DVB-S2. This tuner RF IC

does not require a balun and its fully integrated design saves valuable board space and simplifies RF layout.

The RDA5815s is a fully integrated direct conversion RF front end for DVB-S,DVB-S2&ABS-S,MMDS digital satellite Reception standard CMOS process. The receiving frequency range is from 250MHz to 2150MHz, and the baseband filter’s bandwidth can be selected from 4MHz to 40MHz with 1MHz step. The RDA5815s consists of a variable gain LNA, quadrature down converter, variable IF gain amplifiers, variable low-pass filters, reference oscillator, VCOs, synthesizer and output baseband amplifier to drive external ADC. Based on RDA’s some innovative technique, the rda5815s offers excellent phase noise and very low implementation loss, required for advanced modulation systems such as 8PSK and DVB-S2. This tuner RF IC

does not require a balun and its fully integrated design saves valuable board space and simplifies RF layout.

Single-Chip RF to baseband Satellite receiver

· CMOS Fully integrated RF front end

· Low noise and wide dynamic range zero IF receiver

· Input frequency range:250 to 2150 MHz

· Input signal level: -100 to 5dBm

· More than 85dB gain control range

· Fully integrated PLL

· Integrated RX VCO

· Integrated baseband LPF with selectable cut-off frequency from 4Mhz to 40Mhz with 1Mhz step

· Integrated LNA with RF AGC

· Integrated reference oscillator

· I2C bus interface

· Automatic gain control

· 0.11um RF CMOS technology

· 3V to 3.6V operations

· Power consumption of less than 600mW

· Lower profile packages 4X4mm QFN24.

· CMOS Fully integrated RF front end

· Low noise and wide dynamic range zero IF receiver

· Input frequency range:250 to 2150 MHz

· Input signal level: -100 to 5dBm

· More than 85dB gain control range

· Fully integrated PLL

· Integrated RX VCO

· Integrated baseband LPF with selectable cut-off frequency from 4Mhz to 40Mhz with 1Mhz step

· Integrated LNA with RF AGC

· Integrated reference oscillator

· I2C bus interface

· Automatic gain control

· 0.11um RF CMOS technology

· 3V to 3.6V operations

· Power consumption of less than 600mW

· Lower profile packages 4X4mm QFN24.

T2 or S/S2 DEMODULATOR (U106) OPTIONAL

The Si216X family has 3 different IC which are pin to pin compatible. DVB-S/S2 is supported by Si2166 and DVB-T2 is supported by Si2168.

The Si216X family has 3 different IC which are pin to pin compatible. DVB-S/S2 is supported by Si2166 and DVB-T2 is supported by Si2168.

LNB SUPPLY and CONTROL IC (U108) WITH SAT OPTIONAL

Intended for analogue and digital satellite receivers/Sat-TV and Sat-PC cards, the LNBH29 series is a monolithic voltage regulator and interface IC, assembled in QFN16 (3x3) and QFN16 (4x4) specifically designed to provide the 13 / 18 V power supply and the 22 kHz tone signalling to the LNB down-converter in the antenna dish or to the multi-switch box. In this application field, it offers a complete solution with extremely low component count, low power dissipation together with a simple design and I²C standard interfacing.

This IC has a built-in DC-DC step-up converter that, from a single source from 9 V to 17.5 V, generates the voltages (VUP) that allow the linear post-regulator to work with a minimum. Dissipated power of 0.5 W typ. @ 500 mA load (the linear post-regulator drop voltage is internally kept at VUP - VOUT = 1 V typ.). The IC is also provided with an under voltage lockout circuit that disables the whole circuit when the supplied VCC drops below a fixed threshold (4.7 V typically). The step-up converter is provided with a soft-start function which reduces the inrush current during startup. The SS time is internally fixed at 4 ms type. To switch from 0 to 13 V and 6 ms typ. to switch from 0 to 18 V.

AD87587 (U124) (OPTIONAL FOR 6W and 8W PRODUCTS)Intended for analogue and digital satellite receivers/Sat-TV and Sat-PC cards, the LNBH29 series is a monolithic voltage regulator and interface IC, assembled in QFN16 (3x3) and QFN16 (4x4) specifically designed to provide the 13 / 18 V power supply and the 22 kHz tone signalling to the LNB down-converter in the antenna dish or to the multi-switch box. In this application field, it offers a complete solution with extremely low component count, low power dissipation together with a simple design and I²C standard interfacing.

This IC has a built-in DC-DC step-up converter that, from a single source from 9 V to 17.5 V, generates the voltages (VUP) that allow the linear post-regulator to work with a minimum. Dissipated power of 0.5 W typ. @ 500 mA load (the linear post-regulator drop voltage is internally kept at VUP - VOUT = 1 V typ.). The IC is also provided with an under voltage lockout circuit that disables the whole circuit when the supplied VCC drops below a fixed threshold (4.7 V typically). The step-up converter is provided with a soft-start function which reduces the inrush current during startup. The SS time is internally fixed at 4 ms type. To switch from 0 to 13 V and 6 ms typ. to switch from 0 to 18 V.

The AD87587 is an integrated audio system solution, embedding digital audio process, power stage amplifier, and a stereo 2Vrms line driver, for driving stereo bridge-tied speakers and headphone. Using I2C digital control interface, the user can control AD87587’s input format selection, mute and volume control functions. AD87587 has many built-in protection circuits to safeguard AD87587 from connection errors. It can provide 20W output power to stereo amplifiers or 40W output power for mono applications.

Features

· 16/18/20/24-bit input with I2S, Left-alignment and Right-alignment data format

· PSNR & DR(A-weighting) Loudspeaker: 97dB (PSNR), 105dB (DR) @ 24V

· Multiple sampling frequencies (Fs)

32 kHz/ 44.1 kHz / 48 kHz and

64 kHz/ 88.2 kHz / 96 kHz and

128 kHz/176.4 kHz/192 kHz

· System clock = 64x, 128x, 256x, 384x, 512x, 768x,1024x Fs

256x~1024x Fs for 32 kHz/ 44.1 kHz / 48 kHz

128x~512x Fs for 64 kHz/ 88.2 kHz / 96 kHz

64x~256x Fs for 128 kHz/176.4 kHz/192 kHz

· Supply voltage

3.3V for digital circuit

10V~26V for loudspeaker driver

· Loudspeaker output power for Stereo@ 24V

10W x 2ch into 8_ @ 0.16% THD+N

15W x 2ch into 8_ @ 0.18% THD+N

20W x 2ch into 8_ @ 0.24% THD+N

· Sounds processing including:

Volume control (+24dB~-103dB, 0.125dB/step)

Dynamic range control

Power clipping

Channel mixing

User programmed noise gate

DC-blocking high-pass filter 1

· Anti-pop design

· Short circuit and over-temperature protection

Features

· 16/18/20/24-bit input with I2S, Left-alignment and Right-alignment data format

· PSNR & DR(A-weighting) Loudspeaker: 97dB (PSNR), 105dB (DR) @ 24V

· Multiple sampling frequencies (Fs)

32 kHz/ 44.1 kHz / 48 kHz and

64 kHz/ 88.2 kHz / 96 kHz and

128 kHz/176.4 kHz/192 kHz

· System clock = 64x, 128x, 256x, 384x, 512x, 768x,1024x Fs

256x~1024x Fs for 32 kHz/ 44.1 kHz / 48 kHz

128x~512x Fs for 64 kHz/ 88.2 kHz / 96 kHz

64x~256x Fs for 128 kHz/176.4 kHz/192 kHz

· Supply voltage

3.3V for digital circuit

10V~26V for loudspeaker driver

· Loudspeaker output power for Stereo@ 24V

10W x 2ch into 8_ @ 0.16% THD+N

15W x 2ch into 8_ @ 0.18% THD+N

20W x 2ch into 8_ @ 0.24% THD+N

· Sounds processing including:

Volume control (+24dB~-103dB, 0.125dB/step)

Dynamic range control

Power clipping

Channel mixing

User programmed noise gate

DC-blocking high-pass filter 1

· Anti-pop design

· Short circuit and over-temperature protection

I2C control interface with selectable device address

· Internal PLL

· LV Under-voltage shutdown and HV Under-voltage detection

· Power saving mode

· Dynamic temperature control.

· Internal PLL

· LV Under-voltage shutdown and HV Under-voltage detection

· Power saving mode

· Dynamic temperature control.

DRV632 (U121) (OPTIONAL HP DRIVER FOR 2.5W PRODUCTS)

The DRV632 is a 2-VRMS pop-free stereo line driver designed to allow the removal of the output dcblocking capacitors for reduced component count and cost. The device is ideal for single-supply electronics where size and cost are critical design parameters. The DRV632 is capable of driving 2 VRMS into a 10-kΩ load with 3.3-V supply voltage. The device has differential inputs and uses external gain-setting resistors to support a gain range of ±1 V/V to ±10 V/V, and gain can be configured individually for each channel. The DRV632 has built-in active-mute control for pop-free audio on/off control. The DRV632 has an external under voltage detector that mutes the output when the power supply is removed, ensuring a pop-free shutdown.

The DRV632 does not require a power supply greater than 3.3 V to generate its 5.6-Vpp output, nor does it require a split-rail power supply. The DRV632 integrates its own charge pump to generate a negative supply rail that provides a clean, pop-free ground-biased 2-VRMS output. The DRV632 is available in a 14-pin TSSOP.

POWER STAGEThe DRV632 is a 2-VRMS pop-free stereo line driver designed to allow the removal of the output dcblocking capacitors for reduced component count and cost. The device is ideal for single-supply electronics where size and cost are critical design parameters. The DRV632 is capable of driving 2 VRMS into a 10-kΩ load with 3.3-V supply voltage. The device has differential inputs and uses external gain-setting resistors to support a gain range of ±1 V/V to ±10 V/V, and gain can be configured individually for each channel. The DRV632 has built-in active-mute control for pop-free audio on/off control. The DRV632 has an external under voltage detector that mutes the output when the power supply is removed, ensuring a pop-free shutdown.

The DRV632 does not require a power supply greater than 3.3 V to generate its 5.6-Vpp output, nor does it require a split-rail power supply. The DRV632 integrates its own charge pump to generate a negative supply rail that provides a clean, pop-free ground-biased 2-VRMS output. The DRV632 is available in a 14-pin TSSOP.

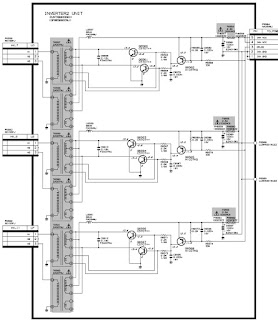

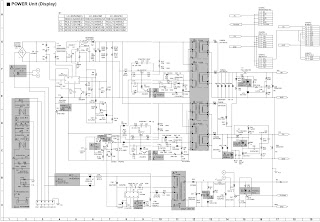

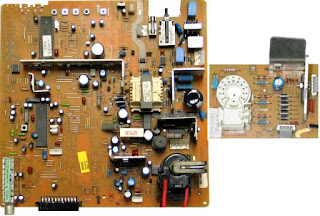

The DC voltages required for different blocks of the main board and panel are provided by main power supply unit. MB55 chassis can operate with PW05, IPS60, IPS61, IPS70, IPS20, IPS11, IPS16, IPS17, IPS19, PW25, PW26, PW03, PW04, PW06, and PW07 as main power supply and also with 12V adaptor. The main difference from previous projects MB55 uses the 2x6 pin power connector. And only 12V_STBY supply is necessary to provide all required board supplies. As the main power board has 2x6 pin option, MB55 can operate with above given power boards.

Which power board can be used for board to board or cable connection?

Board to board (BTB): PW05, IPS60, IPS61, IPS70, IPS11, IPS16, IPS17, IPS19

Board to board (BTB): PW05, IPS60, IPS61, IPS70, IPS11, IPS16, IPS17, IPS19

Power Cable: PW25, PW26, PW03, PW04, PW06, PW07, IPS20,

The power supplies generate 12V standby mode DC voltage and 24V system voltage only for audio IC voltage in necessary situations. Power stage which is on-chassis generates 5V, 3V3 stand by voltage and 12V, 5V, 3V3, 2.5V, 1.5V, 1.2 and 1.15V supplies for other blocks of the chassis. The power block diagram with the blocks power requirements of MB55 is given below. And also you can find below the details about the Step down IC’s and LDO’s which are used in MB55 main board.

The power supplies generate 12V standby mode DC voltage and 24V system voltage only for audio IC voltage in necessary situations. Power stage which is on-chassis generates 5V, 3V3 stand by voltage and 12V, 5V, 3V3, 2.5V, 1.5V, 1.2 and 1.15V supplies for other blocks of the chassis. The power block diagram with the blocks power requirements of MB55 is given below. And also you can find below the details about the Step down IC’s and LDO’s which are used in MB55 main board.

RT7278 (U101) (3A) – RT7240 (U101) (5A)

The RT7278/RT7240 is a synchronous step down converter with Advanced Constant On-Time (ACOT) mode control. The ACOT provides a very fast transient response with few external components. The low impedance internal MOSFET supports high efficiency operation with wide input voltage range from 4.5V to 17V. The proprietary circuit of the RT7278/RT7240 enables to support all ceramic capacitors. The output voltage can be adjustable between 0.8V and 8V. The soft-start is adjustable by an external capacitor.

Features

· ACOT Mode Enables Fast Transient Response

· 4.5V to 17V Input Voltage Range

· 3A Output Current

· 60mOhm Internal Low Site N-MOSFET

· Advanced Constant On-Time Control

· Support All Ceramic Capacitors

· Up to 95% Efficiency

The RT7278/RT7240 is a synchronous step down converter with Advanced Constant On-Time (ACOT) mode control. The ACOT provides a very fast transient response with few external components. The low impedance internal MOSFET supports high efficiency operation with wide input voltage range from 4.5V to 17V. The proprietary circuit of the RT7278/RT7240 enables to support all ceramic capacitors. The output voltage can be adjustable between 0.8V and 8V. The soft-start is adjustable by an external capacitor.

Features

· ACOT Mode Enables Fast Transient Response

· 4.5V to 17V Input Voltage Range

· 3A Output Current

· 60mOhm Internal Low Site N-MOSFET

· Advanced Constant On-Time Control

· Support All Ceramic Capacitors

· Up to 95% Efficiency

· 700kHz Switching Frequency

· Adjustable Output Voltage from 0.8V to 8V

· Adjustable Soft-Start

· Cycle-by-Cycle Current Limit

· Input Under Voltage Lockout

· Thermal Shutdown Protection.

· Adjustable Output Voltage from 0.8V to 8V

· Adjustable Soft-Start

· Cycle-by-Cycle Current Limit

· Input Under Voltage Lockout

· Thermal Shutdown Protection.

MP1498 (U103 & U104) (2A)

The MP1498 is a high-frequency, synchronous, rectified, step-down, switch-mode converter with built-in internal power MOSFETs. It offers a very compact solution to achieve 2A continuous output current with excellent load and line regulation over a wide input supply range. The MP1498 has synchronous mode operation for higher efficiency over the output current load range. Current-mode operation provides a fast transient response and eases loop stabilization. Protective features include over-current protection, thermal shutdown, and external SS control.

The MP1498 is a high-frequency, synchronous, rectified, step-down, switch-mode converter with built-in internal power MOSFETs. It offers a very compact solution to achieve 2A continuous output current with excellent load and line regulation over a wide input supply range. The MP1498 has synchronous mode operation for higher efficiency over the output current load range. Current-mode operation provides a fast transient response and eases loop stabilization. Protective features include over-current protection, thermal shutdown, and external SS control.

· Wide 4.5V-to-16V Operating Input Range

· 100mΩ/40mΩ Low RDS(ON) Internal Power MOSFETs

· Proprietary Switching-Loss–Reduction Technique

· High-Efficiency Synchronous Mode Operation

· Fixed 1.4MHz Switching Frequency

· Can Synchronize to a 300kHz-to-3MHz External Clock

· Externally-Programmable Soft-Start

· OCP and Hiccup

· Thermal Shutdown

· Output Adjustable from 0.8V

· Available in an 8-pin TSOT-23 Package.

· 100mΩ/40mΩ Low RDS(ON) Internal Power MOSFETs

· Proprietary Switching-Loss–Reduction Technique

· High-Efficiency Synchronous Mode Operation

· Fixed 1.4MHz Switching Frequency

· Can Synchronize to a 300kHz-to-3MHz External Clock

· Externally-Programmable Soft-Start

· OCP and Hiccup

· Thermal Shutdown

· Output Adjustable from 0.8V

· Available in an 8-pin TSOT-23 Package.

TLV70033 (U107)

The TLV700xx series of low-dropout (LDO) linear regulators are low quiescent current devices with excellent line and load transient performance. These LDOs are designed for power-sensitive applications. A precision band gap and error amplifier provides overall 2% accuracy. Low output noise, very high power supply rejection ratio (PSRR), and low dropout voltage make this series of devices ideal for most battery operated handheld equipment. All device versions have thermal shutdown and current limit for safety.

Features

· 23Very Low Dropout:

43 mV at IOUT = 50 mA, VOUT = 2.8 V

85 mV at IOUT = 100 mA, VOUT = 2.8 V

175 mV at IOUT = 200 mA, VOUT = 2.35 V

· 2% Accuracy

· Low IQ: 31 μA

· Available in Fixed-Output Voltages from 1.2 V to 4.8 V

· High PSRR: 68 dB at 1 kHz.

The TLV700xx series of low-dropout (LDO) linear regulators are low quiescent current devices with excellent line and load transient performance. These LDOs are designed for power-sensitive applications. A precision band gap and error amplifier provides overall 2% accuracy. Low output noise, very high power supply rejection ratio (PSRR), and low dropout voltage make this series of devices ideal for most battery operated handheld equipment. All device versions have thermal shutdown and current limit for safety.

Features

· 23Very Low Dropout:

43 mV at IOUT = 50 mA, VOUT = 2.8 V

85 mV at IOUT = 100 mA, VOUT = 2.8 V

175 mV at IOUT = 200 mA, VOUT = 2.35 V

· 2% Accuracy

· Low IQ: 31 μA

· Available in Fixed-Output Voltages from 1.2 V to 4.8 V

· High PSRR: 68 dB at 1 kHz.

TLV1117LV15 (U111)

The TLV1117LV series of low-dropout (LDO) linear regulators is a low input voltage version of the popular 1117 voltage regulator. The TLV1117LV is an extremely low-power device that consumes 500 times lower quiescent current than traditional 1117 voltage regulators, making it suitable for applications that mandate very low standby current. The TLV1117LV family of LDOs is also stable with 0 mA of load current; there is no minimum load requirement, making it an ideal choice for applications where the regulator is required to power very small loads during standby in addition to large currents on the order of 1 A during normal operation. The TLV1117LV offers excellent line and load transient performance, resulting in very small magnitude undershoots and overshoots of output voltage when the load current requirement changes from less than 1 mA to more than 500 mA.

Features

· 1.5% Typical Accuracy

· Low IQ: 100 μA (max)

· 500 times lower than standard 1117 devices

· VIN: 2.0 V to 5.5 V

· Absolute maximum VIN = 6.0 V

· Stable with 0-mA Output Current

· Low Dropout: 455 mV at 1 A for VOUT = 3.3 V

· High PSRR: 65 dB at 1 kHz

· Minimum Ensured Current Limit: 1.1 A

· Stable with Cost-Effective Ceramic Capacitors:

· With 0-Ω ESR

· Thermal Shutdown and Over current Protection.

The TLV1117LV series of low-dropout (LDO) linear regulators is a low input voltage version of the popular 1117 voltage regulator. The TLV1117LV is an extremely low-power device that consumes 500 times lower quiescent current than traditional 1117 voltage regulators, making it suitable for applications that mandate very low standby current. The TLV1117LV family of LDOs is also stable with 0 mA of load current; there is no minimum load requirement, making it an ideal choice for applications where the regulator is required to power very small loads during standby in addition to large currents on the order of 1 A during normal operation. The TLV1117LV offers excellent line and load transient performance, resulting in very small magnitude undershoots and overshoots of output voltage when the load current requirement changes from less than 1 mA to more than 500 mA.

Features

· 1.5% Typical Accuracy

· Low IQ: 100 μA (max)

· 500 times lower than standard 1117 devices

· VIN: 2.0 V to 5.5 V

· Absolute maximum VIN = 6.0 V

· Stable with 0-mA Output Current

· Low Dropout: 455 mV at 1 A for VOUT = 3.3 V

· High PSRR: 65 dB at 1 kHz

· Minimum Ensured Current Limit: 1.1 A

· Stable with Cost-Effective Ceramic Capacitors:

· With 0-Ω ESR

· Thermal Shutdown and Over current Protection.

SHORT CIRCUIT PROTECTION CIRCUIT

Short circuit protection is necessary for protecting chassis and main IC against damages when any Vcc supply shorts to ground. Protect pin should be logic high while normal operation. When there is a short circuit protect pin should be logic low. After any short detection, SW forces the system to go into standby mode and to indicate short circuit detection LEDs on LED card blinked in a determined sequence.

Short circuit protection is necessary for protecting chassis and main IC against damages when any Vcc supply shorts to ground. Protect pin should be logic high while normal operation. When there is a short circuit protect pin should be logic low. After any short detection, SW forces the system to go into standby mode and to indicate short circuit detection LEDs on LED card blinked in a determined sequence.

MICROCONTROLLER – Novatek: NT72567 (MAIN IC) (U112)

The NT72567 is an integrated digital TV system-on-chip which compliants with variety ATV as NTSC, PAL and SECAM, and DTV standards as ISDB-T, DVB-T/-C, ITU-T J.83B, integrates DTV and multi-media AV decoder, SIF demodulator, and support A/V post-processing. The integrated video ADC and video decoder support PC VGA port, YPbPr, SCART, CVBS and S-Video Input. Regarding the tuner input, The digital VIF performs the universal analogue TV demodulation (NTSC, PAL, and SECAM), including IF processing, AGC, video demodulation, and second sound IF generation (SSIF). The video decoder supports universal TV video format. The integrated audio ADC supports stereo audio input corresponding to video input sources. The integrated TV sound decoder supports universal TV sound format. The advanced picture quality and color engine create more vivid image impression than ever. The HDMI receiver v1.4a supports deep color, CEC features and 3D formats. The USB high speed host supports updating

firmware code, multi-media playback from the external USB flash devices. The standby controller can operate solely from the main system, powered by the standby power source from power module, consumes as low current as possible. It meets the requirement of Green appliance.

The NT72567 is an integrated digital TV system-on-chip which compliants with variety ATV as NTSC, PAL and SECAM, and DTV standards as ISDB-T, DVB-T/-C, ITU-T J.83B, integrates DTV and multi-media AV decoder, SIF demodulator, and support A/V post-processing. The integrated video ADC and video decoder support PC VGA port, YPbPr, SCART, CVBS and S-Video Input. Regarding the tuner input, The digital VIF performs the universal analogue TV demodulation (NTSC, PAL, and SECAM), including IF processing, AGC, video demodulation, and second sound IF generation (SSIF). The video decoder supports universal TV video format. The integrated audio ADC supports stereo audio input corresponding to video input sources. The integrated TV sound decoder supports universal TV sound format. The advanced picture quality and color engine create more vivid image impression than ever. The HDMI receiver v1.4a supports deep color, CEC features and 3D formats. The USB high speed host supports updating

firmware code, multi-media playback from the external USB flash devices. The standby controller can operate solely from the main system, powered by the standby power source from power module, consumes as low current as possible. It meets the requirement of Green appliance.

DDR3 SDRAM K4B1G1646G 1GB G-DIE (U113)

The 1 GB DDR3 SDRAM G-die is organized as a 8Mbit x 16 I/Os x 8banks device. This synchronous device achieves high speed double-data-rate transfer rates of up to 2133Mb/sec/pin (DDR3-2133) for general applications. The chip is designed to comply with the following key DDR3 SDRAM features such as posted CAS, Programmable CWL, Internal (Self) Calibration, On Die Termination using ODT pin and Asynchronous Reset . All of the control and address inputs are synchronized with a pair of externally supplied differential clocks. Inputs are latched at the cross point of differential clocks (CK rising and CK falling). All I/Os are synchronized with a pair of bidirectional strobes (DQS and DQS) in a source synchronous fashion. The address bus is used to convey row, column, and bank address information in a RAS/CAS multiplexing style. The DDR3 device operates with a single 1.5V ± 0.075V power supply and 1.5V ± 0.075V VDDQ. The 1 GB DDR3 G-die device is available in 96ball FBGA(x16).

The 1 GB DDR3 SDRAM G-die is organized as a 8Mbit x 16 I/Os x 8banks device. This synchronous device achieves high speed double-data-rate transfer rates of up to 2133Mb/sec/pin (DDR3-2133) for general applications. The chip is designed to comply with the following key DDR3 SDRAM features such as posted CAS, Programmable CWL, Internal (Self) Calibration, On Die Termination using ODT pin and Asynchronous Reset . All of the control and address inputs are synchronized with a pair of externally supplied differential clocks. Inputs are latched at the cross point of differential clocks (CK rising and CK falling). All I/Os are synchronized with a pair of bidirectional strobes (DQS and DQS) in a source synchronous fashion. The address bus is used to convey row, column, and bank address information in a RAS/CAS multiplexing style. The DDR3 device operates with a single 1.5V ± 0.075V power supply and 1.5V ± 0.075V VDDQ. The 1 GB DDR3 G-die device is available in 96ball FBGA(x16).

PANEL SUPPLY SWITCH CIRCUIT

This switch is used to open and close panel supply of TCON. It is controlled by port of main µcontroller. Also, with this circuit, the panel power sequences could be adjusted correctly. 2 panel supply options are connected to the circuit. All of them are optional according to panels.

This switch is used to open and close panel supply of TCON. It is controlled by port of main µcontroller. Also, with this circuit, the panel power sequences could be adjusted correctly. 2 panel supply options are connected to the circuit. All of them are optional according to panels.

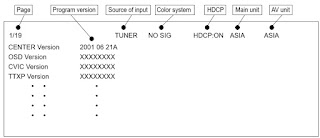

SERVICE MENU SETTINGS

In order to reach the service menu, first press “MENU” button, then press “4725” from the remote controller keypad.

In order to reach the service menu, first press “MENU” button, then press “4725” from the remote controller keypad.

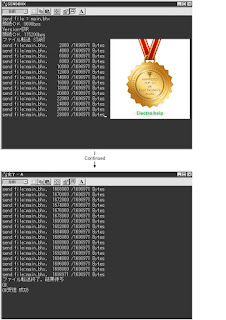

SOFTWARE UPDATE

Software update procedure can be done by following these steps below:

1. The format of the USB stick, which will be used in software update, should be in FAT32.

2. “bornova_usb_update.bin” and “bornova_usb_update.scr” files should be copied in the root directory.

3. Plug in USB stick to the TV when it is powered off.

4. Press and hold the “OK” button in the remote controller while the TV is turned off then turn on the TV.

When IR LED starts to blink, release the “OK” button and wait for installation. It may take several minutes.

Software update procedure can be done by following these steps below:

1. The format of the USB stick, which will be used in software update, should be in FAT32.

2. “bornova_usb_update.bin” and “bornova_usb_update.scr” files should be copied in the root directory.

3. Plug in USB stick to the TV when it is powered off.

4. Press and hold the “OK” button in the remote controller while the TV is turned off then turn on the TV.

When IR LED starts to blink, release the “OK” button and wait for installation. It may take several minutes.

This procedure finishes successfully with First Time Installation screen and then required selections will be done.

NO BACK-LIGHT PROBLEM

Problem: TV is working, IR led is OFF but there is no picture and back-light on the panel.

Possible causes: BACK-LIGHT_ON/OFF pin, DIMMING pin, back-light supply, STBY ON/OFF pin Solution: BACK-LIGHT_ON/OFF pin should be high in back-light open position. If it is low, check Q100 and panel cables.

Problem: TV is working, IR led is OFF but there is no picture and back-light on the panel.

Possible causes: BACK-LIGHT_ON/OFF pin, DIMMING pin, back-light supply, STBY ON/OFF pin Solution: BACK-LIGHT_ON/OFF pin should be high in back-light open position. If it is low, check Q100 and panel cables.

DIMMING pin should be high or square wave in back-light open position. If it is low, please check S128 for Novatek side and panel or power cables, connectors.

For W/ADAPTOR models, back-light power supply should be in panel specs. Please check CN102 and related connectors for power supply cards.

STBY_ON/OFF should be low for standby on condition, check R104.

CI MODULE PROBLEM

Problem: CI is not working when CI module inserted.

Possible causes: Supply, supply control pin, detect pins, mechanical positions (short circuit) of pins.

Problem: CI is not working when CI module inserted.

Possible causes: Supply, supply control pin, detect pins, mechanical positions (short circuit) of pins.

Solution: CI supply should be 5V when CI module inserted. If it is not 5V check CI_POWER_CTRL, this pin should be low.

Check mechanical positions of CI module in case a short circuit.

Detect ports should be low. If it is not low, please check CI connector pins, CI module pins and VCC_PCMCIA.

Detect ports should be low. If it is not low, please check CI connector pins, CI module pins and VCC_PCMCIA.

LED BLINKING PROBLEM

Problem: LED blinking, no other operation

Possible causes: A short circuit on Vcc voltages.

Solution: Protect pin should be logic high while the TV is in normal operation. When there is a short circuit, protect pin will be logic low. If you detect logic low on protect pin, unplug the TV set and control voltage points with a multimeter to find the shorted voltage to ground.

Problem: LED blinking, no other operation

Possible causes: A short circuit on Vcc voltages.

Solution: Protect pin should be logic high while the TV is in normal operation. When there is a short circuit, protect pin will be logic low. If you detect logic low on protect pin, unplug the TV set and control voltage points with a multimeter to find the shorted voltage to ground.

IR PROBLEM

Problem: IR or LED is not working.

Possible causes: No supply on the LED card.

Solution: Please check LED card supply.

Problem: IR or LED is not working.

Possible causes: No supply on the LED card.

Solution: Please check LED card supply.

KEYPAD OR TOUCH-PAD PROBLEM

Problem: Keypad or Touch-pad is not working.

Possible causes: No supply on the Keypad card.

Solution: Please check Keypad supply and KEYBOARD pin.

Problem: Keypad or Touch-pad is not working.

Possible causes: No supply on the Keypad card.

Solution: Please check Keypad supply and KEYBOARD pin.

USB PROBLEMS

Problem: USB is not working or no USB Detection.

Possible causes: No supply on the USB Interface circuit.

Solution: check USB Supply, it should be nearly 5V.

Problem: USB is not working or no USB Detection.

Possible causes: No supply on the USB Interface circuit.

Solution: check USB Supply, it should be nearly 5V.

NO SOUND PROBLEM AT MAIN SPEAKERS

Problem: No audio at main speaker outputs.

Possible causes: No supply voltages on VDD_AUDIO, 5V_VCC, 3V3_VCC, 12V_VCC or VDD_AUDIO_PWR.

Problem: No audio at main speaker outputs.

Possible causes: No supply voltages on VDD_AUDIO, 5V_VCC, 3V3_VCC, 12V_VCC or VDD_AUDIO_PWR.

A problem in headphone connector or headphone detect circuit.

Solution: Please check supply voltages of VDD_AUDIO, 5V_VCC, 3V3_VCC, 12V_VCC and VDD_AUDIO_PWR with a voltage-meter. Check headphone connector and headphone detect circuit (when headphone is connected, speakers are automatically muted). Measure voltage at HP_DETECT pin, it should be 3.3v.

Solution: Please check supply voltages of VDD_AUDIO, 5V_VCC, 3V3_VCC, 12V_VCC and VDD_AUDIO_PWR with a voltage-meter. Check headphone connector and headphone detect circuit (when headphone is connected, speakers are automatically muted). Measure voltage at HP_DETECT pin, it should be 3.3v.

NO SOUND PROBLEM AT HEADPHONE

Problem: No audio at headphone output.

Possible causes: No supply voltages on 5V_VCC, 3V3_VCC or a problem in headphone connector or headphone detect pin.

Solution: Please check supply voltages of 5V_VCC, 3V3_VCC with a voltage-meter. Please check headphone connector and headphone detect pin when the headphone is plugged in. Measure voltage at HP_DETECT pin, it should be low state (0V). A headphone sign should be seen in OSD screen when volume up or down button is pressed in the remote controller.

Problem: No audio at headphone output.

Possible causes: No supply voltages on 5V_VCC, 3V3_VCC or a problem in headphone connector or headphone detect pin.

Solution: Please check supply voltages of 5V_VCC, 3V3_VCC with a voltage-meter. Please check headphone connector and headphone detect pin when the headphone is plugged in. Measure voltage at HP_DETECT pin, it should be low state (0V). A headphone sign should be seen in OSD screen when volume up or down button is pressed in the remote controller.

STANDBY ON/OFF PROBLEM

Problem: Device cannot boot, TV hangs in standby mode.

Possible causes: No power supply or a problem about software.

Solution: Please check 12V_VCC, 5V_VCC and 3V3_VCC with a voltage-meter. Try to update TV with latest SW. Additionally it is good to check SW printouts via hyper-terminal (or TeraTerm). These printouts may give a clue about the problem.

Problem: Device cannot boot, TV hangs in standby mode.

Possible causes: No power supply or a problem about software.

Solution: Please check 12V_VCC, 5V_VCC and 3V3_VCC with a voltage-meter. Try to update TV with latest SW. Additionally it is good to check SW printouts via hyper-terminal (or TeraTerm). These printouts may give a clue about the problem.

DVD PROBLEM

Problem: DVD is not working.

Possible causes: A problem in Service menu or no DVD supply voltage.

Solution: Please check that DVD source is selected in Service menu. Please check supply voltage of DVD namely 12V_VCC.

Problem: DVD is not working.

Possible causes: A problem in Service menu or no DVD supply voltage.

Solution: Please check that DVD source is selected in Service menu. Please check supply voltage of DVD namely 12V_VCC.

NO SIGNAL PROBLEM

Problem: No signal in TV mode.

Possible causes: A problem in Service menu or no tuner supply voltage.

Solution: Please check tuner supply voltage; 3V3_TUN. Check tuner options are correctly set in Service menu.

Check AGC voltage at IF_AGC pin of tuner, it should be more than 2V.

Problem: No signal in TV mode.

Possible causes: A problem in Service menu or no tuner supply voltage.

Solution: Please check tuner supply voltage; 3V3_TUN. Check tuner options are correctly set in Service menu.

Check AGC voltage at IF_AGC pin of tuner, it should be more than 2V.